Cold trap

A cold trap and cold plate technology, which is applied in the directions of condensation traps/cold partitions, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of reduced exhaust flow path conductivity and reduced exhaust flow path cross-sectional area. , to achieve the effect of increasing the exhaust velocity and suppressing the decrease of the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the description, the same reference numerals are assigned to the same elements, and overlapping descriptions are appropriately omitted. In addition, the structures described below are examples and do not limit the scope of the present invention in any way.

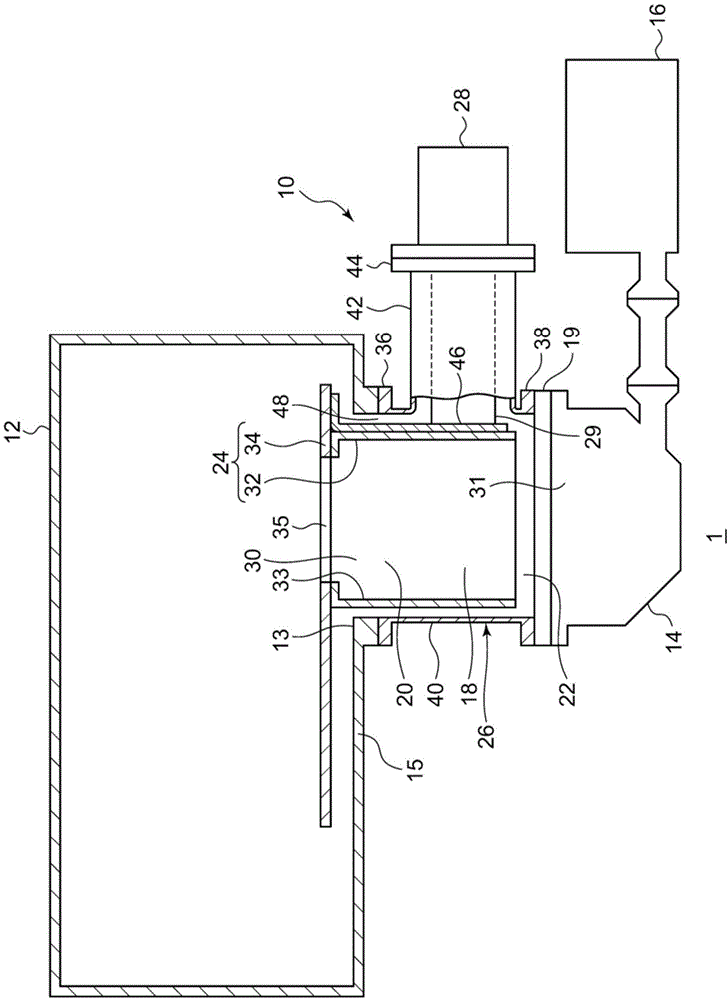

