A low-pressure metal mold for an aluminum flywheel housing

A metal mold and flywheel shell technology, applied in the field of low-pressure metal molds, can solve the problems of large riser removal workload, many pores under the surface, difficulties and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

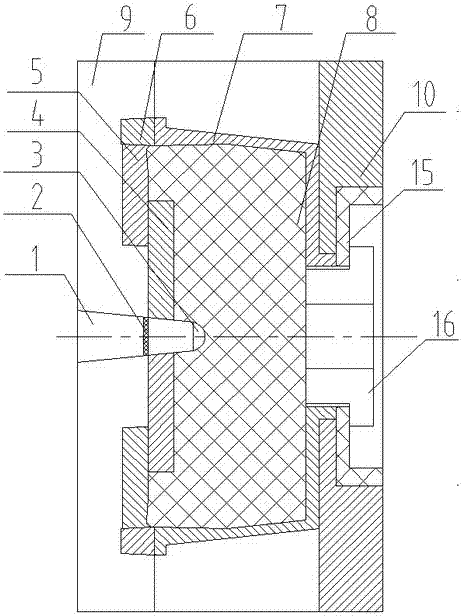

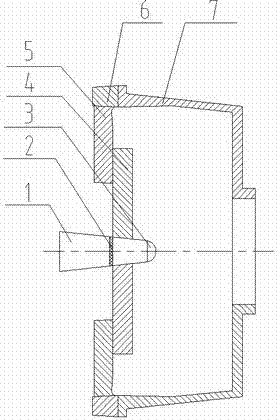

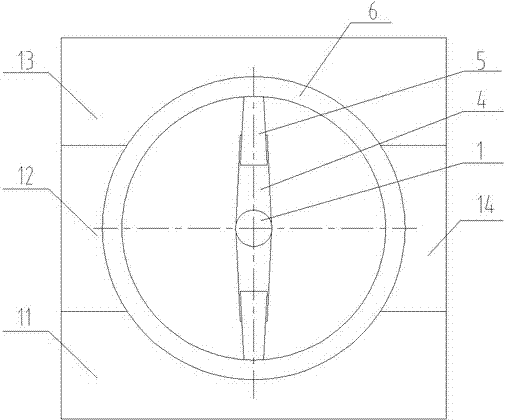

[0018] figure 1 , 2 , 3, the present invention includes a metal mold surrounded by an upper mold 10, a side module one 11, a side module two 12, a side module three 13, a side module four 14 and a bottom mold 9, and a mold cavity located in the metal mold. Partial cavity in the sand core 8. The bottom of the bottom mold 9 is provided with a sprue (gate) 1 , an annular inner runner 6 , and an upper runner 5 . The bottom of the sand core 8 is provided with a lower runner 4 . Side module one 11, side module two 12, side module three 13, and side module four 14 form the peripheral shape of the aluminum alloy flywheel shell, and an air cooling system (blowing air cooling system) is provided on the side module two 12 and the side module four 14 that form the shape of the suspended surface. air cooling system). The shape of the gear chamber cavity of the upper mold adopts the form of an integral conformal insert 15, which better ensures the smooth exhaust of the upper mold cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com