Mixing-type pouring device and casting technology for support castings

A mixed type and casting technology, which is applied in the field of casting manufacturing, can solve the problems that multiple cavities cannot be guaranteed to be filled at the same time, the product performance difference is large, and the temperature difference is large, so as to reduce sand washing defects, simple and short runners, and metal The effect of less liquid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

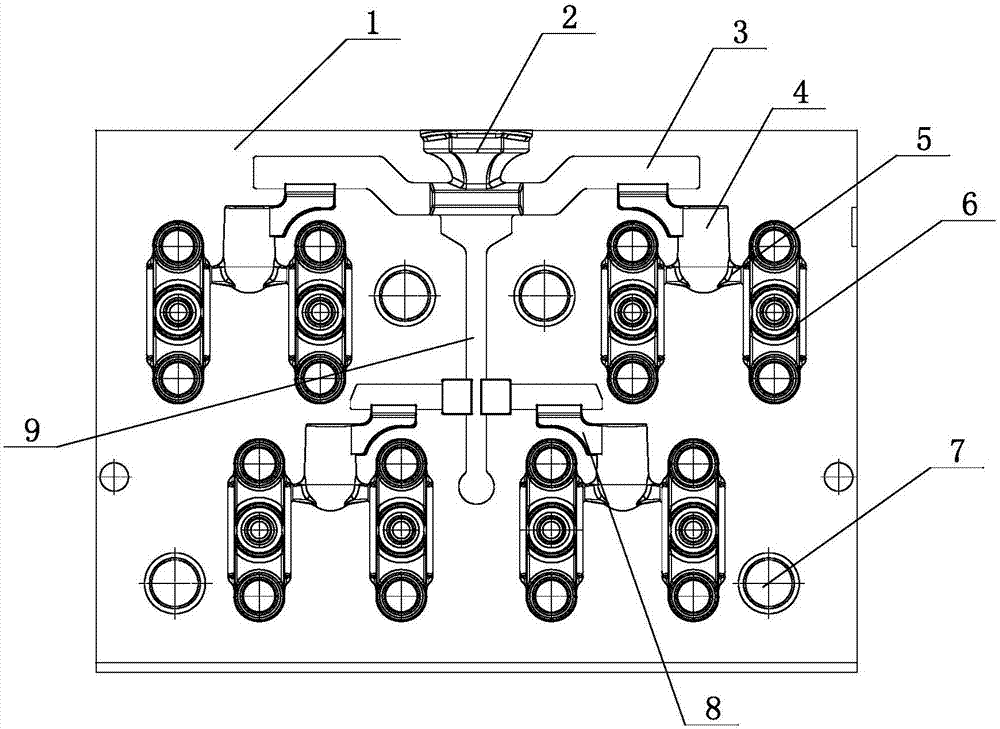

[0028] Such as figure 1 As shown, the bracket casting hybrid pouring device of the present invention includes a template 1, a sprue cup 2 is arranged on the top of the template 1, and a plurality of bracket patterns 6 are arranged on the template 1, and the template 1 and the bracket patterns 6 pass through the horizontal The runners are connected, and the runners are divided into horizontal runners 3 and vertical runners 9. The horizontal runner 3 is a high trapezoidal section, which has a good slag avoidance effect, reduces product slag holes, and improves product qualification. The vertical runner 9 is a standard trapezoidal cross-section, which has good transmission capacity, improves the filling capacity of molten iron, and can be poured at a lower temperature. The support pattern 6 is externally connected to the riser 4, and the riser 4 is connected to the support pattern 6 is connected through the riser neck 5, the riser neck 5 can also serve as an ingate, the riser 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com