Large-duty loader hydraulic valve body casting

A loader and hydraulic valve technology, which is applied in the field of large loader hydraulic valve body castings, can solve the problems of hydraulic valves not working stably, valve body leakage, and large wear, and achieve reasonable and compact structure, low casting cost and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

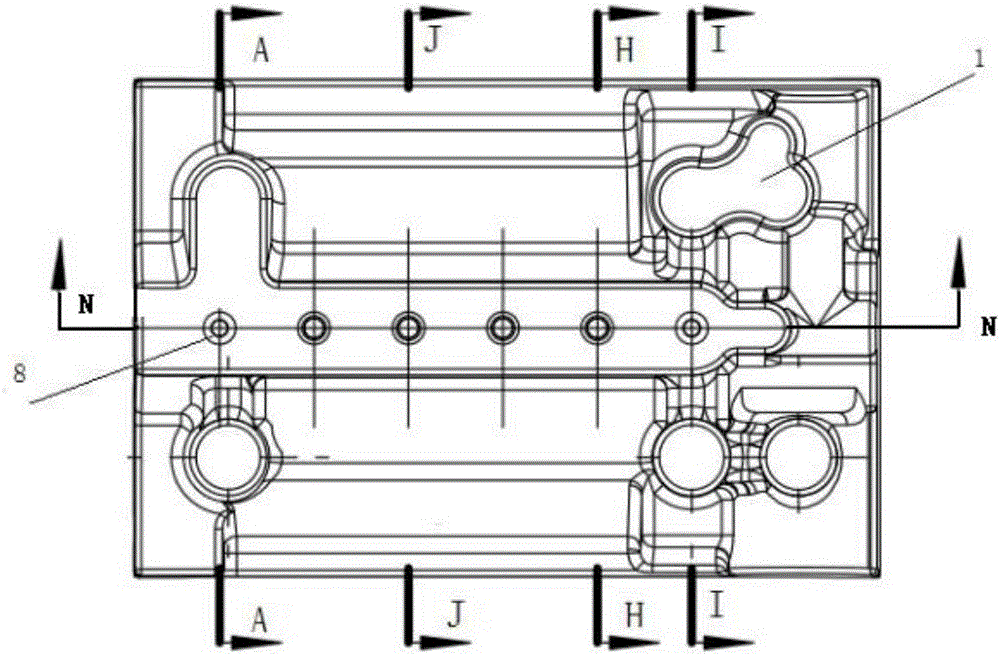

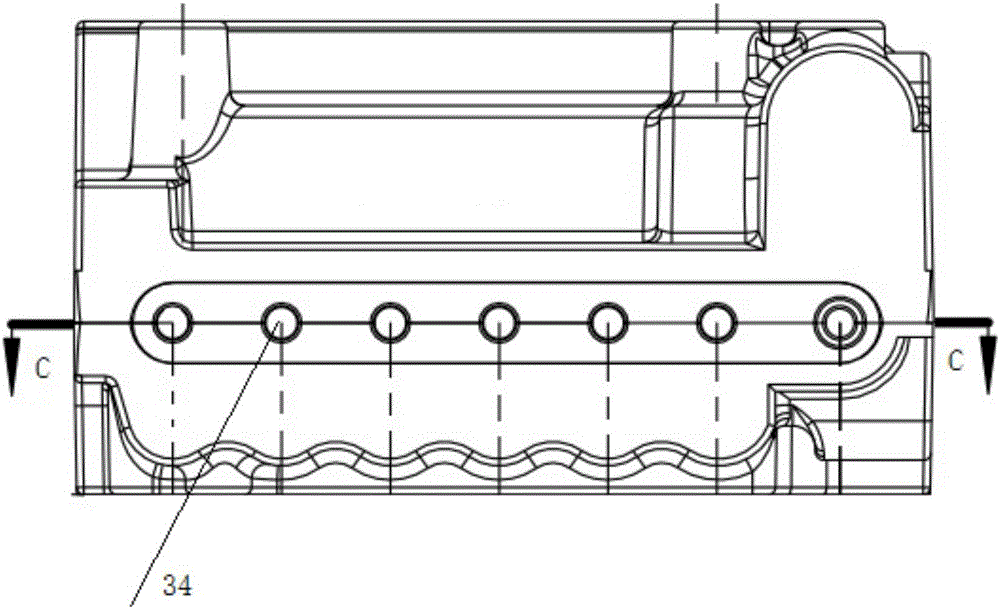

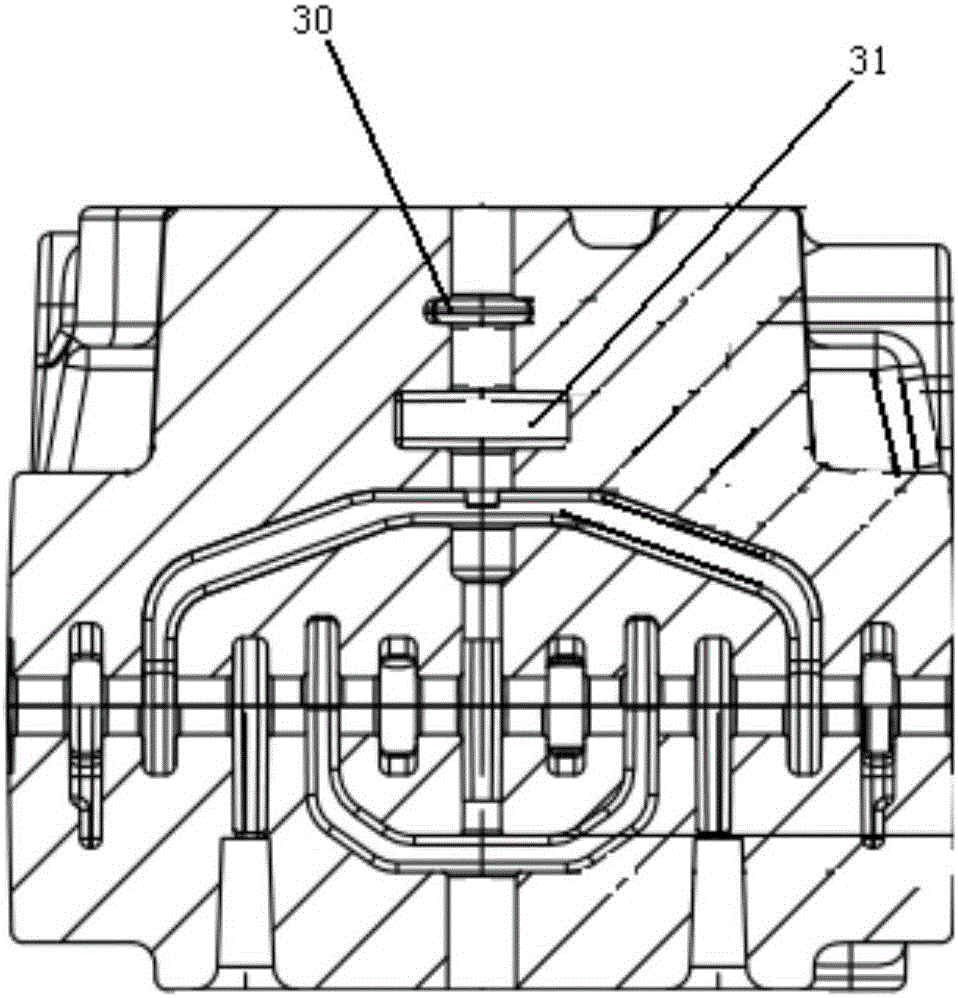

[0032] see Figure 1-Figure 8 , the present invention provides a hydraulic valve body casting for a large loader, including a valve body 1, a vertical flow path, a horizontal flow path, an auxiliary flow path and a flow path opening;

[0033] The vertical flow channels include the first vertical flow channel 2, the second vertical flow channel 3, the third vertical flow channel 4, the fourth vertical flow channel 5, the fifth vertical flow channel 6 and the sixth vertical flow channel arranged in sequence from left to right. Vertical flow channels 7, the vertical flow channels are arranged on the same plane and parallel to each other, the upper and lower surfaces of the valve body 1 are respectively provided with six first flow channel openings 8 and six second flow channel openings 9, and are connected with the six vertical flow channels One-to-one correspondence, the upper ends of the six vertical flow channels communicate with the first flow channel opening 8, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com