A mold opening and closing machine

A technology of opening and closing molds and mold machines, which is applied in the field of machinery, can solve problems such as high manufacturing costs and complex power mechanisms, and achieve the effect of simple structure and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

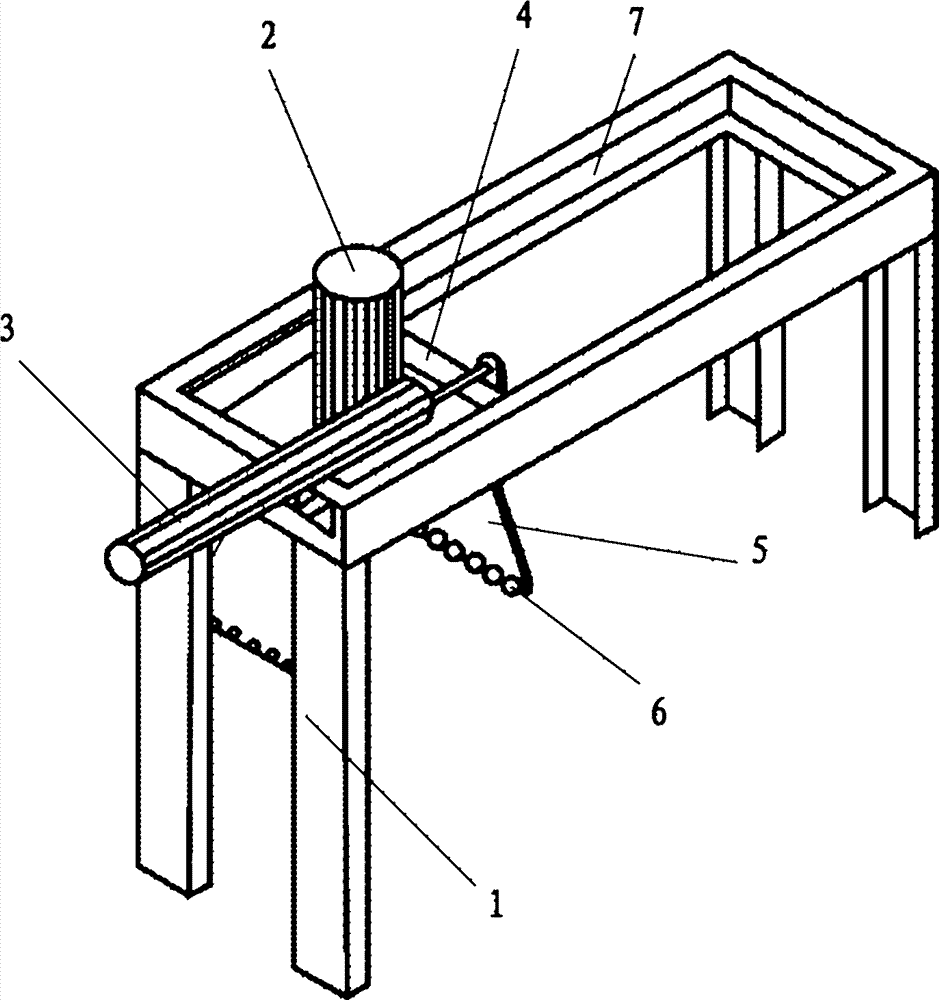

[0019] figure 1 It is a structural schematic diagram of a mold opening and closing machine in the present invention.

[0020] With reference to the accompanying drawings, a kind of mold opening and closing machine that the present invention proposes, comprises fixed frame 1, lifting cylinder 2, stretching cylinder 3, fixed flat car 4, die grabbing frame 5 and roller 6, wherein,

[0021] The fixed bracket 1 plays the role of supporting the whole mold opening and closing machine, and a guide rail 7 is arranged on the fixed frame 1, and the fixed flat car 4 is installed in the guide rail 7;

[0022] The stretching cylinder 3 is used to push and pull the raised mold machine to another track for further processing, including cleaning, sand shooting and other processing. The cylinder barrel of the stretching cylinder 3 is fixed on the fixed frame 1, and its piston rod is fixed on the fixed flat car 4, and the piston rod of the stretching cylinder 3 performs telescopic movement, dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com