Novel rapid mounting pneumatic vibrator

A pneumatic vibrator, fast technology, applied in the direction of vibrating fluid, ceramic molding machine, manufacturing tools, etc., can solve the problems of short service life, troublesome installation, small vibration force, etc., to reduce product weight, fast and convenient installation , Improve the effect of exciting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

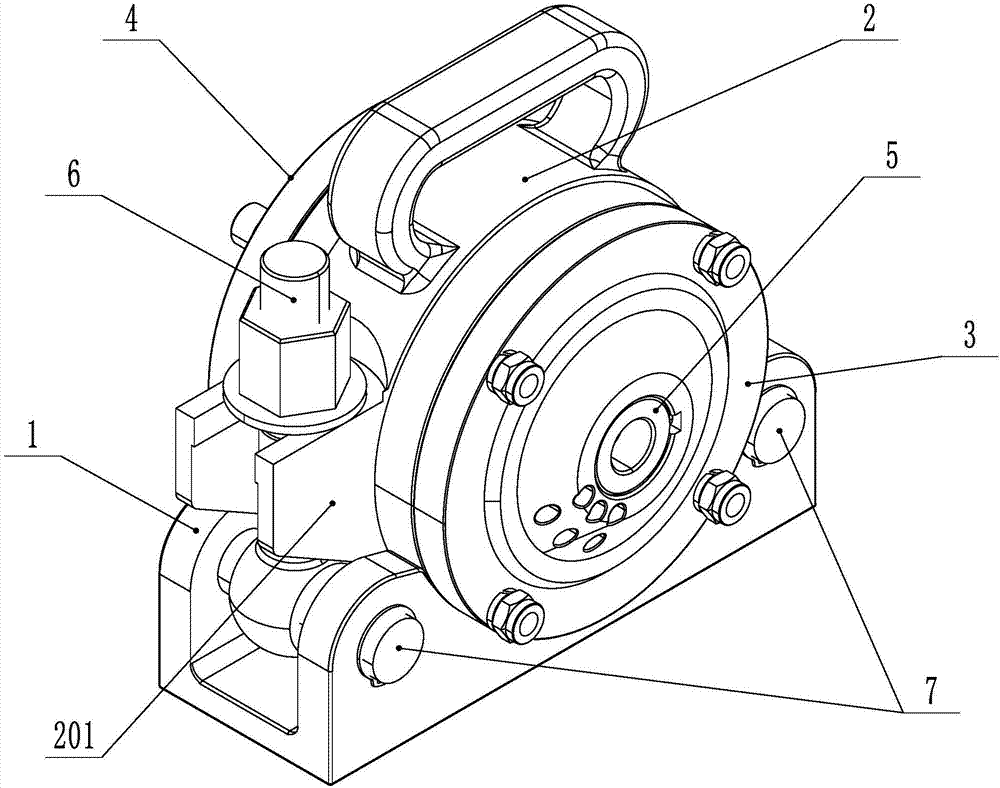

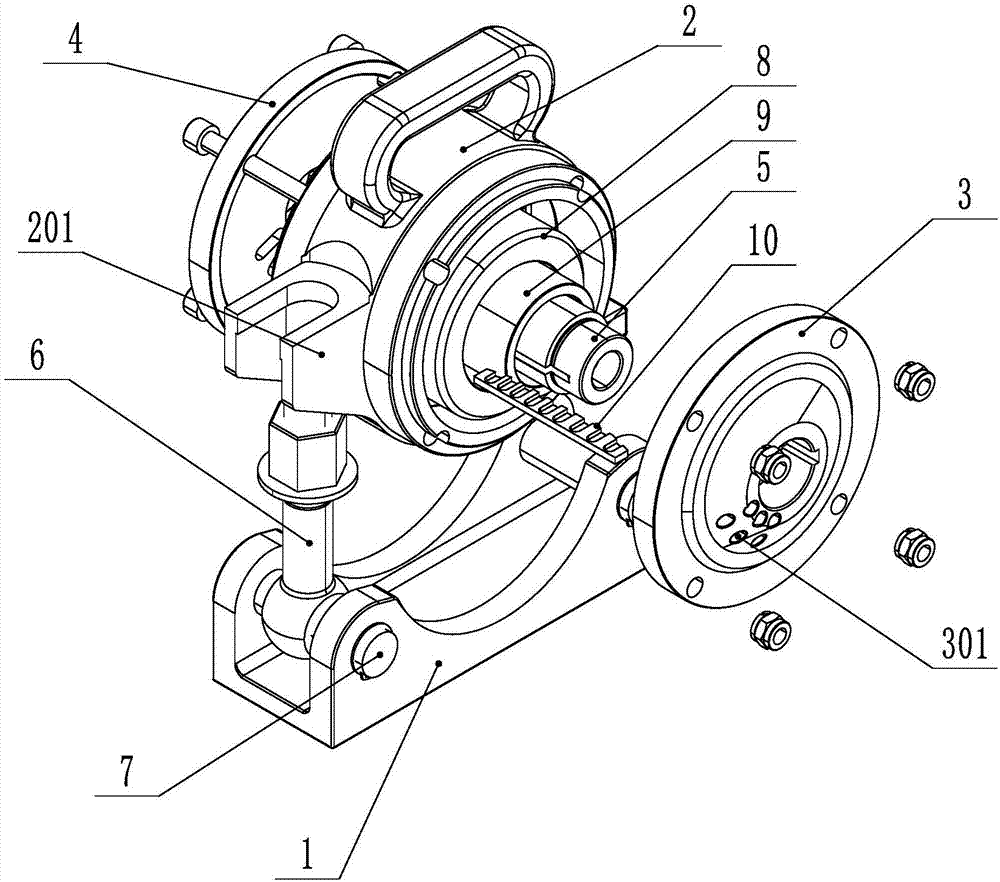

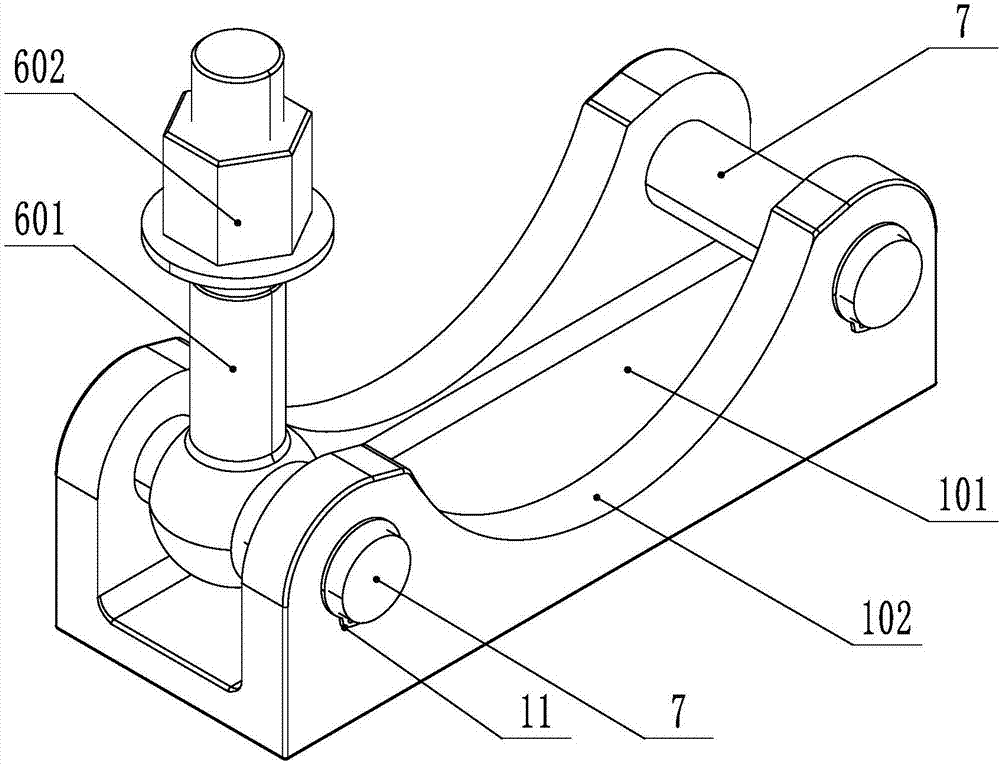

[0037] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0038] Such as Figure 1-8 As shown, a new type of quick-installation pneumatic vibrator includes a base 1 connected to the mold, a machine base 2 arranged on the base 1, a front end cover 3 and a rear end cover 4 respectively arranged on the front and rear sides of the machine base 2, The front and rear ends are connected with the front end cover 3 and the rear end cover 4 respectively, the central axis 5, the eccentric rotation inner casing 9 arranged outside the central axis 5, the eccentric rotation outer casing arranged between the eccentric rotation inner casing 9 and the machine base 2 Pipe 8, central shaft 5 center and outer side are provided with air chamber 501 and chute 503 respectively, central shaft 5 is located on the side of front end cover 3 and is provided with the connection port 504 that air chamber 501 is connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com