Manufacturing method of restrictor of engine

A throttle and engine technology, applied in the field of auto parts, can solve the problems of low casting yield, poor valve rigidity, unsatisfactory wear resistance, etc., and achieve the effect of high casting qualification rate, good compactness, and small tendency to loosen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing an engine throttle includes the following steps:

[0025] (1) Make fusible molds and mold shells according to the size of the throttle;

[0026] (2) Baking the shell at 800℃ for 2h;

[0027] (3) Coating metal aluminum on the inner surface of the mold shell, the temperature of the coating film is 800°C, and the cooling method is air cooling;

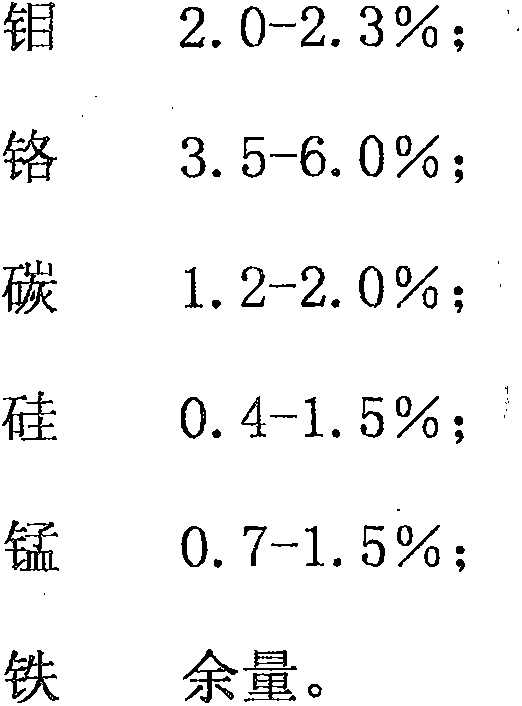

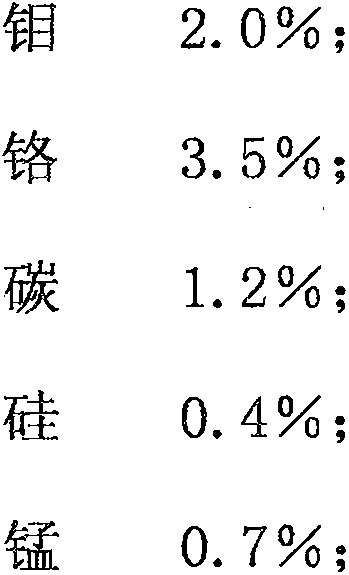

[0028] (4) Configure molten alloy as required, and inject it into the mold shell to obtain a cast body;

[0029] (5) Normalizing and tempering the casting body, and natural cooling;

[0030] (6) The surface of the casting body is oxidized by the discharge oxidation method to obtain a dense aluminum oxide film;

[0031] (7) The casting body is polished to obtain semi-finished products by fine polishing;

[0032] (8) The semi-finished product is subjected to secondary normalizing and tempering in a box-type resistance furnace to obtain a finished product.

[0033] In the step (5) and step (8), the normalizing temperature is ...

Embodiment 2

[0040] A method for preparing an engine throttle includes the following steps:

[0041] (1) Make fusible molds and mold shells according to the size of the throttle;

[0042] (2) Baking the shell at 900℃ for 5h;

[0043] (3) Coating metal aluminum on the inner surface of the mold shell, the temperature of the coating film is 1000°C, and the cooling method is air cooling;

[0044] (4) Configure molten alloy as required, and inject it into the mold shell to obtain a cast body;

[0045] (5) Normalizing and tempering the casting body, and natural cooling;

[0046] (6) The surface of the casting body is oxidized by the discharge oxidation method to obtain a dense aluminum oxide film;

[0047] (7) The casting body is polished to obtain semi-finished products by fine polishing;

[0048] (8) The semi-finished product is subjected to secondary normalizing and tempering in a box-type resistance furnace to obtain a finished product.

[0049] In the step (5) and step (8), the normalizing temperature is...

Embodiment 3

[0056] A method for preparing an engine throttle includes the following steps:

[0057] (1) Make fusible molds and mold shells according to the size of the throttle;

[0058] (2) Baking the shell at 850℃ for 3h;

[0059] (3) Coating metal aluminum on the inner surface of the mold shell, the temperature of the coating film is 900°C, and the cooling method is air cooling;

[0060] (4) Configure molten alloy as required, and inject it into the mold shell to obtain a cast body;

[0061] (5) Normalizing and tempering the casting body, and natural cooling;

[0062] (6) The surface of the casting body is oxidized by the discharge oxidation method to obtain a dense aluminum oxide film;

[0063] (7) The casting body is polished to obtain semi-finished products by fine polishing;

[0064] (8) The semi-finished product is subjected to secondary normalizing and tempering in a box-type resistance furnace to obtain a finished product.

[0065] In the step (5) and step (8), the normalizing temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com