A plunger type lubricating grease pump

A lubricating grease and plunger-type technology, which is applied in the direction of lubricating pumps, engine lubrication, engine components, etc., can solve the problems of manual operation safety hazards, incomplete free flow, and affecting project progress, so as to improve work efficiency and save manpower Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

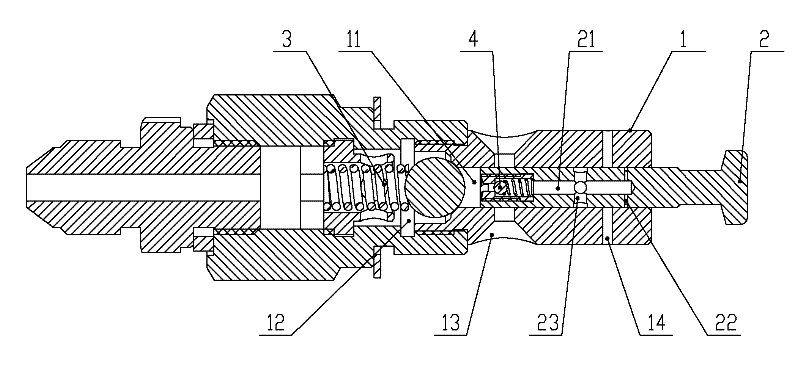

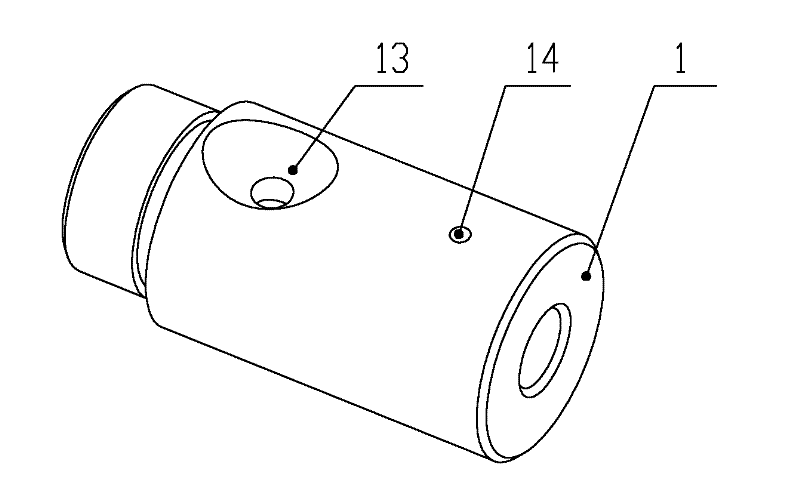

[0029] Please refer to figure 1 with figure 2 The plunger type lubricating grease pump of the present embodiment includes a pump body 1 and a plunger 2. The front end and the middle part of the pump body 1 are respectively provided with an oil outlet 12 and an oil suction hole 13, and the oil outlet 12 and the oil suction hole 13 are used for forming In the pump chamber 11 containing lubricating grease, the plunger 2 is installed at the rear end of the pump body 1. The oil pump end of the plunger 2 is placed in the pump chamber 11, and the other end protrudes out of the pump body 1 for operation, and is operated under the action of external force. reciprocating motion.

[0030] The pump body 1 rear end is also provided with a pump body exhaust hole 14, which can be arranged on the side wall of the pump body 1 rear end, communicates with the inside and outside of the pump body 1, and is located at the opening outside the pump body 1 Together with the oil suction hole 13, it ...

no. 2 example

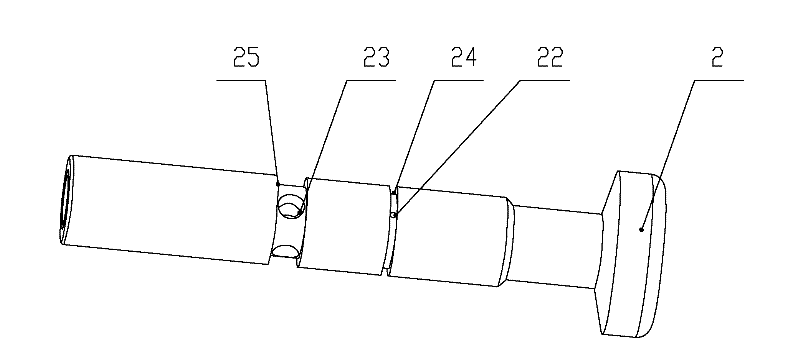

[0038] Please refer to figure 1 with image 3 , the plunger 2 of the plunger type lubricating grease pump of the present embodiment is also provided with a second plunger vent 23, and the second plunger vent 23 is located between the check valve 4 and the first plunger vent 22. Between, when the pump oil end is in the oil suction position and the oil suction port 13 is opened, the second plunger vent hole 23 communicates the plunger chamber 21 with the pump body vent hole 14, and there is a certain pressure in the plunger chamber 21 at this time. The gas will expand, and part of the gas or lubricating grease in the plunger cavity 21 will pass through the second plunger vent hole 23 and the pump body in sequence during the process of communicating the second plunger vent hole 23 with the pump body vent hole 14. The body vent 14 vents outward to the fuel tank.

[0039] In this embodiment, only one set of pump body exhaust holes 14 on the pump body 1 can be provided, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com