Integrated casting design method for controlling miscellaneous crystals of single crystal blade edge plate

A single crystal blade and design method technology, applied in the direction of casting molding equipment, mold, mold composition, etc., can solve the problem of limited control of miscellaneous crystal defects in single crystal blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

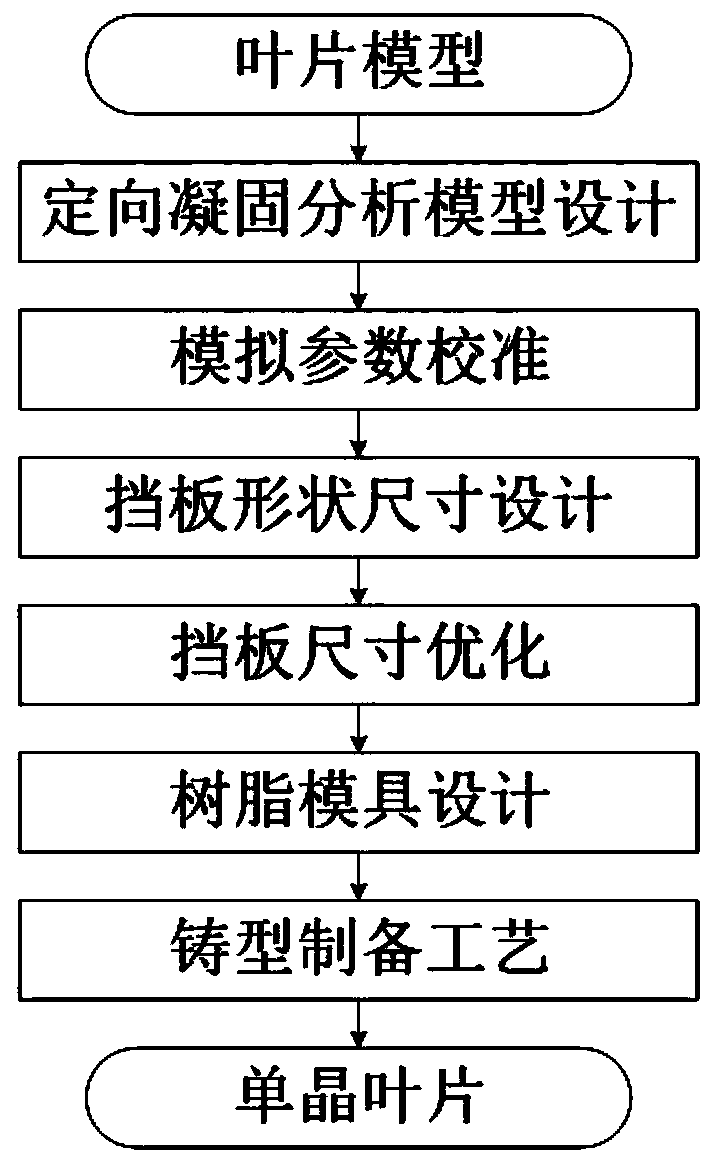

[0051] A method for controlling miscellaneous crystals on the edge plate of a single crystal blade through integrated casting mold design, comprising the following steps:

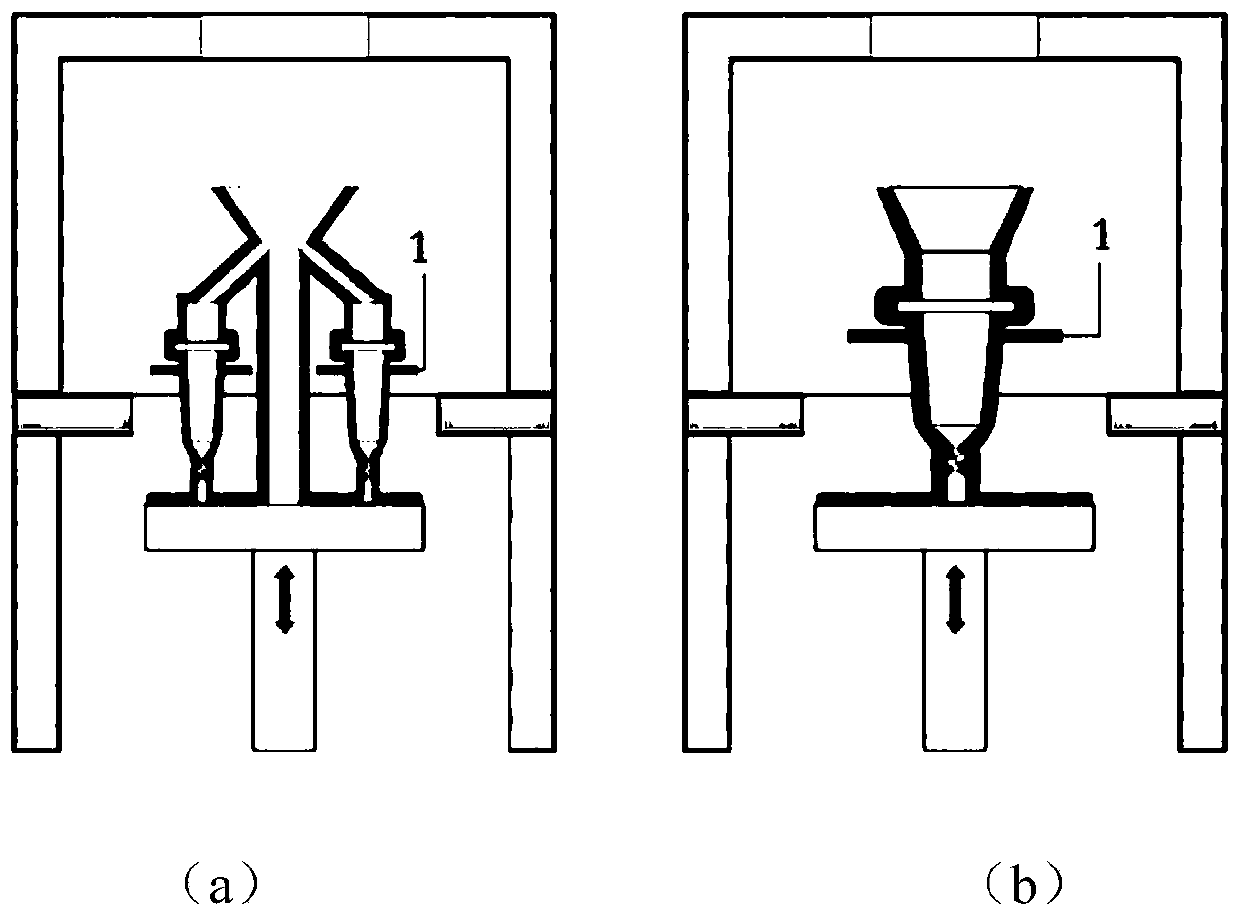

[0052] 1) Design the three-dimensional model of the casting system according to the blade structure, including castings, molds and simplified furnace wall and water cooling plate models

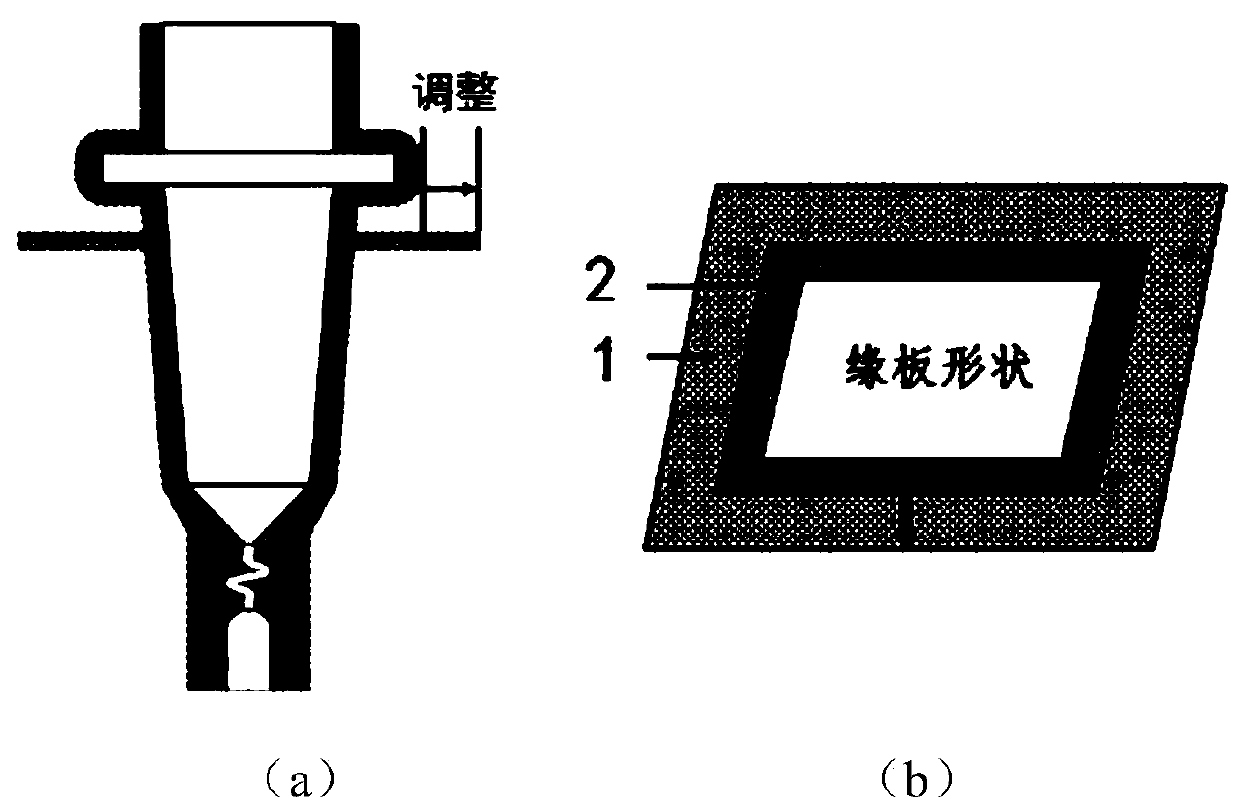

[0053] Firstly, use NX modeling software to design the spiral crystal selector. After the spiral crystal selector transitions smoothly with the top of the blade, the number and position of the modules are arranged according to the size of the water cooling plate. Good heat dissipation between the blades is required. Conditions, after completing the arrangement of the blades on the water cooling plate, design the pouring riser and flow channel, and then complete the design of the entire casting model. Design the casting mold model based on the casting model, and it is required to control the uniform wall thickness of 6-7mm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com