Outer ring type efficient start system for self-priming pump and start method thereof

A high-efficiency start-up and self-priming pump technology, which is applied to components, pumps, and drive pumps of pumping devices for elastic fluids, can solve problems such as high manufacturing and operating costs, and poor applicability of jet-type self-priming pumps. Easy processing, obvious energy saving effect, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

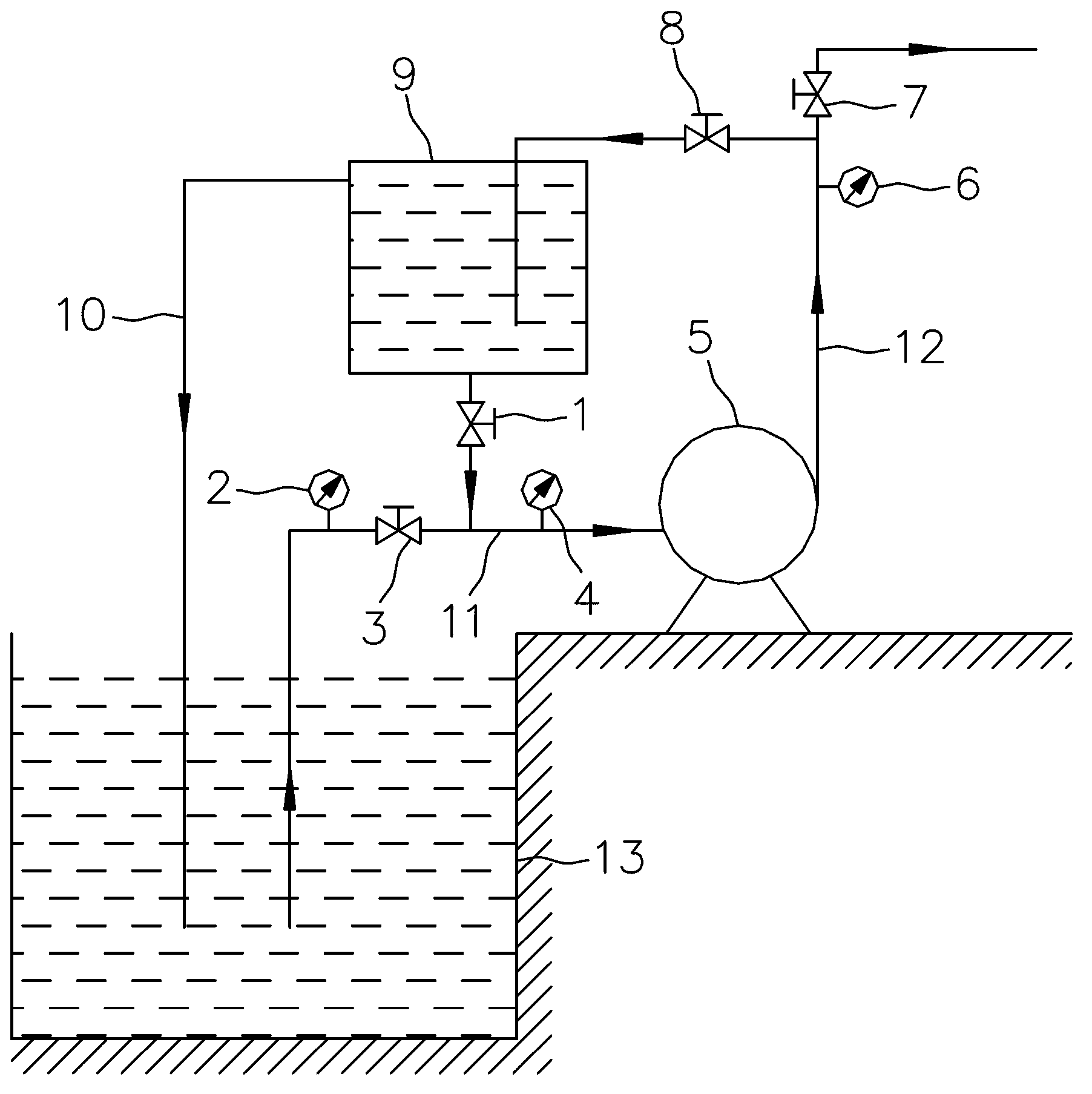

[0074] like figure 1 As shown, the rated flow rate of the main pump is 12.5m 3 / h, rated head 32m, self-priming height 5m. The outer ring type high-efficiency start-up system in this embodiment does not contain a control device, and only an overflow pipe 10 is provided on the gas-liquid separation tank 9 .

[0075] 1) Close the pump inlet regulating valve 3 and the pump outlet regulating valve 7, open the tank inlet regulating valve 8 and the tank outlet regulating valve 1, start the main pump 5, and make the water circulate between the main pump 5 and the gas-liquid separation tank 9;

[0076] 2) When the tank outlet regulating valve 1 is fully open, gradually adjust the opening of the tank inlet regulating valve 8 so that the third pressure detection device 6 displays the rated pressure value of the main pump as 0.32MPa;

[0077] 3) Then gradually adjust the opening of the tank outlet regulating valve 1 to adjust the pressure value displayed by the second pressure detectio...

