Straight pipe type silencer

A muffler, straight pipe technology, applied in the direction of muffler, machine/engine, engine components, etc., can solve the problems of poor noise reduction effect, high cost of use, complex structure, etc., to achieve good noise reduction effect and airflow noise Weaken and reduce the effect of noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

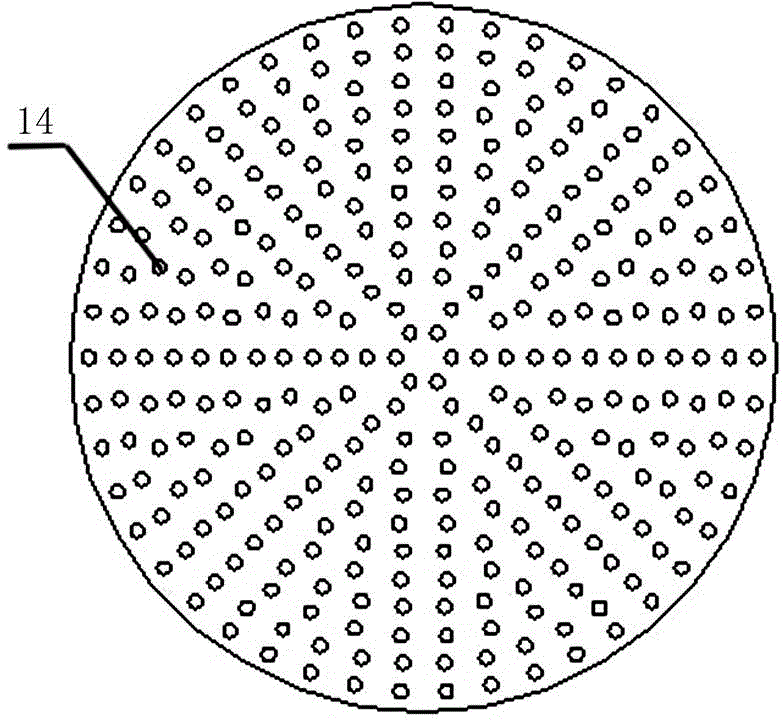

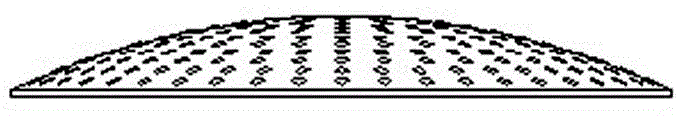

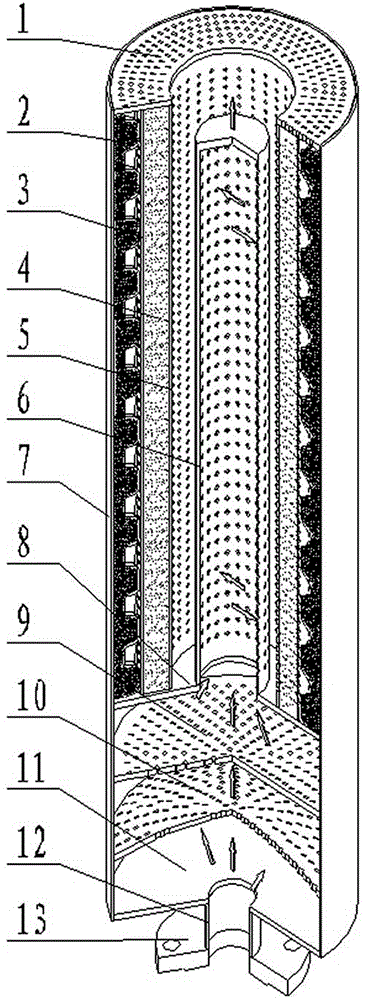

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing: figure 1 As shown, it includes an outer cylinder, the air inlet end of the outer cylinder is provided with an air inlet end plate 11, the air outlet end is provided with a damping orifice plate 1, and the middle part is provided with a baffle plate 8 with a through hole to divide the inside of the outer cylinder into an upper inner cavity and the lower inner cavity, the lower inner cavity is provided with a spherical damping orifice plate 10 and a plane damping orifice plate 9 in sequence along the gas flow direction, and the baffle plate 8 is coaxially welded with an integrally located in the upper cavity An air guide tube 6, one end of the air guide tube 6 communicates with the lower inner cavity through the through hole on the baffle plate 8, the other end is closed, and a group of sound-absorbing holes are opened on the side wall of the air guide tube, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com