Production process of supramolecular acidification system prepared from glyphosate wastewater

A technology for glyphosate wastewater and production process, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems that it is difficult to completely recover glyphosate, cannot recover glyphosate resources, and has high COD value. To achieve the effect of convenient direct discharge treatment, easy process and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

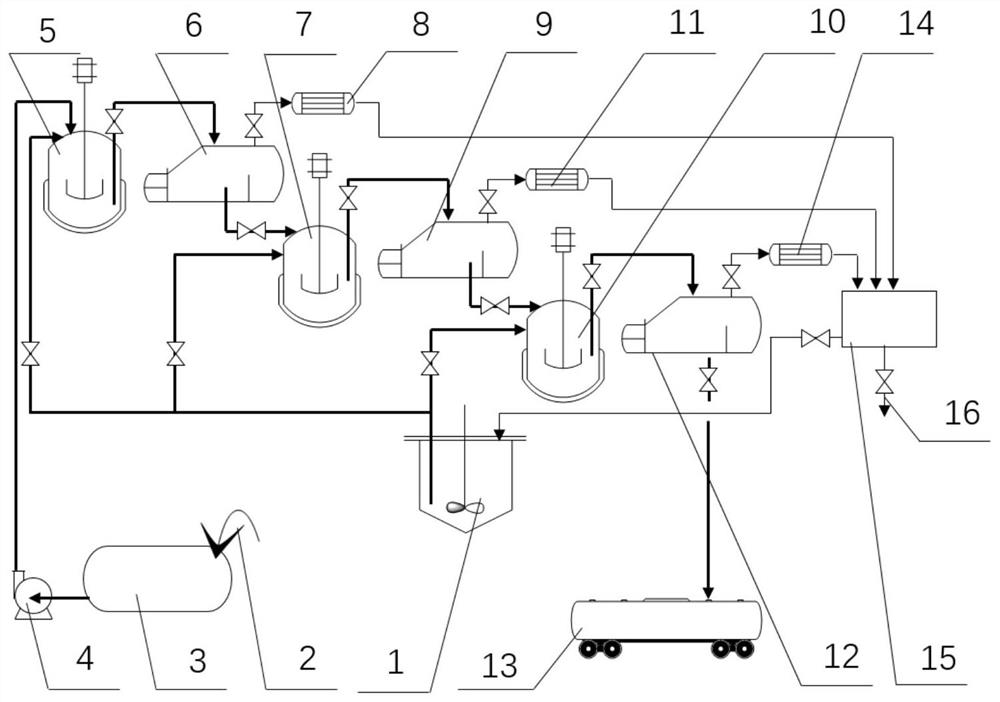

[0056] Example 1 Production process system for preparing supramolecular acidification system with glyphosate wastewater

[0057] Please combine figure 1 , this embodiment provides a production process system for preparing a supramolecular acidification system with glyphosate wastewater, including a liquid distribution tank 1, a waste liquid tank 3, a liquid lifting pump 4, a primary reaction kettle 5, a primary evaporator 6, Secondary reactor 7, primary condenser 8, secondary evaporator 9, third-stage reactor 10, secondary condenser 11, third-stage evaporator 12, tank car 13, third-stage condenser 14, condensate tank 15 And drain condensate line 16. Wherein, the waste liquid tank 3 is used to store the glyphosate wastewater 2 . The liquid mixing tank 1 is used to configure the aqueous solution of hydroxypropyl-β-cyclodextrin. The primary reaction kettle 5 is respectively connected to the waste liquid tank 3 and the liquid distribution tank 1 through pipelines, and is used f...

Embodiment 2

[0061] The present embodiment provides a kind of production technology that prepares supramolecular acidification system with glyphosate waste water, comprises the following steps:

[0062] (1), adopt the production process system of the supramolecular acidification system prepared by glyphosate waste water of embodiment 1, add the clear water of 180kg hydroxypropyl-beta-cyclodextrin and 200kg in liquid mixing tank 1, stir and heat up 60 ℃, fully dissolved, and configure the aqueous solution of hydroxypropyl-β-cyclodextrin. Put 2000kg of glyphosate waste water (glyphosate content 8000-12000mg / L, total phosphorus 11000-13000mg / L, pH value 8.5) into waste liquid tank 3 through a movable hose for use.

[0063] (2), press the 125kg hydroxypropyl-β-cyclodextrin aqueous solution in the liquid mixing tank 1 into the first-stage reaction kettle 5 through compressed air, and pump all the glyphosate wastewater into the first-stage reaction through the 4 pumps In the kettle 5, a first-s...

Embodiment 3

[0068] The present embodiment provides a kind of production technology that prepares supramolecular acidification system with glyphosate waste water, comprises the following steps:

[0069] (1), adopt the production process system of the supramolecular acidification system prepared by glyphosate waste water of embodiment 1, add the clear water of 180kg hydroxypropyl-beta-cyclodextrin and 200kg in liquid mixing tank 1, fully dissolve, configure Hydroxypropyl-β-cyclodextrin in water. 2000kg of glyphosate waste water (containing diglyphosate, glyphosate content 10000-14000mg / L, total phosphorus 11000-13000mg / L, pH value 8.24) is put into the waste liquid tank 3 for use through a movable hose .

[0070] (2), press the 125kg hydroxypropyl-β-cyclodextrin aqueous solution in the liquid mixing tank 1 into the first-stage reaction kettle 5 through compressed air, and pump all the glyphosate wastewater into the first-stage reaction through the 4 pumps In the kettle 5, a first-stage as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com