Embodiment 2

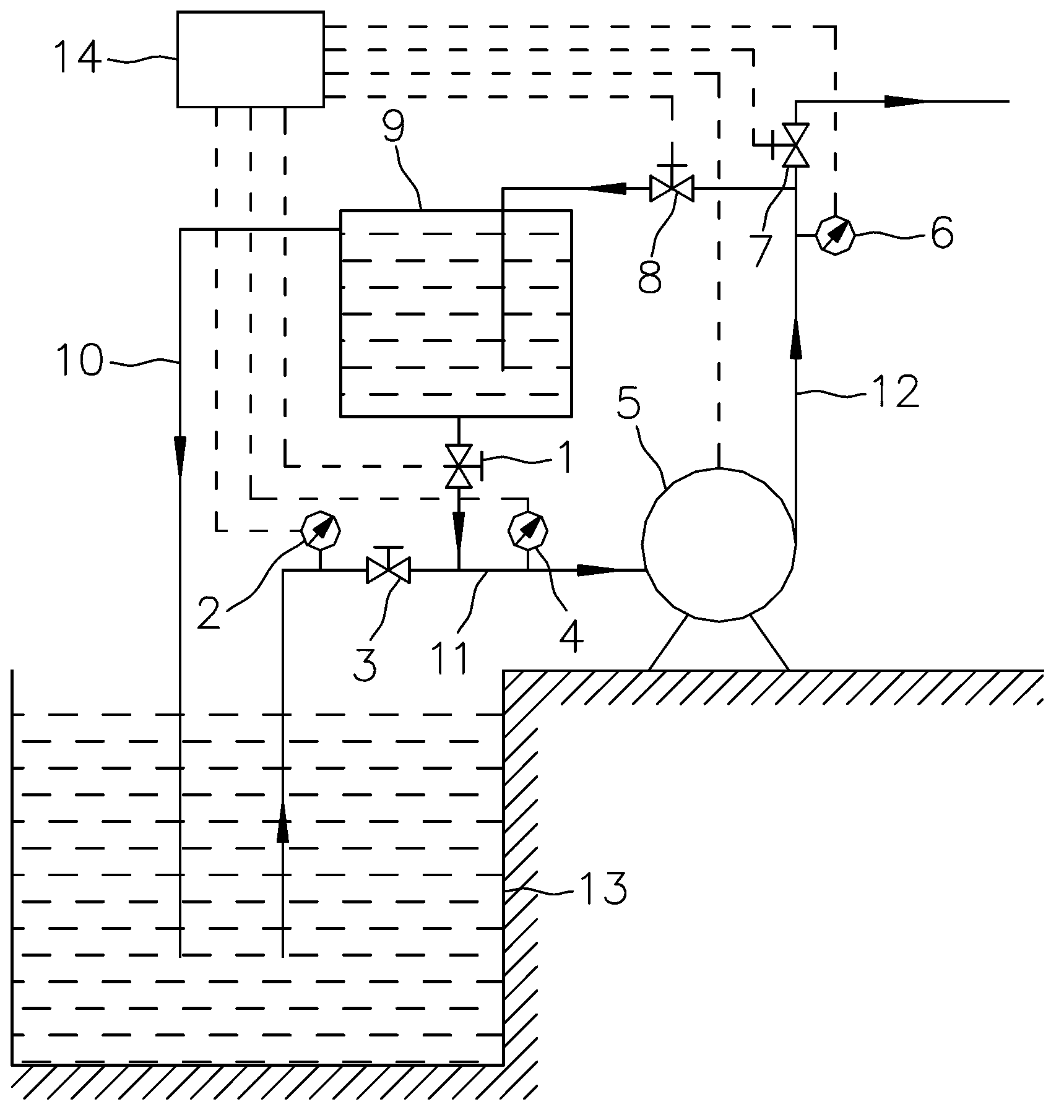

[0080] like figure 2 As shown, the rated flow rate of the main pump is 12.5m 3 / h, rated head 32m, self-priming height 5m. The outer ring type high-efficiency start-up system in this embodiment includes a control device, and a liquid level detection device is installed on the gas-liquid separation tank 9 . The pump inlet regulating valve 3, the pump outlet regulating valve 7, the tank inlet regulating valve 8 and the tank outlet regulating valve 1 are all electric regulating valves, and are all electrically connected to the signal output end of the control device 14; the first pressure detection The signal output ends of the device 2, the second pressure detection device 4, the third pressure detection device 6, and the liquid level detection device are all electrically connected to the signal input end of the control device 14; the main pump 5 can be started by the control device 14, or manually start up.

[0081] 1), the control device 14 closes the pump inlet regulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com