Safe automatic exhaust manifold welding device and working method thereof

An exhaust manifold, automatic welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of exhaust gas disorder, poor welding seam uniformity, affecting production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

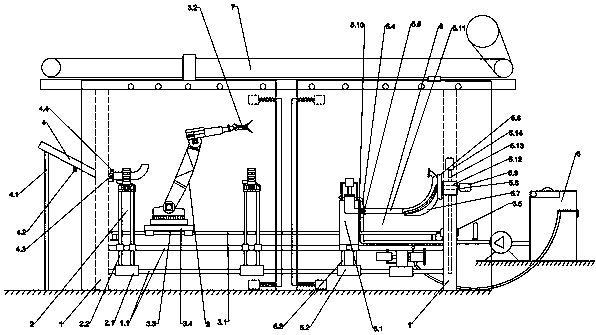

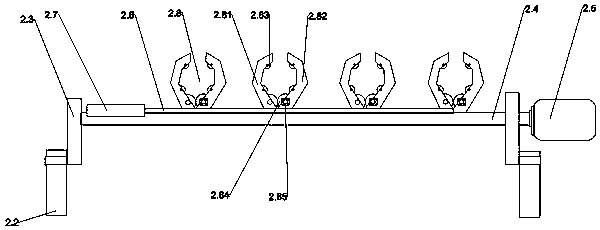

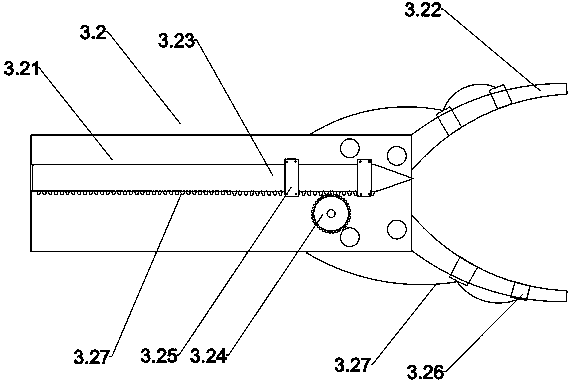

[0034] 1. A safe automatic welding equipment for exhaust manifolds, including equipment frame 1, single-stage welding table 2, welding handling inspection manipulator 3, flange slide 4, combined welding table 5 and polishing device 6; The equipment rack 1 is provided with four groups, and each two groups are fixedly connected by two upper and lower horizontal sliding rods 1.1. The single-stage welding table 2 has two groups, and the bottom of the single-stage welding table 2 is provided with a straight line. Motor I2.1, the linear motor I2.1 is sleeved on the sliding rod 1.1, the linear motor I2.1 is fixed with four support rods I2.2 on the top, and the support rod I2.2 is fixed on the top of the two On the group bracket 2.3, the middle of the bracket 2.3 is provided with a rotating shaft 2.4, the rotating shaft 2.4 passes through the bracket 2.3, the end of the rotating shaft 2.4 is connected with a turning servo motor 2.5, and the rotating shaft 2.4 is slidingly sleeved with a...

Embodiment 2

[0041] The structure and principle of this embodiment 2 are basically the same as that of embodiment 1, except that the lower part of the flange slide 4 is provided with a stopper cylinder 4.2. The stopper cylinder 4.2 can adjust the flange sliding pressure to avoid a large number of flanges. If the sliding pressure is too high, the clamping cylinder II cannot be fully clamped, causing the flange to fall.

Embodiment 3

[0043] This embodiment 3 is basically the same in structure and principle as embodiment 1, except that the piston chamber I6.11 and the piston chamber II 6.26 are equipped with a pressure detection device 6.27, and the pressure detection device 6.27 can detect grinding and extrusion The pressure is fed back to the control system to control the polishing pressure inside the exhaust manifold to improve the polishing quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com