Turbine blade trailing edge fold line type exhaust split seam structure

A turbine blade and trailing edge technology, which is applied in the direction of blade support components, engine components, machines/engines, etc., can solve problems such as large flow resistance, low cooling effect, and damage to blade structural strength, so as to achieve smooth flow and reduce flow Effects of resistance, loss, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

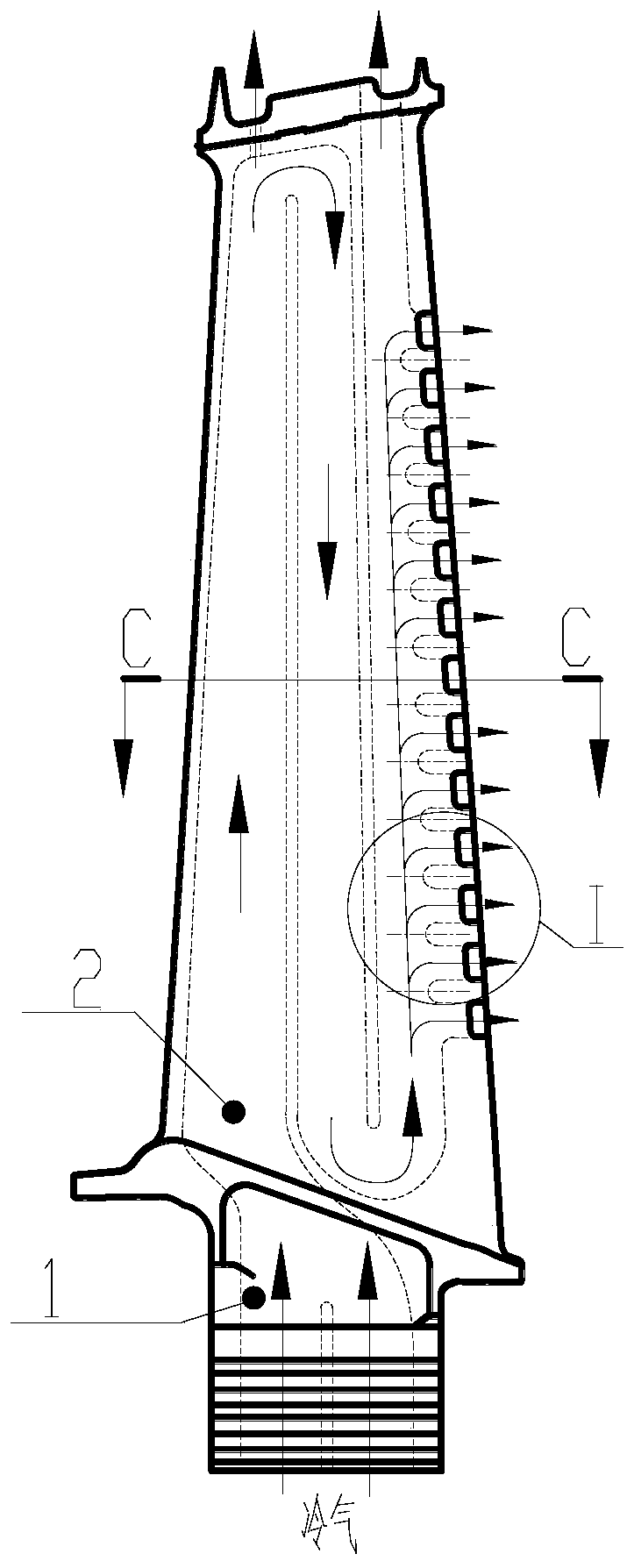

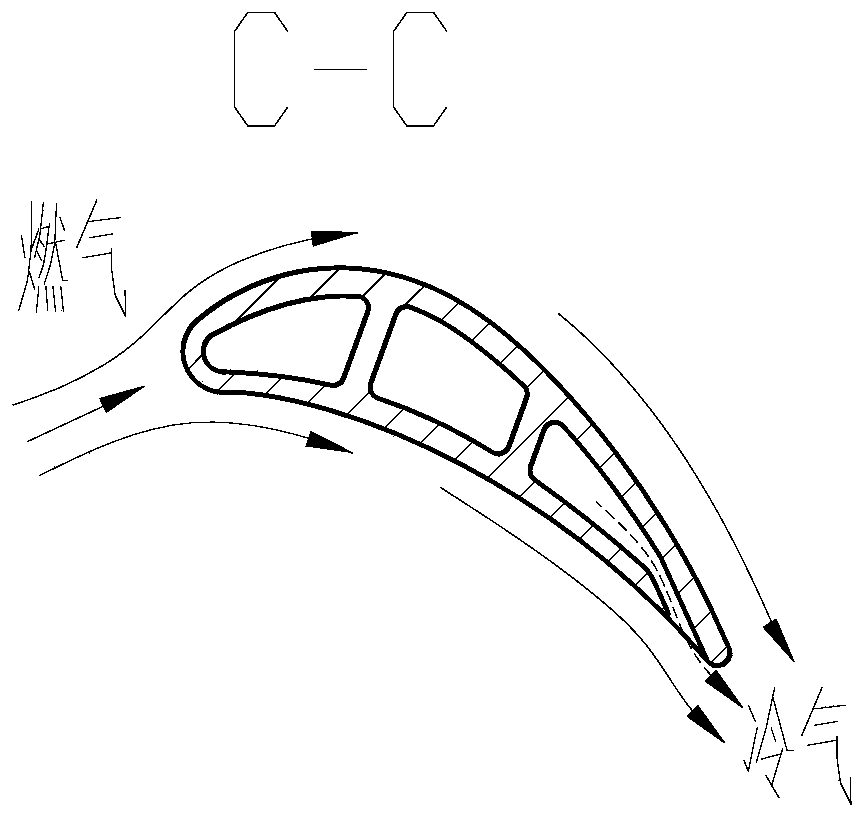

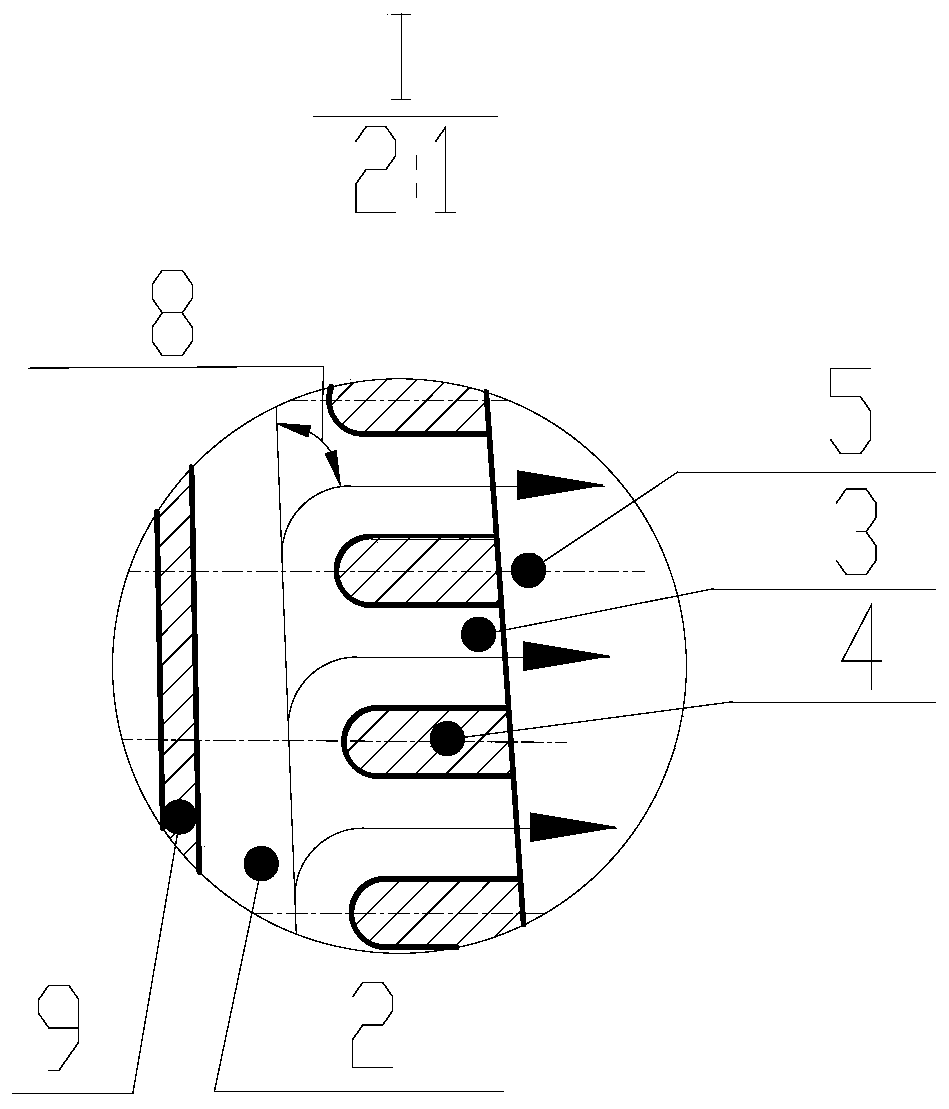

[0036] Please refer to FIG. 2 , a turbine blade trailing edge broken-line exhaust splitting structure, including a hollow turbine blade 1, an inner cavity cold air channel 2, a trailing edge exhaust splitting channel 3 and a trailing edge splitting rib 4;

[0037] The interior of the hollow turbine blade 1 is provided with an inner cavity cold air passage 2, and the trailing edge of the hollow turbine blade 1 is provided with side-by-side trailing edge split ribs 4, and the trailing edge split ribs 4 arranged side by side form a trailing edge row The gas splitting channel 3, the structure of the trailing edge splitting