Polyethylene bio-carrier, preparation method thereof and application of polyethylene bio-carrier to sewage treatment

A bio-filler and polyethylene technology, which is applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problem of film-hanging speed, film-hanging amount and tightness between film and filler , poor hydrophilic performance and bio-affinity, high polyethylene content, etc., to achieve the effect of shortened process start-up period, low price and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of polyethylene biofiller, comprising the steps of:

[0033] (1) Wash the sugarcane residue in water, soak it in alcohol, rinse it with alcohol, dry it at 105-180°C, and crush it to 80-150 mesh;

[0034] (2) Mix the sugarcane residue obtained in the step (1) with linear low-density polyethylene and 200-325 mesh activated carbon powder, and then die-cast.

[0035] Wherein, the mass ratio of low-density linear polyethylene, sugarcane residue and powdered activated carbon is 70:20:10.

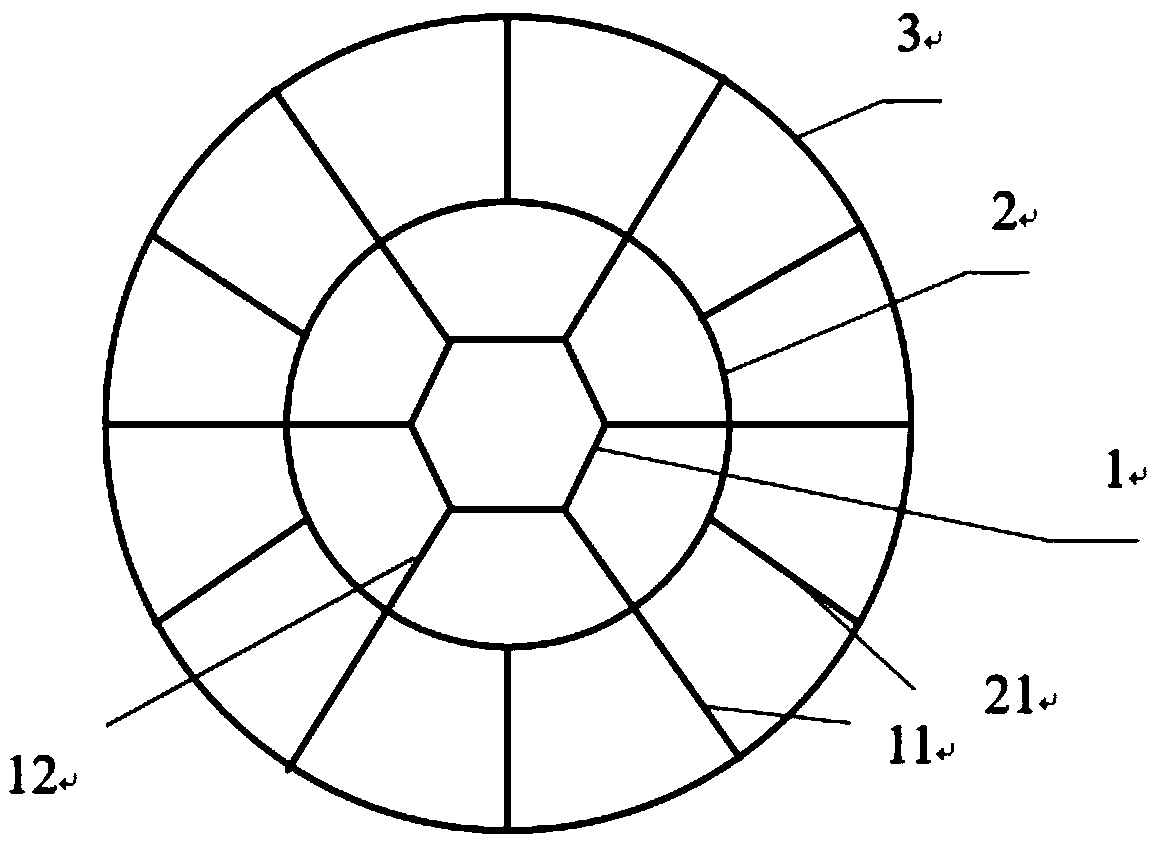

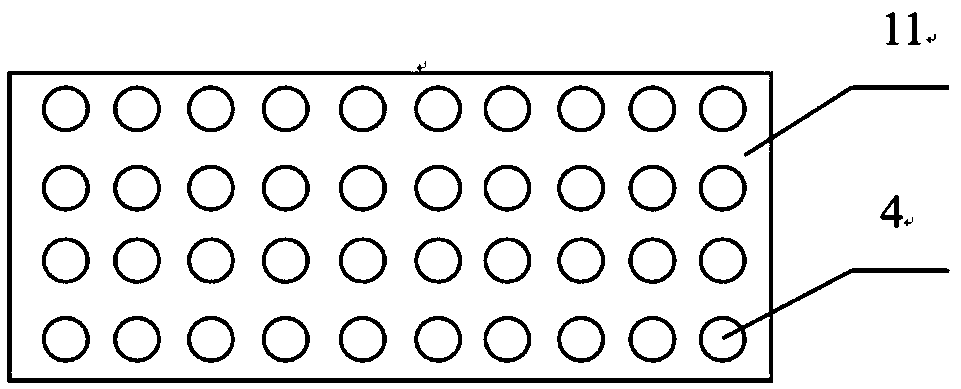

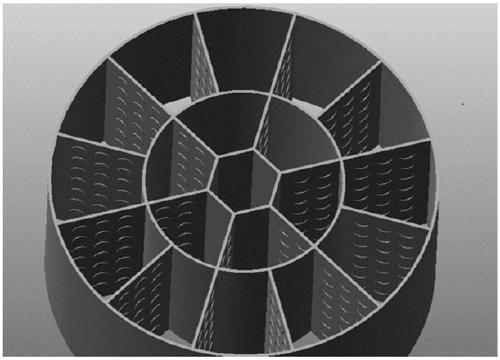

[0036] Such as Figures 1 to 2 As shown, the prepared filler is 14 mm high and 30 mm in diameter, and its main frame includes a polygonal ring 1 (with a side length of 3 mm) arranged in the center and a first circular ring 2 (diameter 15 mm) and a second circular ring 2 (diameter 15 mm) arranged on the periphery of the polygonal ring in turn. Two circular rings 3, each longitudinal edge 11 of the polygonal ring 1 is fixed with a first radial rib 12, and the first radi...

Embodiment 2

[0039] The difference from Example 1 is that the low-density linear polyethylene: sugarcane residue: powdered activated carbon mass ratio is 60: 30: 10, the filler is 5 mm high, the diameter is 10 mm, and the side length of the hexagonal ring is 0.8 mm. The diameter of the ring 2 is 5 mm, the diameter of the groove 4 is 0.5 mm, the depth is 0.3 mm, and the distance between adjacent grooves is 0.8 mm.

Embodiment 3

[0041] The difference from Example 1 is that the low-density linear polyethylene: sugarcane residue: powdered activated carbon mass ratio is 65: 20: 15, the filler is 8 mm high, and the diameter is 20 mm. The side length of the hexagonal ring is 2 mm. The first circle The diameter of the ring 2 is 10 mm, the diameter of the groove 4 is 1 mm, the depth is 0.4 mm, and the distance between adjacent grooves is 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com