Blowing-suction integrated cleaning device and method for aviation blade and complex component mold shell

A technology for aviation blades and cleaning devices, which is applied in cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., and can solve the problem of complex inner cavity circuits of mold shells, complex inner cavity structures of mold shells, and difficulties in cleaning out debris, etc. problems, to achieve the effect of improving cleaning operation efficiency, considerable economic benefits, and improving casting pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

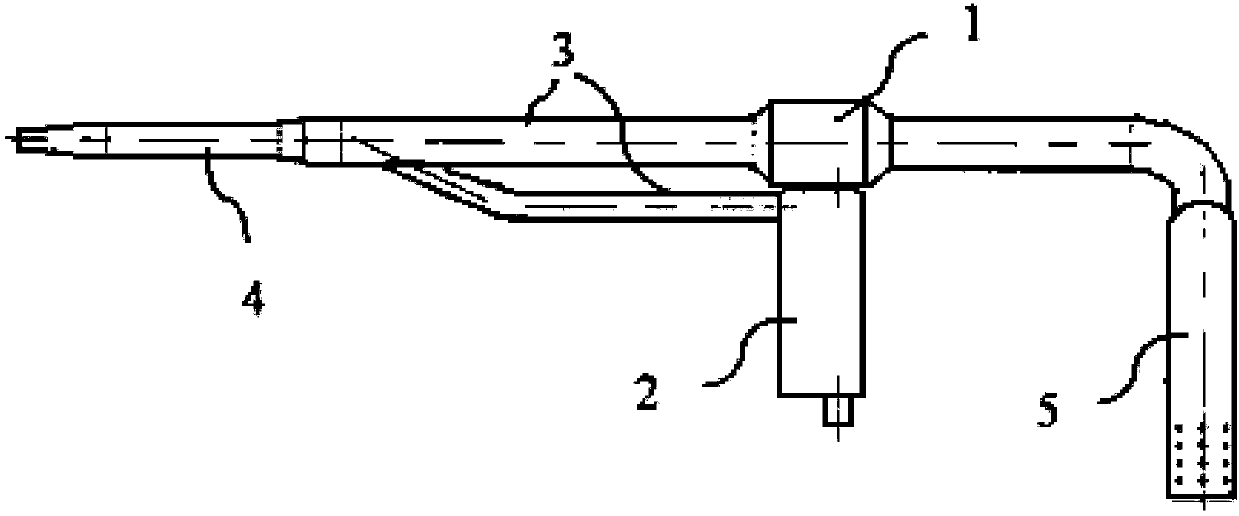

[0032] A blow-suction integrated cleaning device for aviation blades and complex component shells, as attached figure 1 As shown; its composition is as follows: vortex suction mechanism 1, gas circuit control mechanism 2, blowing and sucking front pipe 3, blowing and sucking nozzle head 4 and blowing and sucking tail pipe 5; wherein:

[0033] The blowing and suction nozzle head 4 is arranged at the front end of the whole device; the blowing and suctioning front pipe 3 has two parallel air circuits: the main air circuit and the branch air circuit; the tubular main air circuit and the tubular blowing and suctioning pipe 3 The nozzles 4 are coaxially fixedly connected in sequence; the tubular main gas path in the front tube 3 is far away from the blowing nozzle 4 and is connected with the vortex suction mechanism 1 at the same time to form a coaxial structure; the gas circuit control mechanism 2 simultaneously It is connected with the branch air path of the front pipe 3 and the v...

Embodiment 2

[0042] Aviation blades and complex component shells are cleaned by blowing and suction integrated cleaning method, which uses a special aviation blade and complex component shells to be cleaned by a blowing and suction integrated cleaning device; the aviation blades and complex component shells are cleaned by a blowing and suction integrated cleaning device The composition is as follows: vortex suction mechanism 1, gas circuit control mechanism 2, blowing and suction front pipe 3, blowing and suction nozzle head 4 and blowing and suction tail pipe 5; among them:

[0043] The blowing and suction nozzle head 4 is arranged at the front end of the whole device; the blowing and suctioning front pipe 3 has two parallel air circuits: the main air circuit and the branch air circuit; the tubular main air circuit and the tubular blowing and suctioning pipe 3 The nozzles 4 are coaxially fixedly connected in sequence; the tubular main gas path in the front tube 3 is far away from the blowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com