Flash scratchproof protection film and preparation method thereof

A technology of protective film and glitter powder, applied in chemical instruments and methods, lamination, coating and other directions, to achieve the effect of easy operation, strong fashion sense and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

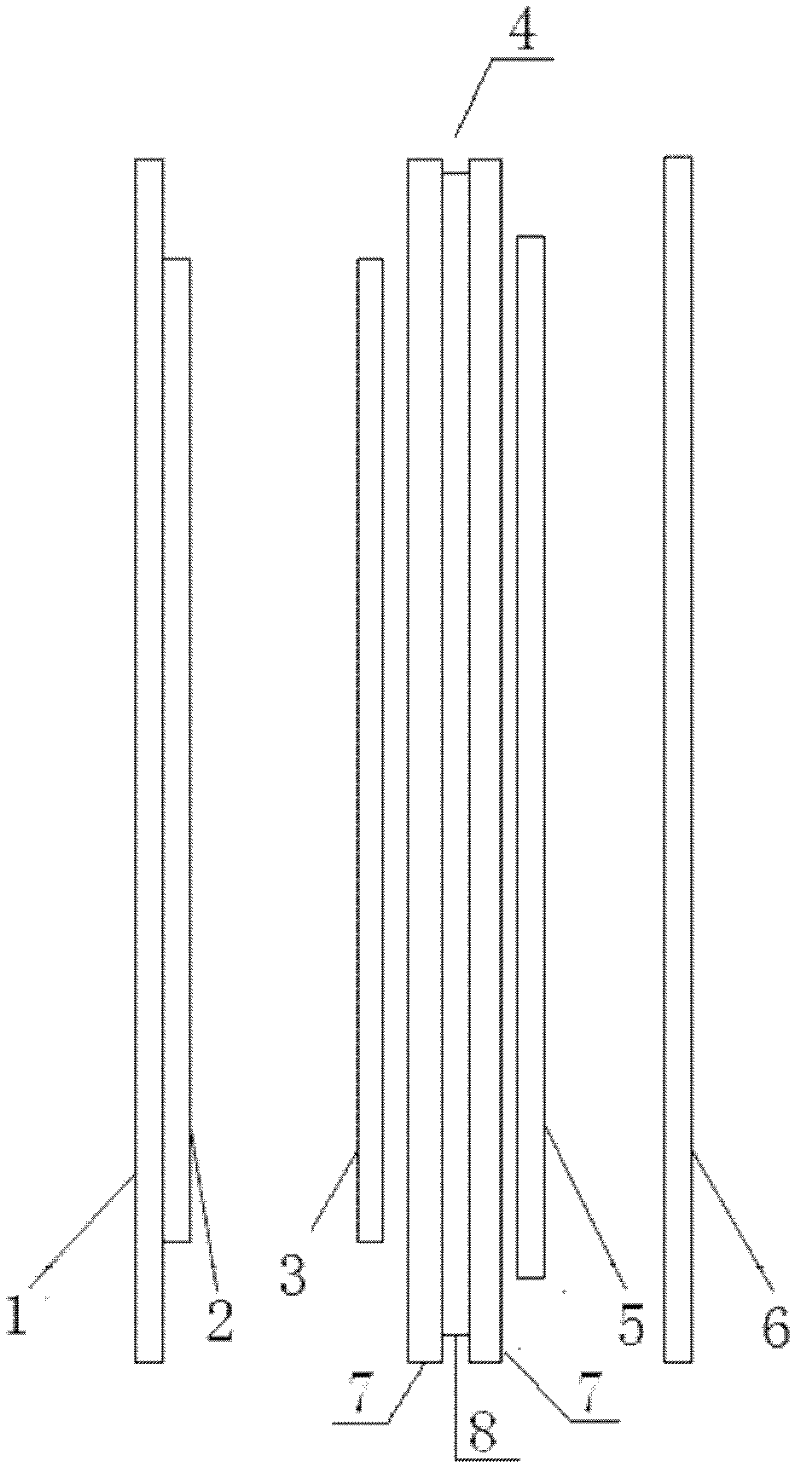

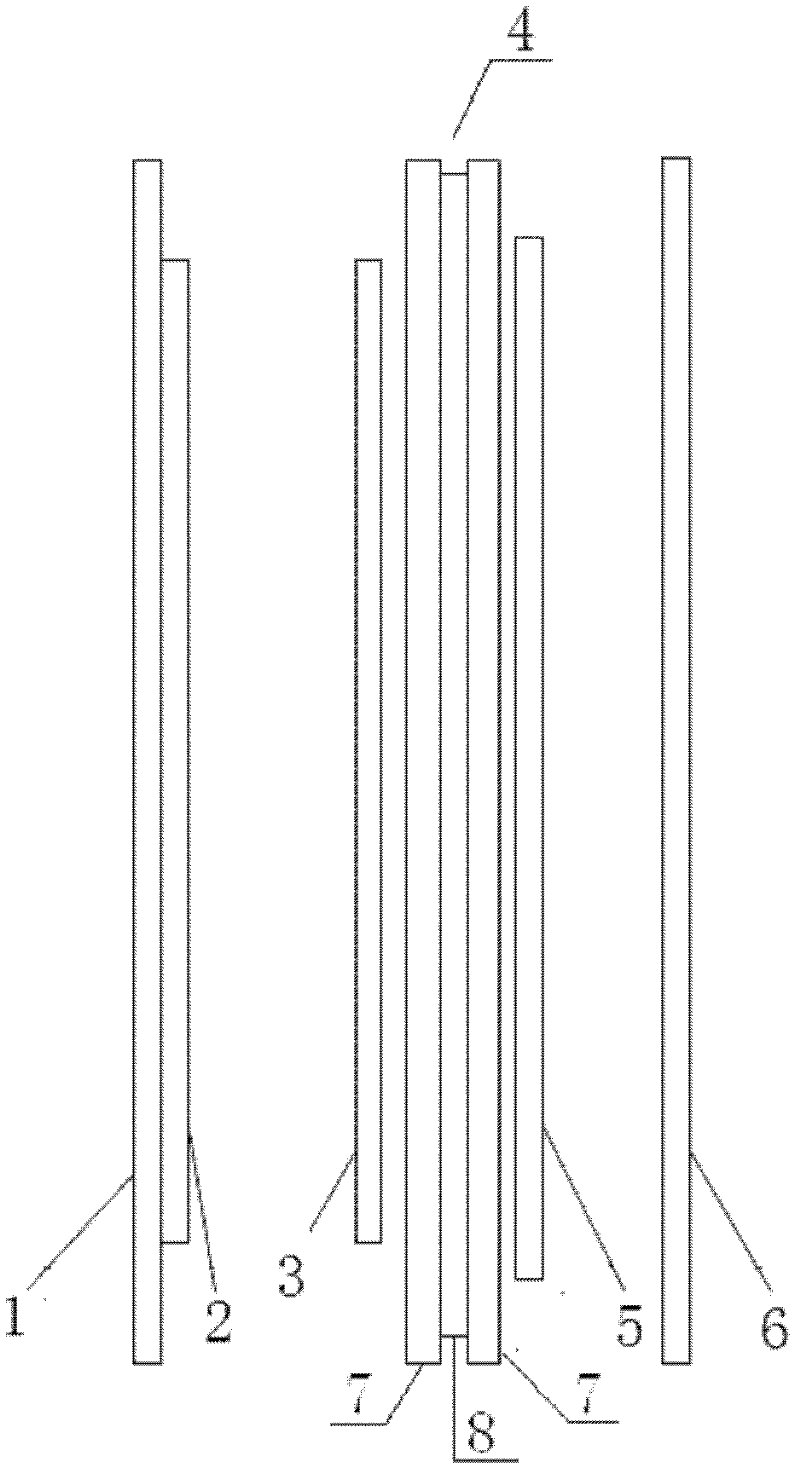

[0045] A flashing anti-scratch car protective film, which includes: a composite main film PET substrate 4 with a thickness of 205um, an installation adhesive layer 5 with a thickness of 25um, an installation adhesive protective film PET substrate 6 with a thickness of 50um, and an adhesive layer with a thickness of 5um. Diamond glitter anti-scratch layer 3, protective film adhesive layer 2 with a thickness of 5um and scratch-resistant layer protective film PET substrate 1 with a thickness of 50um, wherein the composite main film PET substrate 4 includes a double-layered main film PET with a thickness of 100um The substrate 7 and the 5um composite adhesive layer 8 provided therebetween; in this embodiment, the protective film adhesive layer 2 is made of acrylic resin, and the installation adhesive layer 5 is made of a pressure-sensitive adhesive hydroxyacrylic resin It is made of pressure-sensitive adhesive, and the anti-scratch diamond flashing layer 3 is made of heat-cured acr...

Embodiment 2

[0053] A flashing anti-scratch screen protective film, which includes: a diamond flashing composite main film PET base material 4 with a thickness of 108um, a colored transparent installation adhesive layer 5 with a thickness of 5um, a PET base material 6 with an installation adhesive protection film with a thickness