T-shaped impedance micropore multi-combination exhaust silencing device

A technology of silencer and microporous, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc., can solve the problems of flocculation and large influence on the surrounding environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

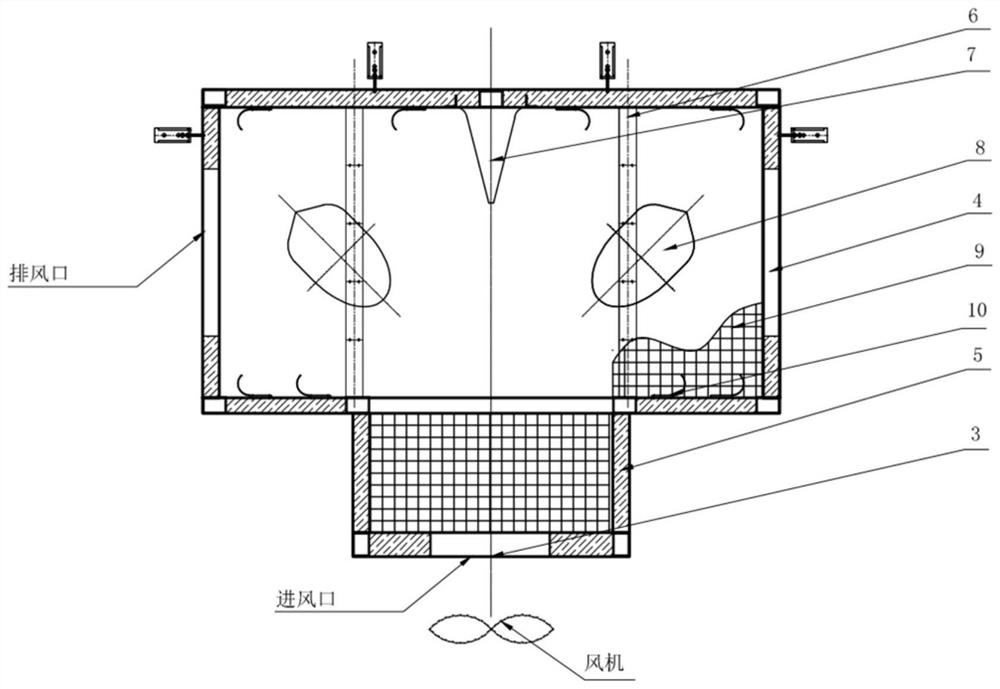

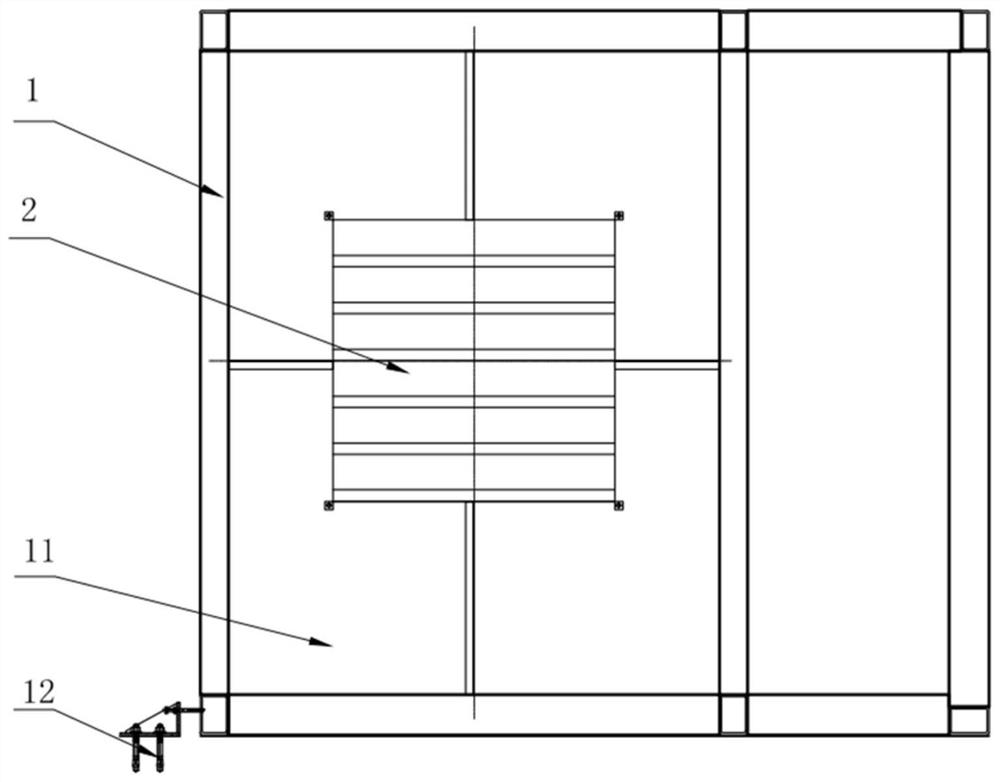

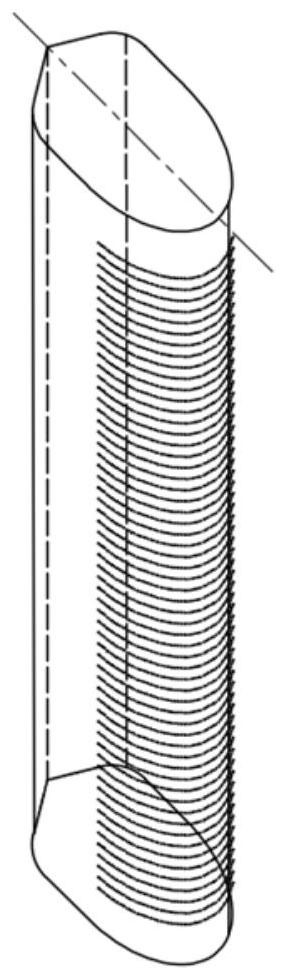

[0023] Such as figure 1 , 2 Shown: a T-type impedance microporous multi-combination air exhaust and silencer device of the present invention includes a metal frame 1, and the strength and rigidity of the device can be guaranteed by adopting a metal frame structure; the surface of the metal frame is made of stainless steel skin 11 with imported structural glue Tightly wrap the gap to form the first sealing layer, enhance the strength, brightness and service life of the device, and at the same time enhance the function of wind and rain protection; the exhaust and silencer device is in the shape of a "T" as a whole, and the end of the "T" shape is the air inlet 3. The left and right ends are air outlets 4. When in use, the air inlet 1 is flexibly connected to the fan outlet (that is, the air inlet corresponds to the fan outlet, and can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com