Mold stripping machine with two speeds for casting

A technology of ejector and speed, which is applied in the direction of loosening the model, etc., can solve the problems of difficulty, poor control of the ejection speed, and large wrapping force of the model.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0021] The present invention provides a kind of mold-drawing machine for casting with two speeds. During the operation of the mold-drawing machine, the starting speed of the mold-drawing can be very slow, which is beneficial to ensure the quality of the mold-drawing; Help to improve efficiency. The planetary gear train is used to make the mold lifting machine obtain a larger transmission ratio in a small space, so that the equipment structure is simple and the equipment cost is low.

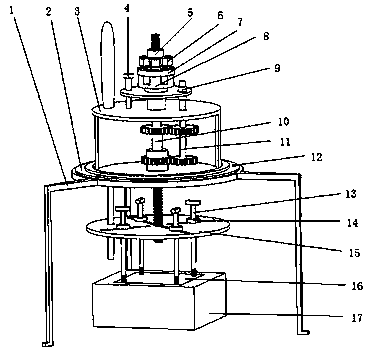

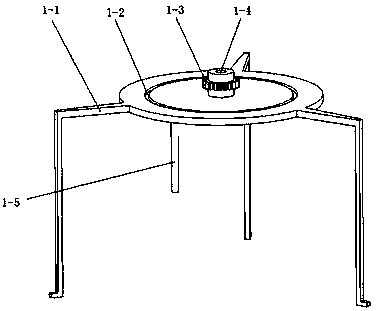

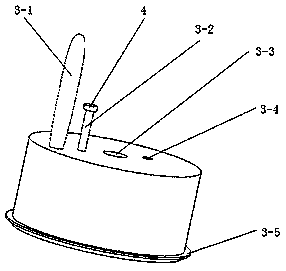

[0022] As an embodiment of the present invention, the present invention provides a mold ejector for casting with two speeds, including a frame 1, a gland 2, a turntable 3, a limit nut 4, a lock nut 5, and an upper chuck 6 , chuck cover 7, lower chuck 8, fixed nut 9, screw shaft 10, duplex planetary gear 11, gland screw 12, ejector screw 13, adjusting nut 14, eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com