Spiral ceramic crystal selector and fabrication process of selector

A technology of spiral crystal separator and manufacturing process, which is applied in the directions of manufacturing tools, crystal growth, single crystal growth, etc. Qualified rate, easy to use, easy to manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

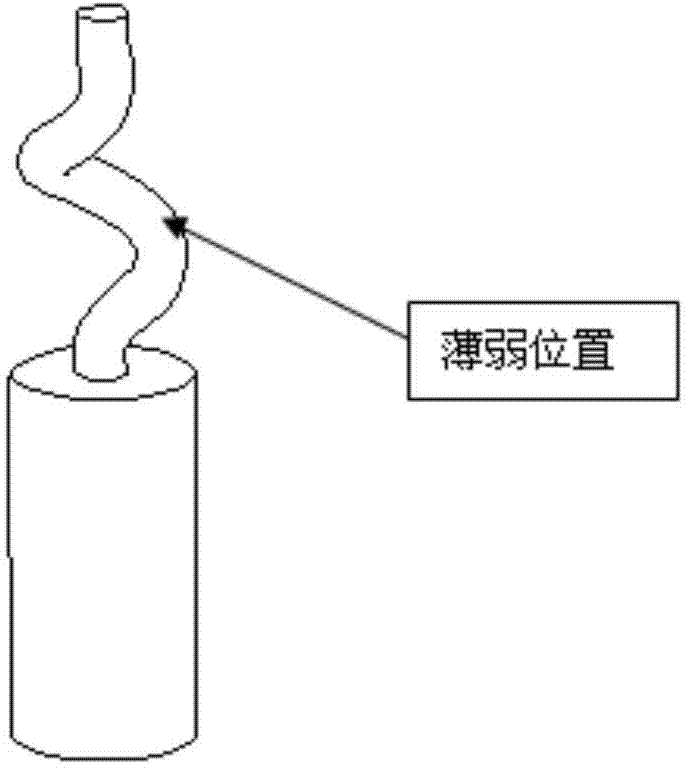

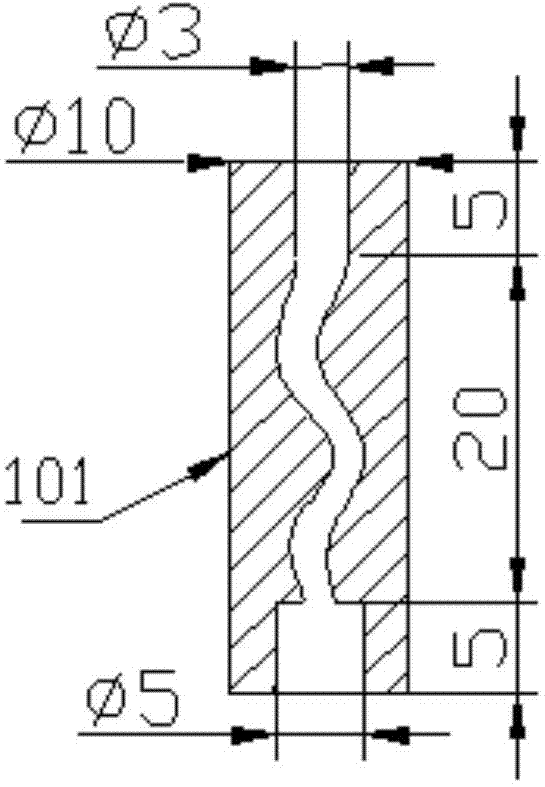

[0023] This embodiment provides a ceramic spiral crystal selector, which is characterized in that: the ceramic spiral crystal selector has a cylindrical structure on the outside, with a spiral through hole inside, and the diameter of the outer structure of the structure is 8mm; the initial section of the internal space The dimensions are 3mm in diameter and 4mm in height; the helix section: the helix angle is 25 degrees, and the helix diameter is 2mm; the extension section: 2mm in diameter and 4mm in height.

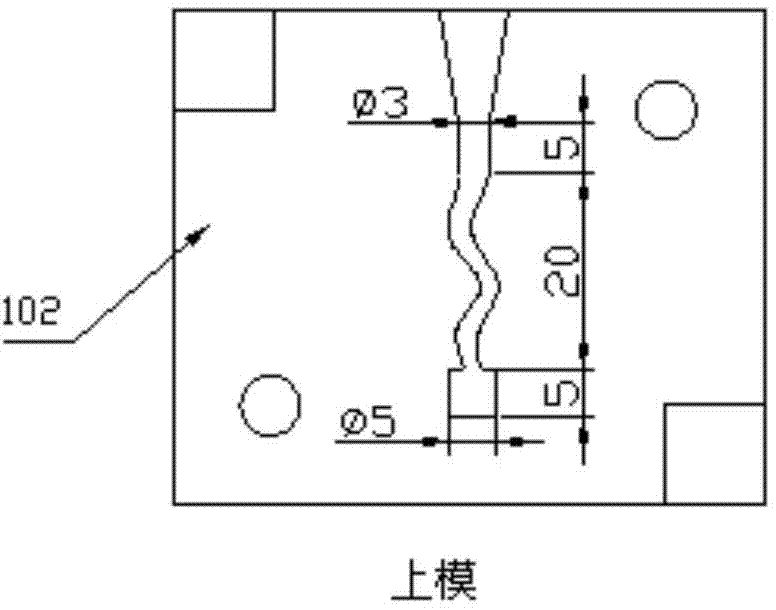

[0024] A manufacturing process of a ceramic spiral crystal selector, characterized in that: the manufacture of the ceramic spiral crystal selector 101 also involves an inner shape production mold set, that is, a mold set, including an upper mold 102, a lower mold 103 and an outer profile Form the mold group that is, comprise left mold 104, right mold 105, upper positioning block 106, lower positioning block 107;

[0025] The manufacturing scheme of ceramic spiral crystal...

Embodiment 2

[0029] This embodiment provides a ceramic spiral crystal selector, which is characterized in that: the ceramic spiral crystal selector has a cylindrical structure on the outside, with a spiral through hole inside, and the diameter of the outer structure of the structure is 12mm; the initial section of the internal space The dimensions are 5mm in diameter and 6mm in height; the helix section: the helix angle is 45 degrees, and the helix diameter is 3mm; the extension section: 4mm in diameter and 8mm in height.

[0030] A manufacturing process of a ceramic spiral crystal selector, characterized in that: the manufacture of the ceramic spiral crystal selector 101 also involves an inner shape production mold set, that is, a mold set, including an upper mold 102, a lower mold 103 and an outer profile Form the mold group that is, comprise left mold 104, right mold 105, upper positioning block 106, lower positioning block 107;

[0031] The manufacturing scheme of ceramic spiral crysta...

Embodiment 3

[0035] This embodiment provides a ceramic spiral crystal selector, which is characterized in that: the ceramic spiral crystal selector has a cylindrical structure on the outside, with a spiral through hole inside, and the diameter of the outer structure of the structure is 15mm; the initial section of the internal space The size is 8mm in diameter and 10mm in height; helix section: helix angle 60 degrees, helix diameter 5mm; extension section: diameter 5mm, height 10mm.

[0036] A manufacturing process of a ceramic spiral crystal selector, characterized in that: the manufacture of the ceramic spiral crystal selector 101 also involves an inner shape production mold set, that is, a mold set, including an upper mold 102, a lower mold 103 and an outer profile Form the mold group that is, comprise left mold 104, right mold 105, upper positioning block 106, lower positioning block 107;

[0037] The manufacturing scheme of ceramic spiral crystal selector 101 is to first use the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com