Electrohydraulic valve body casting

An electro-hydraulic valve and valve body technology, which is applied in the directions of casting molds, valve details, valve devices, etc., can solve the problems of side hole fracture and deformation, main hole fracture, casting difficulties, etc., to improve casting qualification rate, reduce casting cost, The effect of easy casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

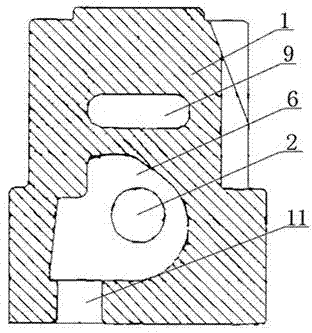

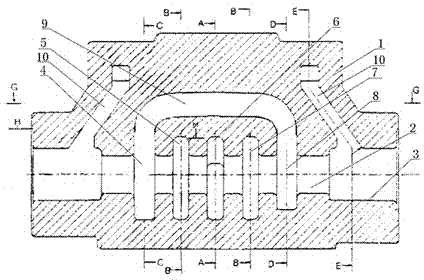

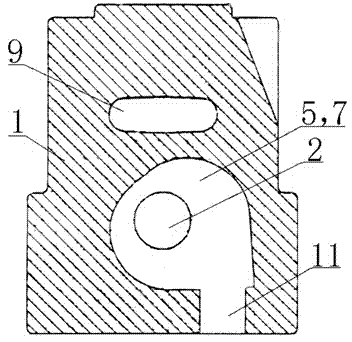

[0020] In order to further illustrate the present invention, illustrate below in conjunction with accompanying drawing of description:

[0021] Referring to the accompanying drawings, the body casting of the electro-hydraulic valve includes a valve body 1, a lateral flow channel 2, a flow channel opening 3 and an auxiliary flow channel 9. A horizontal flow channel 2 is designed in the valve body 1, and the two ends of the horizontal flow channel 2 are open. There is a flow channel opening 3, and there are five annular circular grooves in the middle of the transverse flow channel 2, which are the first annular groove 4, the second annular groove 5, the third annular groove 6, the fourth annular groove 7 and the fifth annular groove 8, The first annular groove 4 and the fifth annular groove 8 communicate through the auxiliary flow channel 9, which is located at the upper end of the transverse flow channel 2, and the upper end of the inner side of the flow channel opening at both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com