Vertical multi-stage centrifugal pump shaped by stamping and welding

A stamping welding and centrifugal pump technology, applied in the field of centrifugal pumps, can solve the problems of low operating efficiency, high cost, and bulky products, and achieve the effects of convenient assembly and maintenance, extended service life, and light overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

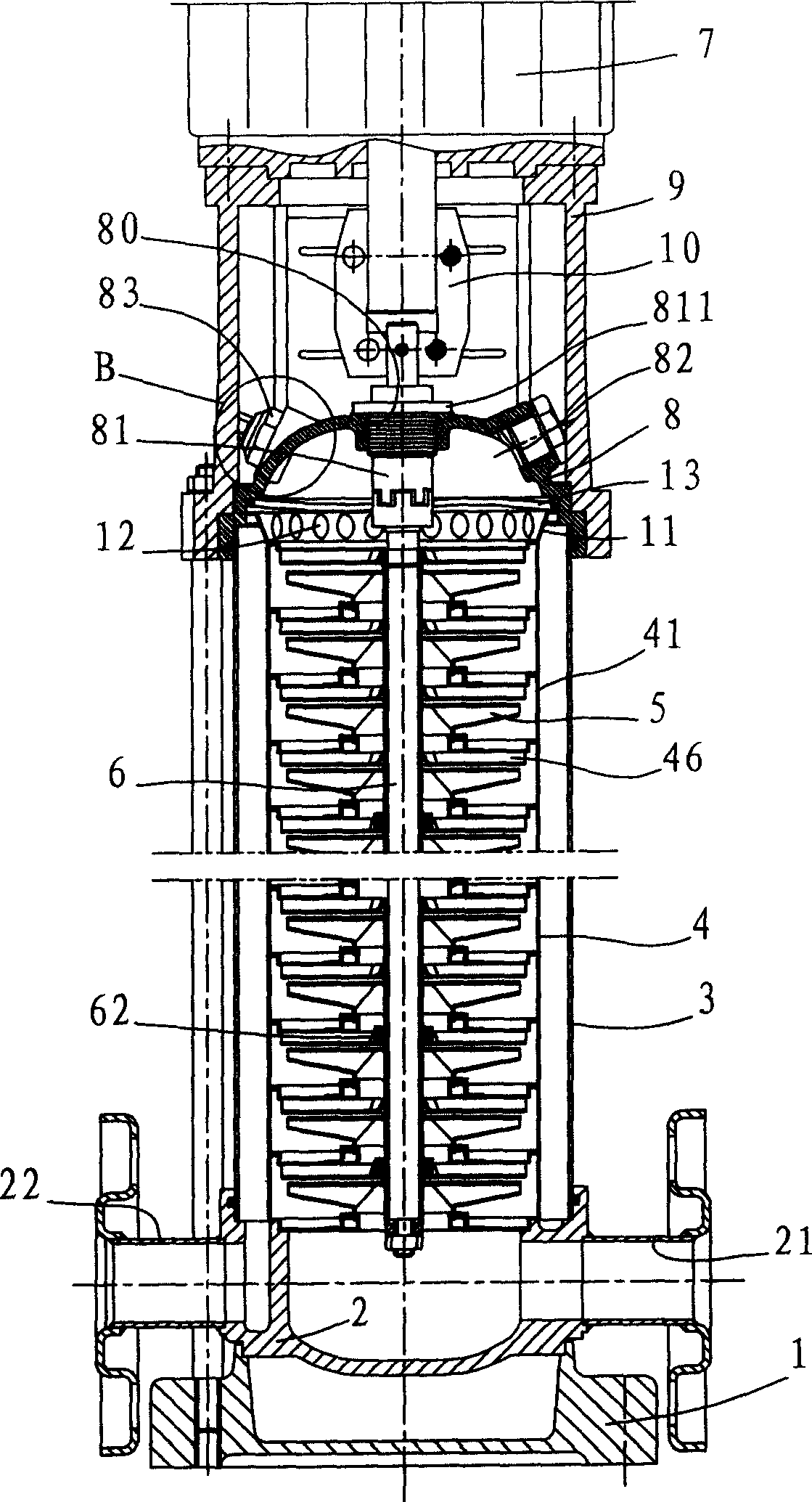

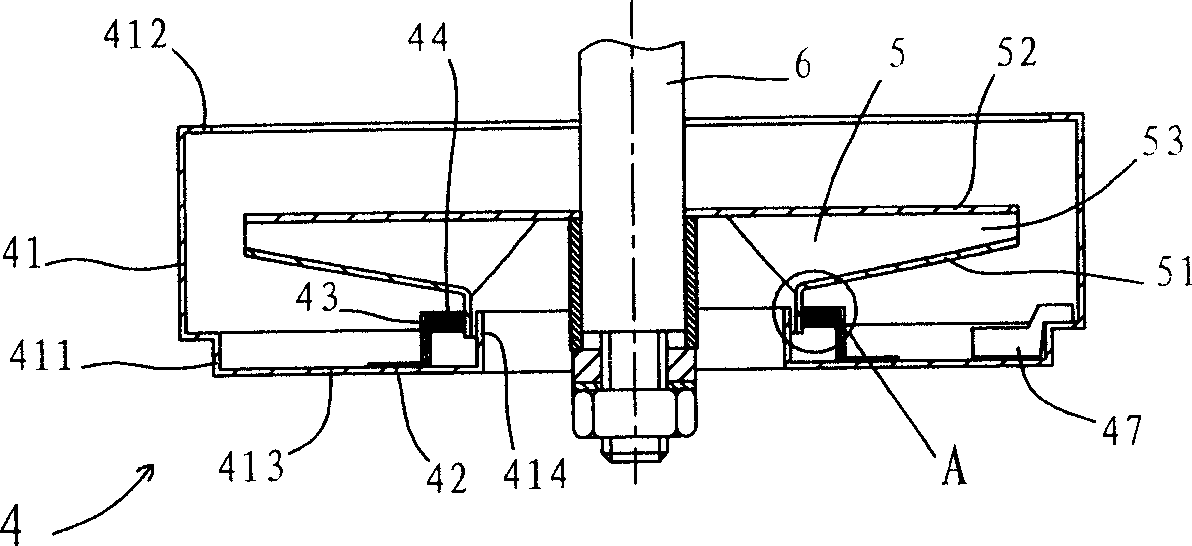

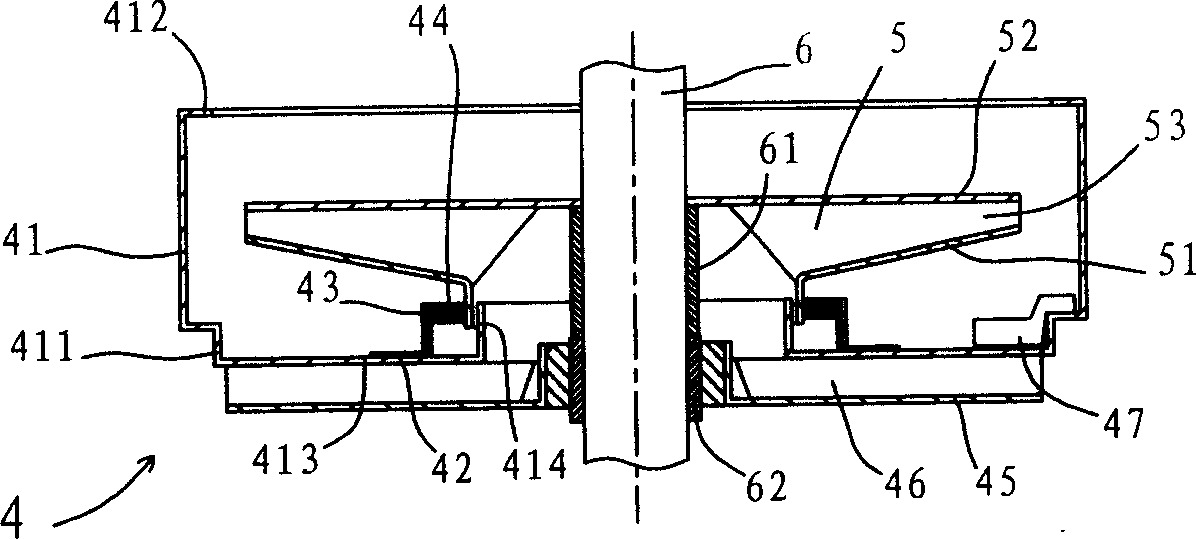

[0036] see figure 1 According to the stamping and welding forming vertical multistage centrifugal pump provided by the present invention, it includes a base 1, a bottom cylinder 2 and an outer cylinder shell 3 installed on the bottom cylinder 2, and the bottom cylinder 2 is provided with a water inlet pipe 21 and A water outlet pipe 22; the outer shell 3 is provided with a multi-stage flow guide part 4 and an impeller 5, and the multi-stage impeller 5 is sequentially installed on the pump shaft 6, and is respectively located in the flow guide part 4, the The guide member 4 includes guide vanes 46, the pump shaft 6 and the impeller 5 are driven to rotate by a motor 7; The upper end of the connecting plate 9 and the lower end of the connecting plate 9 are connected with the base 1 by long bolts.

[0037] Such as figure 1 As shown in , the middle part of the rear cover 8 has a screw hole 80, a mechanical seal 81 passes through the screw hole 80 and is sleeved on the pump shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com