Assembly for cooking with a safety device

a safety device and cooking technology, applied in the field of assembly for cooking, can solve the problems of substandard cooking fume filtering performance and inefficient drawing of cooking fumes, and achieve the effects of preventing scattering, enhancing the rotation speed of the air pump, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Wherever possible, the same reference numbers are used in the drawings and the description to refer to the same or like parts.

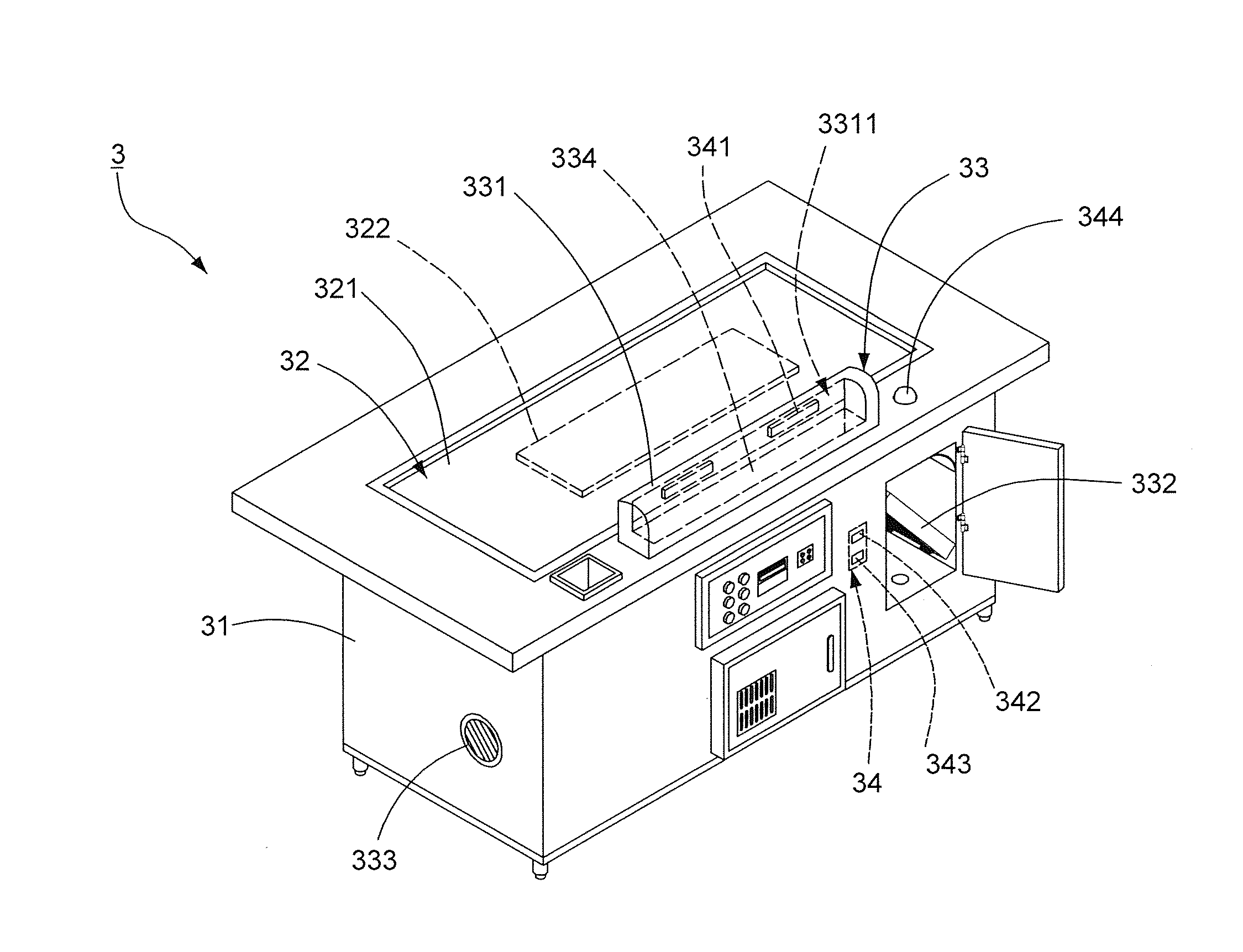

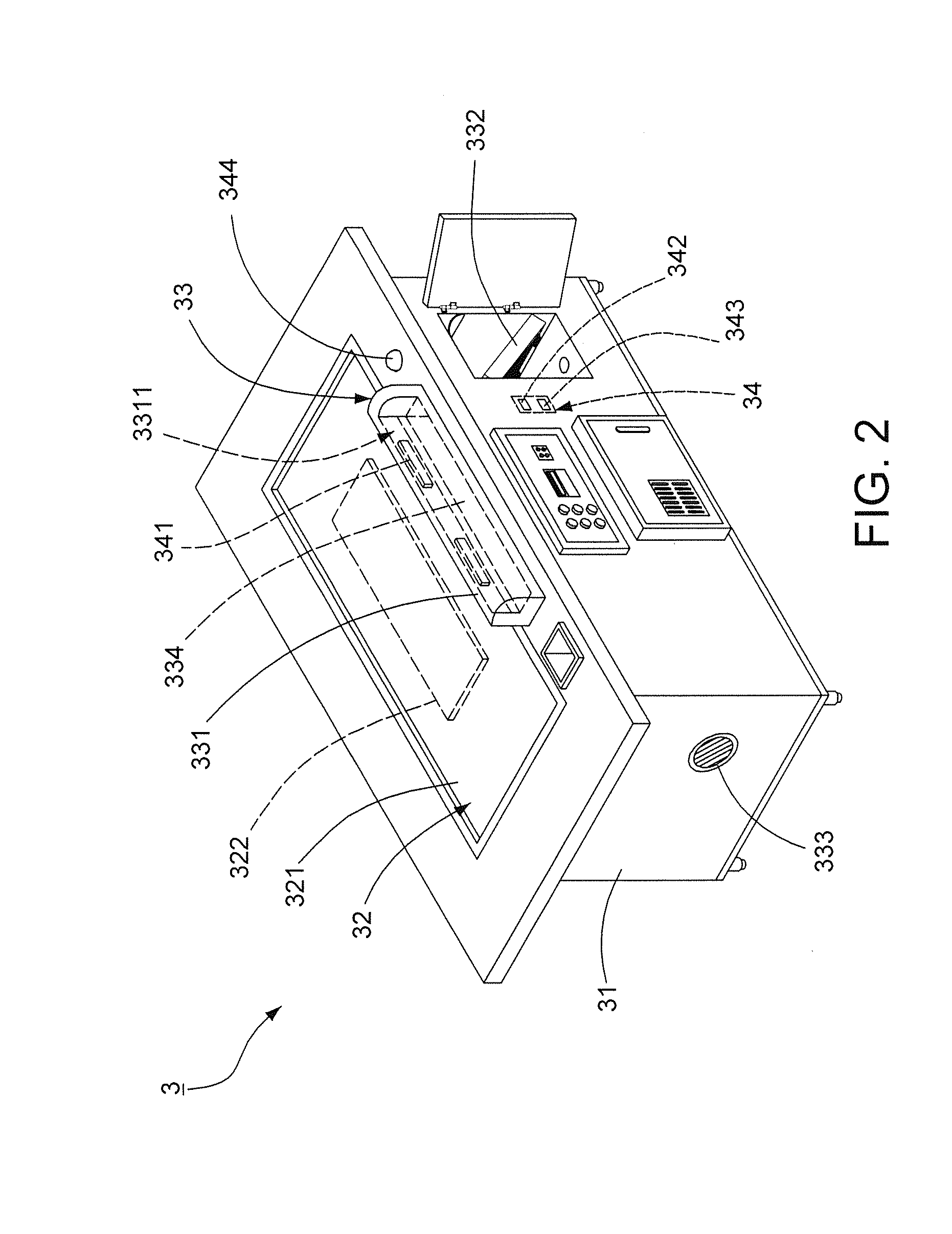

[0022]Referring to FIG. 2, a first preferred embodiment of the present invention is shown. An assembly 3 for cooking with a safety device comprises a platform 31, a cooking device 32 disposed on the platform 31 for cooking food, an air guider 33 disposed on the platform 31 for inhaling cooking fumes during cooking, and a safety device 34 disposed on the platform 31. Wherein, the cooking device 32 has a cooking plane 321 disposed on the platform 31, and a heater 322 that is able to heat the cooking plane 321. As to the air guider 33, it has a housing 331 disposed on the platform 31 and located beside the cooking plane 321, a filter 332 disposed in the platform 31, an air pump 333 disposed on the platform 31, and an air channel 334 disposed to communicate the housing 331, the filter 332, and the air pump 333 with each other.

[0023]Especially, referring to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com