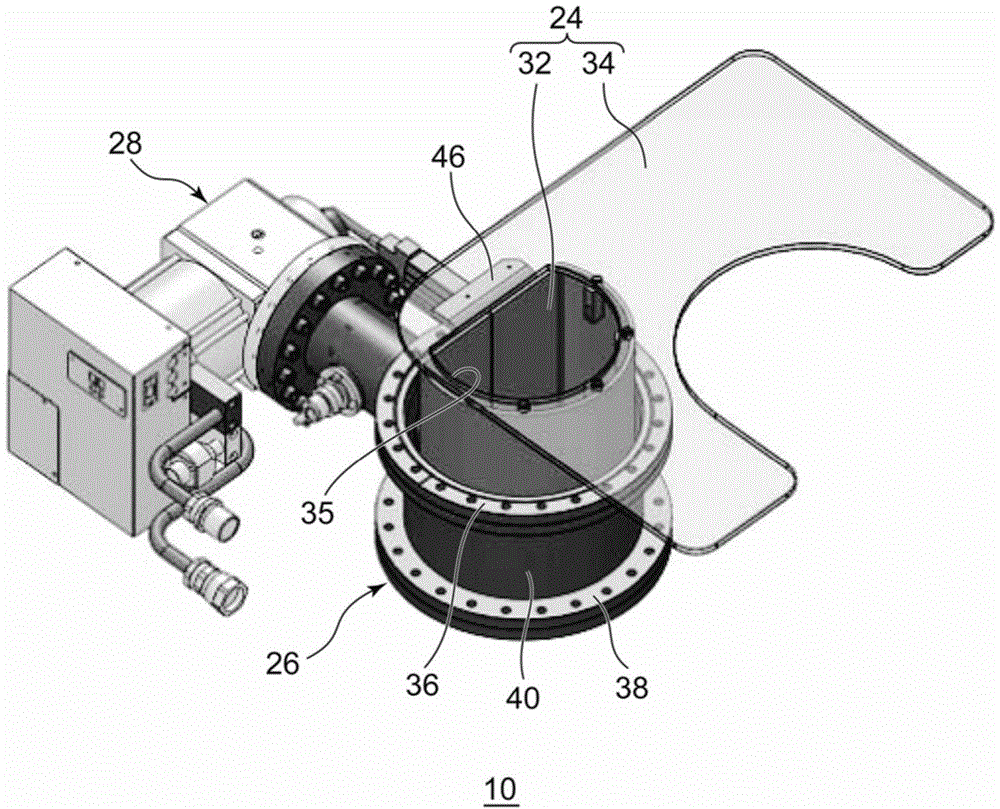

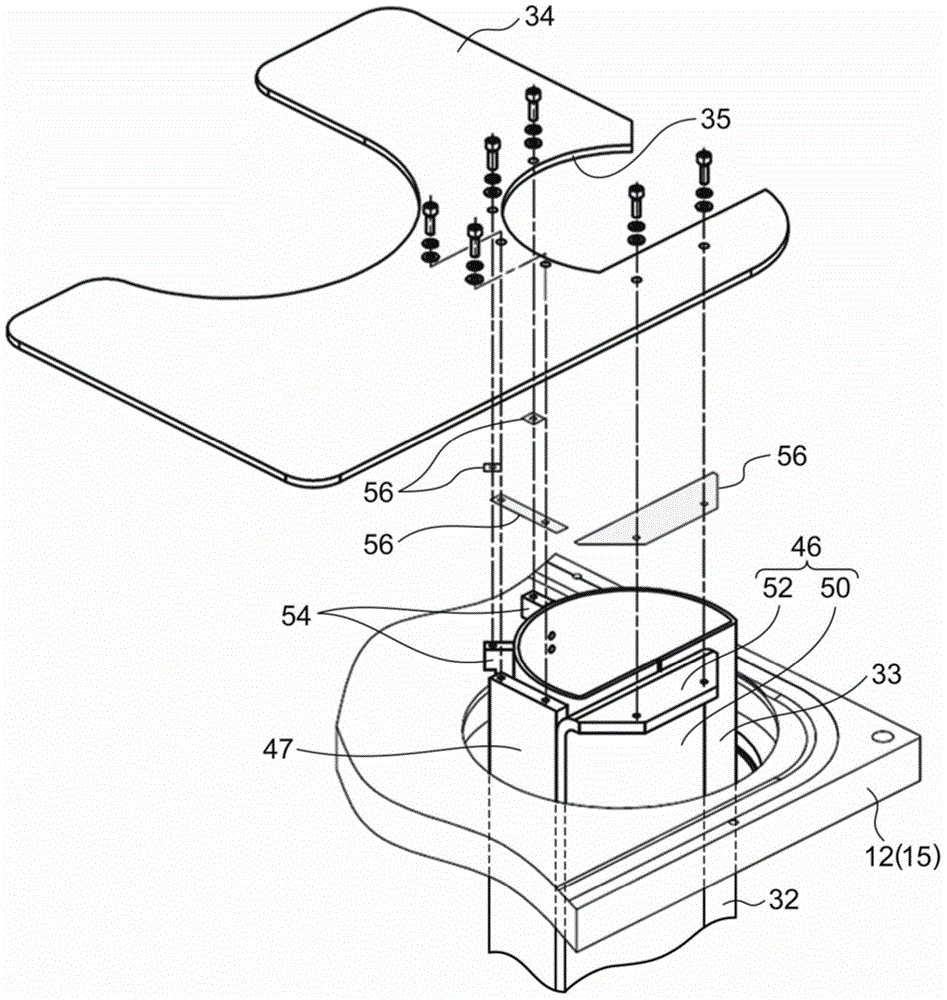

[0017] figure 1 It is a cross-sectional view schematically showing the vacuum evacuation system 1 according to one embodiment of the present invention. figure 2 It is a perspective view schematically showing the cold trap 10 according to one embodiment of the present invention. image 3 It is an assembly diagram schematically showing a part of the cold trap 10 according to one embodiment of the present invention.

[0018] Such as figure 1 As shown, the vacuum evacuation system 1 includes a cold trap 10 and a main vacuum pump (such as a turbomolecular pump 14 ) for evacuating a volume to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com