Manufacturing method of super duplex stainless steel single-stage double-suction centrifugal pump case

A duplex stainless steel, single-stage double-suction technology, applied in the direction of manufacturing tools, casting molding equipment, furnaces, etc., can solve the problems of high brittleness tendency, high temperature sensitivity, concentration, etc., improve the pass rate and optimize the casting process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

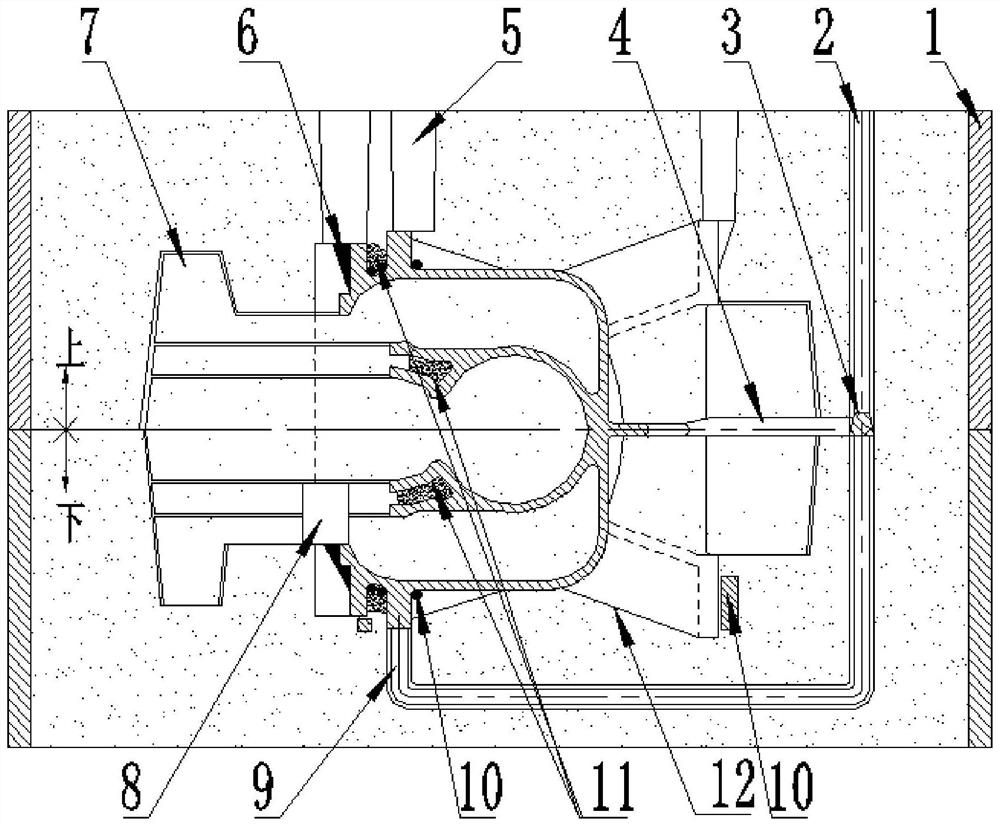

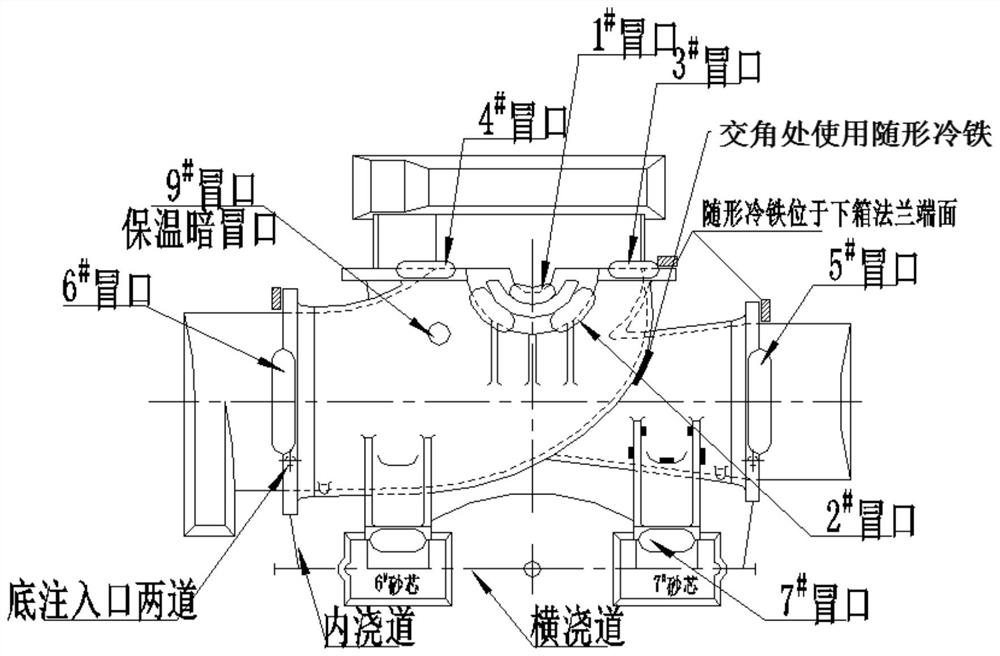

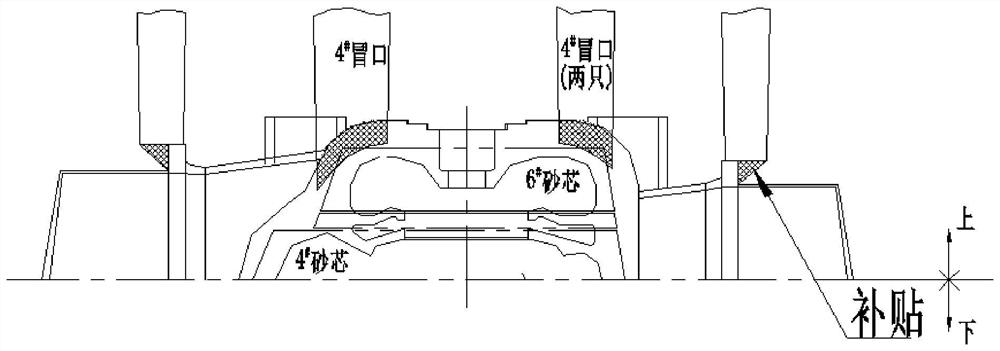

[0025] The reference signs in the drawings of the specification include: sand box 1, sprue 2, runner 3, inner runner 4, open top riser 5, riser subsidy 6, sand core 7, hidden riser 8, bottom Sprue 9, conformal chill iron 10, chromite basic phenolic resin sand use part 11, casting 12.

[0026] The casting process method of the present invention is composed of stages such as smelting, casting, unpacking, gas cutting riser, etc., the following in conjunction with the attached Figure 1~4 The present invention is described in further detail.

[0027] The manufacturing method of the pump casing of the present invention can effectively prevent cracks, specifically, as figure 1 As shown in the combined box diagram, the sand core 7 adopts self-hardening alkaline phenolic resin new sand to improve the strength of the sand core 7 (≥0.6Mpa), and the pouring system (sprue 2 made of ceramic mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com