Air inlet channel of air-breathing type pulse detonation engine

A technology of pulse detonation and air inlet, which is applied in the direction of ramjet engines, combined engines, mechanical equipment, etc., can solve the problems of forward flow resistance and one-way control ability, large windward area, performance loss, etc. problem, to achieve the effect of small forward flow resistance, increase operating frequency, and increase engine thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

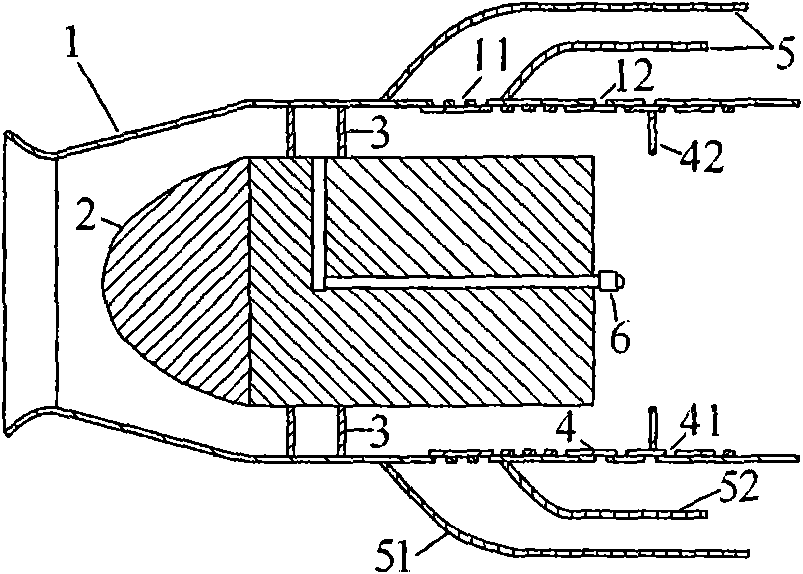

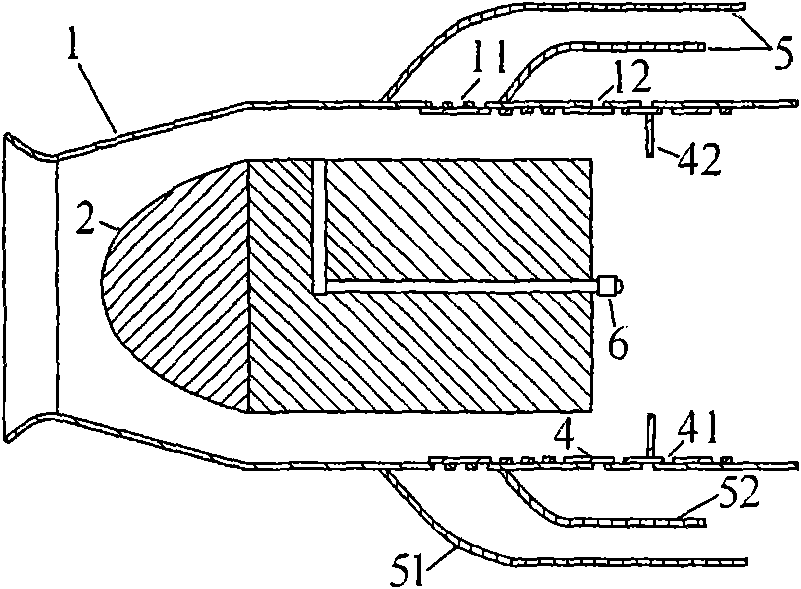

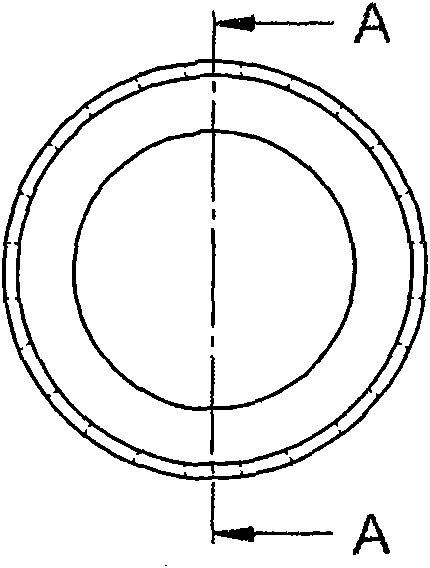

[0035] The air inlet of the pulse detonation engine of the present invention comprises an air inlet shell 1, a central body 2, a bracket 3, an actuating mechanism 4, an air release pipe 5 and a nozzle 6, and the inlet opening is forward, as shown in FIG. 1 . Two or more brackets 3 can be evenly distributed along the circumferential direction, as shown in Figure 1(a). The actuating mechanism 4 is driven by an electric actuator or a hydraulic mechanism, and can be made into an integral axially forward and backward actuating structure, as shown in FIG. 2 , or can be composed of multiple actuating units, as shown in FIG. 3 . The air intake housing is provided with multiple rows of incoming flow vent slots 11 and reverse flow vent slots 12 from the front to the rear at two-fifths to four-fifths, and is used in conjunction with the vent slots 41 on the actuator 4. . The incoming air discharge hole groove 11 and the reverse flow air release hole groove 12 are respectively distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com