of 12um, A scratch-resistant layer 3 with a thickness of 20um, a protective film adhesive layer 2 with a thickness of 10um, and a scratch-resistant protective film PET substrate 1 with a thickness of 36um; wherein, the composite main film PET substrate 4 includes a double-layered main film with a thickness of 50um The composite adhesive layer 8 of 8um that is provided with between PET substrate 7 and; Protective film adhesive layer 2 and installation adhesive layer 5 adopt in the present embodiment are all made of organic silicon resin; What anti-scratch layer 3 adopts is It is made of polyurethane acrylic light curing resin; the composite adhesive layer 8 is made ...

Embodiment 3

[0061] A flashing anti-scratch car protective film, which includes: a composite main film PET base material 4 with a thickness of 78um, a color flashing installation adhesive layer 5 with a thickness of 15um, an installation adhesive protective film PET base material 6 with a thickness of 12um, 25um scratch-resistant layer 3, protective film adhesive layer 2 with a thickness of 10um, and scratch-resistant layer protective film PET substrate 1 with a thickness of 36um; wherein, the composite main film PET substrate 4 includes a double-layered main film PET substrate with a thickness of 29um Material 7 and the composite adhesive layer 8 of 20um that are provided with between; What protective film adhesive layer 2 adopts in the present embodiment is to be made of organic silicon resin, and the pressure-sensitive adhesive hydroxyacrylic acid that color flash installation adhesive layer 5 adopts It is made of resin pressure-sensitive adhesive; the anti-scratch layer 3 is made of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com