Hydraulic design method for efficient and large-flow vortex pump quasi-annulus pumping chamber

A technology of annular pressurized water chamber and hydraulic design, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve problems that do not involve the improvement of the structure and structural form of swirl pump pressurized water chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

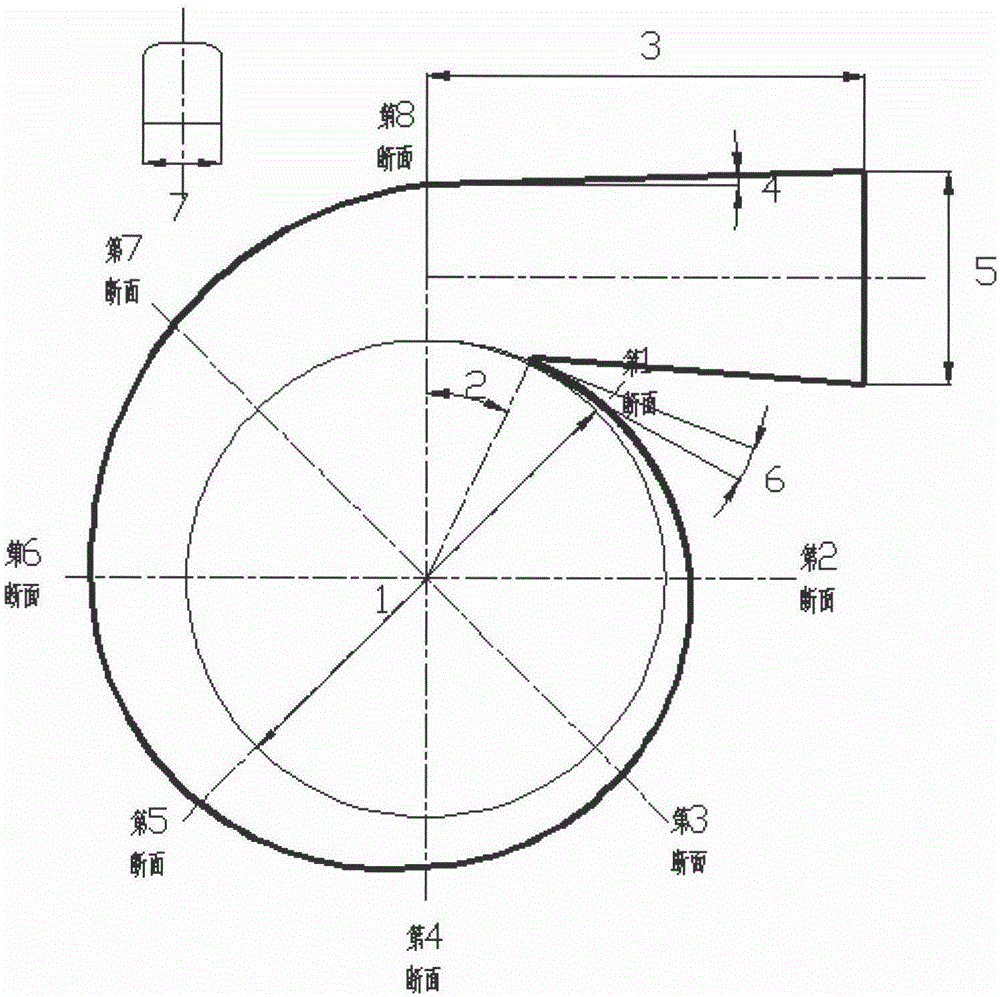

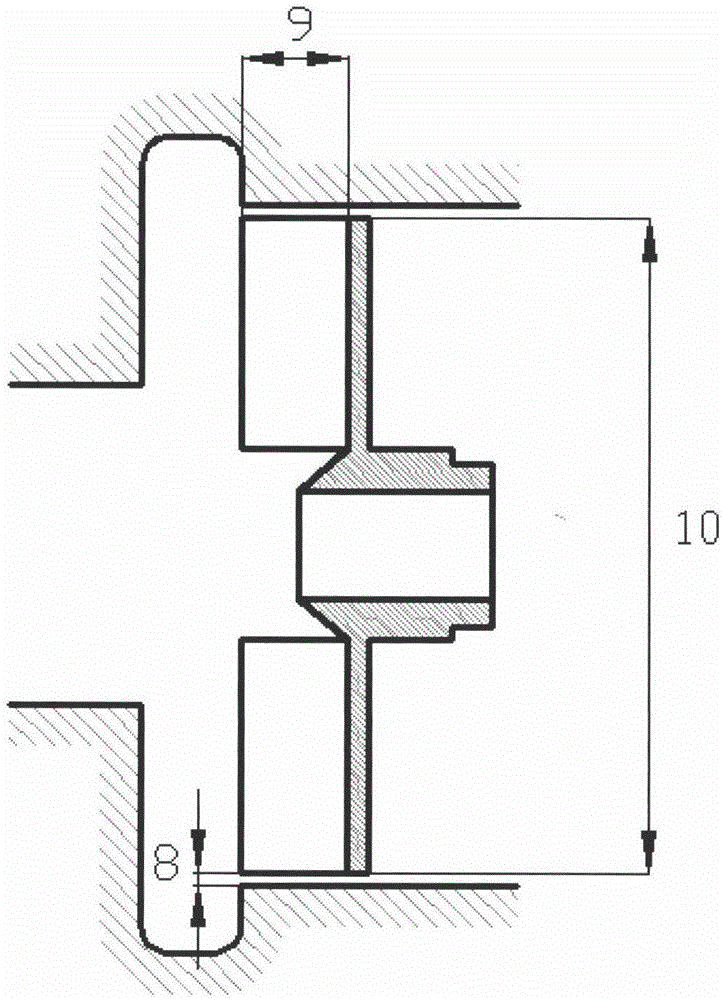

[0071] figure 1 with figure 2 Together determine the shape of the pressurized water chamber of the swirl pump. It can improve the flow condition in the pump, improve the passability of the impurity-containing liquid in the pressure water chamber of the swirl pump and the hydraulic efficiency of the swirl pump. The section of the pressurized water chamber of the present invention is rectangular, and the two corners are transitioned with rounded corners, which is convenient for casting and processing. The arrangement of the diffuser tubes is tangential arrangement, cut at the eighth section. D. d The outlet diameter of the diffuser should be a standard diameter, which is convenient for matching with the existing flange. Satisfy D d When the diameter is the standard and the flow velocity of the medium in the diffusion tube is within the economic flow velocity range, L should be as small as possible to reduce the overall size of the swirl pump overall device. The present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com