Sectional type multi-stage centrifugal pump and adjustable guide vane devices thereof

A guide vane device and centrifugal pump technology, applied to pump devices, components of pumping devices for elastic fluids, non-volume pumps, etc., can solve the problems of reduced efficiency and low efficiency, and achieve energy saving and improvement Hydraulic efficiency, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

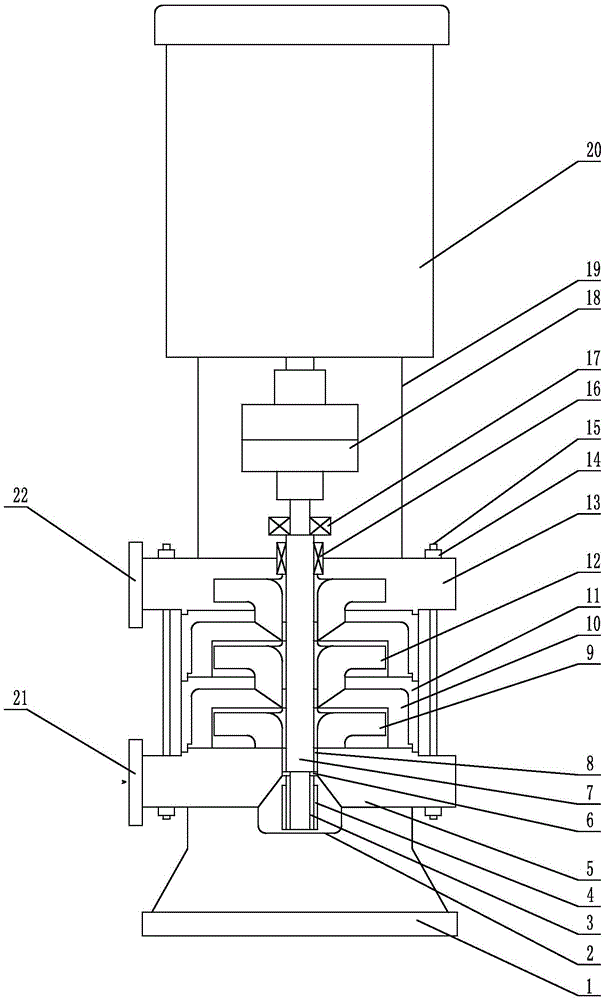

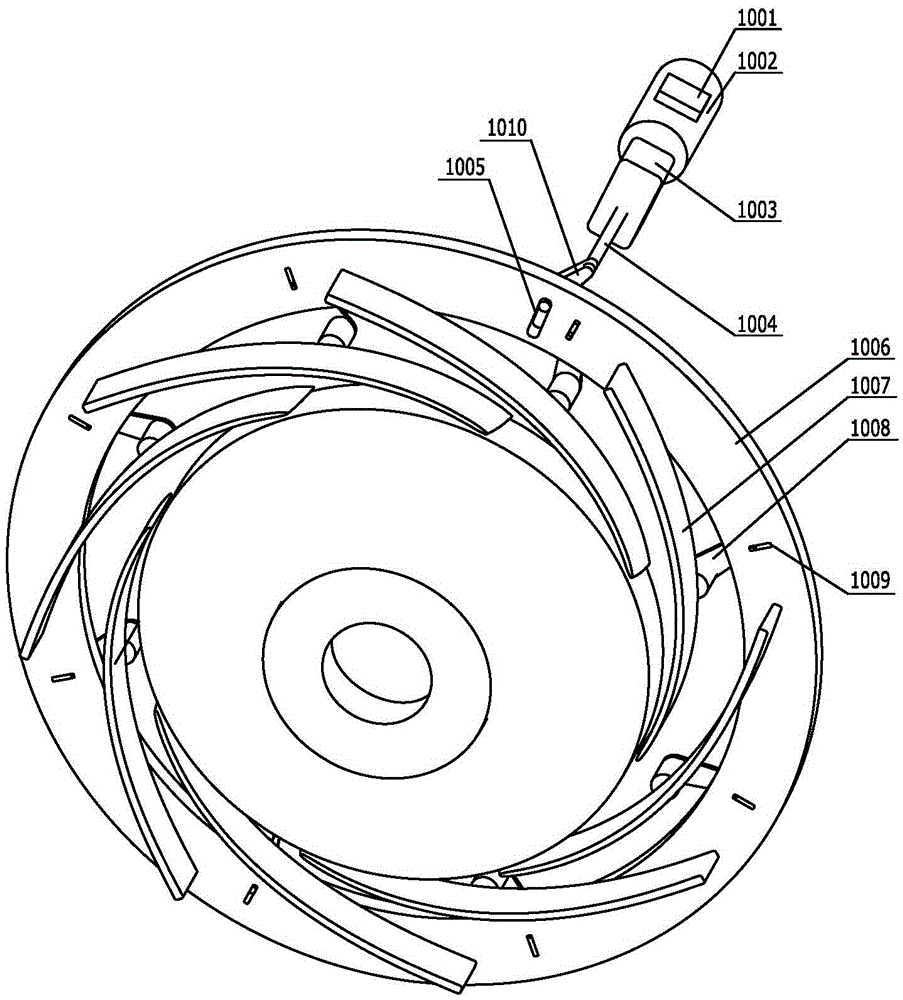

[0052] Such as figure 1 As shown, the segmental multistage centrifugal pump of the present invention specifically includes: base 1, bearing housing 2, bushing 3, sliding bearing 4, water inlet section 5, retaining ring 6, pump shaft 7, impeller spacer ring 8, first Stage impeller 9, adjustable guide vane device 10, middle section 11, secondary impeller 12, water outlet section 13, mechanical seal 16, rolling bearing 17, coupling 18, motor bracket 19 and motor 20, wherein the water outlet section 13 passes bolts 15 nuts 14 is connected with the motor bracket 19, and the water outlet section 13 and the pump shaft 7 are sealed by a mechanical seal 16; the flow channel of the liquid in the water inlet section 5 is the flow channel, and the mouth of the flow channel is the suction po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com