rib 4 forms a broken line shape, and its shape is controlled by the center line 5 of the rib, and the center line 5 of the rib is connected by at least two line segments with different angles, and wherein At least one section is inclined relative to the horizontal plane, and the width of the split rib 4 at the trailing edge is symmetrically distributed along the ...

Embodiment 2

[0039] Please refer to FIG. 2 , a turbine blade trailing edge broken-line exhaust splitting structure, including a hollow turbine blade 1, an inner cavity cold air channel 2, a trailing edge exhaust splitting channel 3 and a trailing edge splitting rib 4;

[0040] The interior of the hollow turbine blade 1 is provided with an inner cavity cold air passage 2, and the trailing edge of the hollow turbine blade 1 is provided with side-by-side trailing edge split ribs 4, and the trailing edge split ribs 4 arranged side by side form a trailing edge row The gas splitting channel 3, the structure of the trailing edge splitting rib 4 forms a broken line shape, and its shape is controlled by the center line 5 of the rib, and the center line 5 of the rib is connected by at least two line segments with different angles, and wherein At least one section is inclined relative to the horizontal plane, and the width of the split rib 4 at the trailing edge is symmetrically distributed along the ...

Embodiment 3

[0042] Please refer to FIG. 2 , a turbine blade trailing edge broken-line exhaust splitting structure, including a hollow turbine blade 1, an inner cavity cold air channel 2, a trailing edge exhaust splitting channel 3 and a trailing edge splitting rib 4;

[0043] The interior of the hollow turbine blade 1 is provided with an inner cavity cold air passage 2, and the trailing edge of the hollow turbine blade 1 is provided with side-by-side trailing edge split ribs 4, and the trailing edge split ribs 4 arranged side by side form a trailing edge row The gas splitting channel 3, the structure of the trailing edge splitting rib 4 forms a broken line shape, and its shape is controlled by the center line 5 of the rib, and the center line 5 of the rib is connected by at least two line segments with different angles, and wherein At least one section is inclined relative to the horizontal plane, and the width of the split rib 4 at the trailing edge is symmetrically distributed along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com