High-precision flared fitting forming tool

A technology for forming tooling and bell mouth, applied in vehicle parts, transportation and packaging, etc., can solve the problems of uncontrollable length of pipe fittings, complicated processing procedures, slow processing speed, etc., to improve product quality, ensure exhaust performance, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

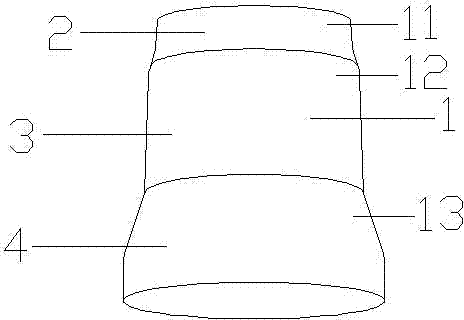

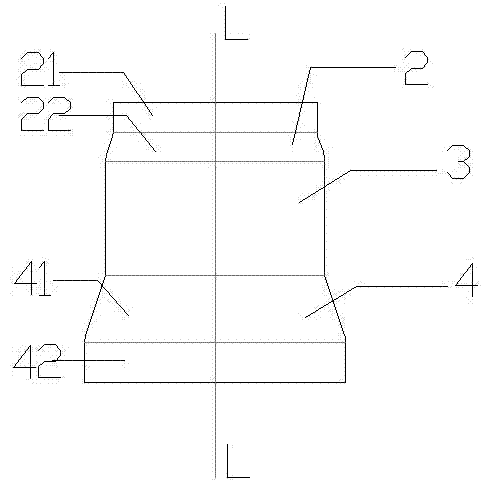

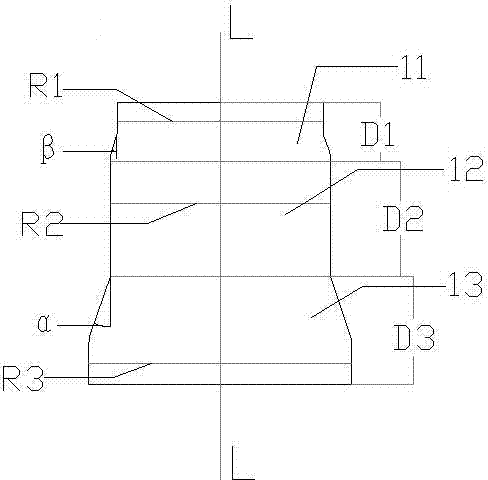

[0012] A high-precision bell-mouth pipe fitting forming tooling is characterized in that it includes a pipe body 1, which is divided into a pipe body upper end 11, a pipe body middle end 12 and a pipe body lower end 13, the pipe body upper end 11 is a necking end 2, and the pipe body The middle end 12 is a transition section 3, and the lower end 13 of the pipe body is a flaring end 4. The necking end 2 includes a hollow cylindrical necking 21 and a hollow conical necking arc 22, and the flared end 4 includes Hollow cylindrical flaring 41 and hollow conical flaring arc 42; the length of the upper end 11 of the pipe body is D1, the length of the middle end 12 of the pipe body is D2, the length of the lower end 13 of the pipe body is D3, and the length of the upper end of the pipe body 11 The ratio of the length, the length of the middle end 12 of the pipe body and the length of the lower end 13 of the pipe body is 1:1.97:1.82, the outer diameter of the upper end 11 of the pipe bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com