Multifunctional polyurethane reaction kettle condensation recovery device

A technology of condensation recovery and reactor, which is applied in the fields of dispersed particle filtration, chemical/physical/physicochemical processes, adsorption water/sewage treatment, etc. It can solve the problems of inconvenient support adjustment, inability to detect collection liquid level, and affect recovery efficiency. To achieve the effect of improving the exhaust efficiency, ensuring the exhaust effect and avoiding the influence of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

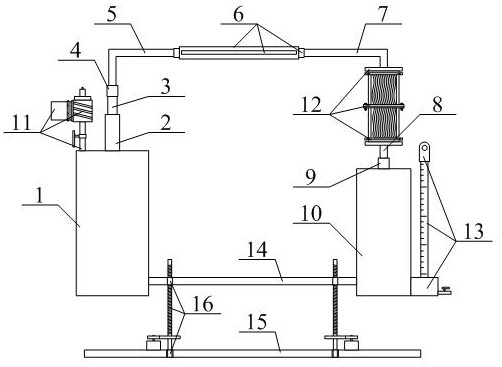

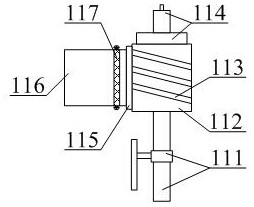

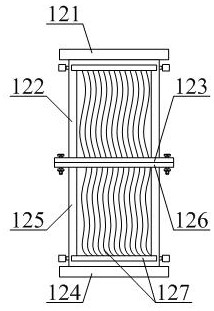

[0034]Below in conjunction with accompanying drawing, the present invention is described in detail, as shown in accompanying drawing 1 and accompanying drawing 2, a kind of multifunctional polyurethane reactor condensation recovery device comprises reactor body 1, gas phase outlet pipe 2, alcohol-water separator 3, connects Tube head 4, air guide pipe 5, condenser 6, condensate water pipe 7, guide pipe 8, butt joint 9, buffer tank 10, open and close gas phase discharge antifouling treatment box structure 11, split liquid antifouling adsorption core Structure 12, liquid level buffer visual observation tube structure 13, lifting seat 14, support base 15 and electric height adjustment rotating rod structure 16, the upper outlet of the reaction kettle body 1 is threadedly connected with the gas phase outlet pipe 2; The upper end of the gas phase outlet pipe 2 is threaded with an alcohol-water separator 3; the upper end of the alcohol-water separator 3 is threaded with a connecting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com