Patents

Literature

84results about How to "No need to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

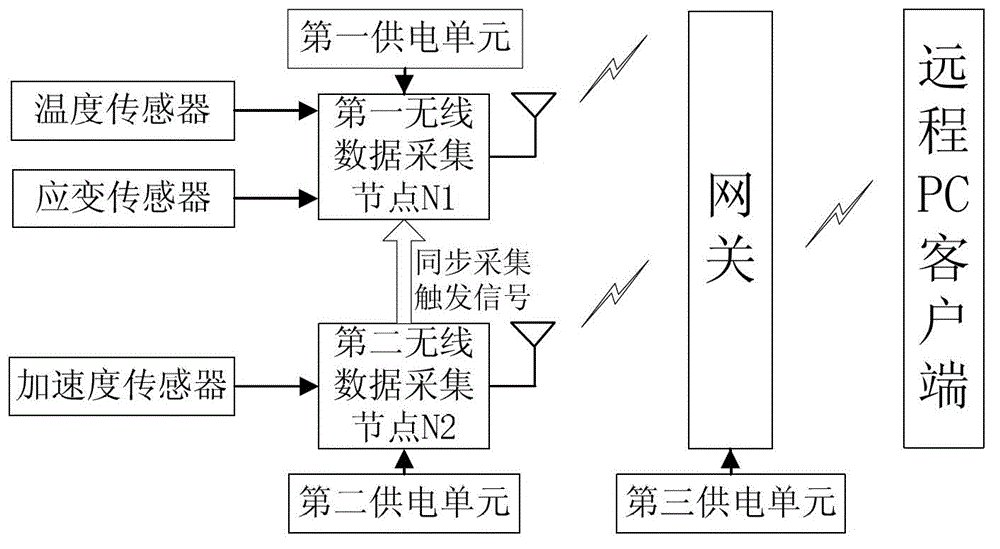

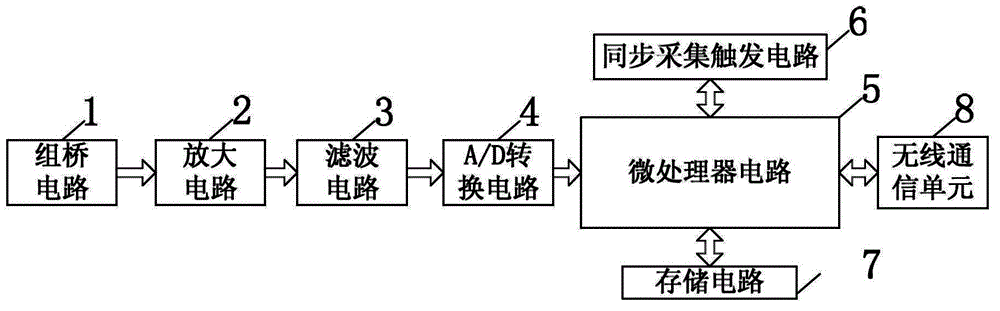

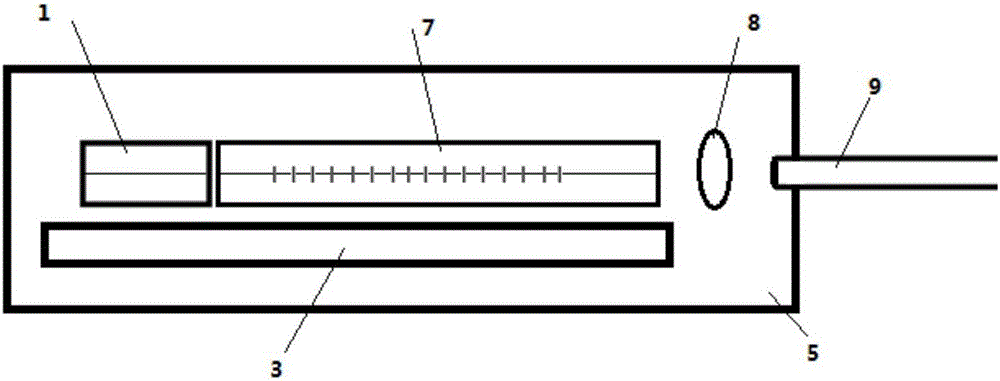

Method and device for on-line acquisition of steel rail temperature, strain and acceleration data

InactiveCN103332207AWill not affect driving safetySimple structureRailway auxillary equipmentRailway profile gaugesVibration accelerationOperation safety

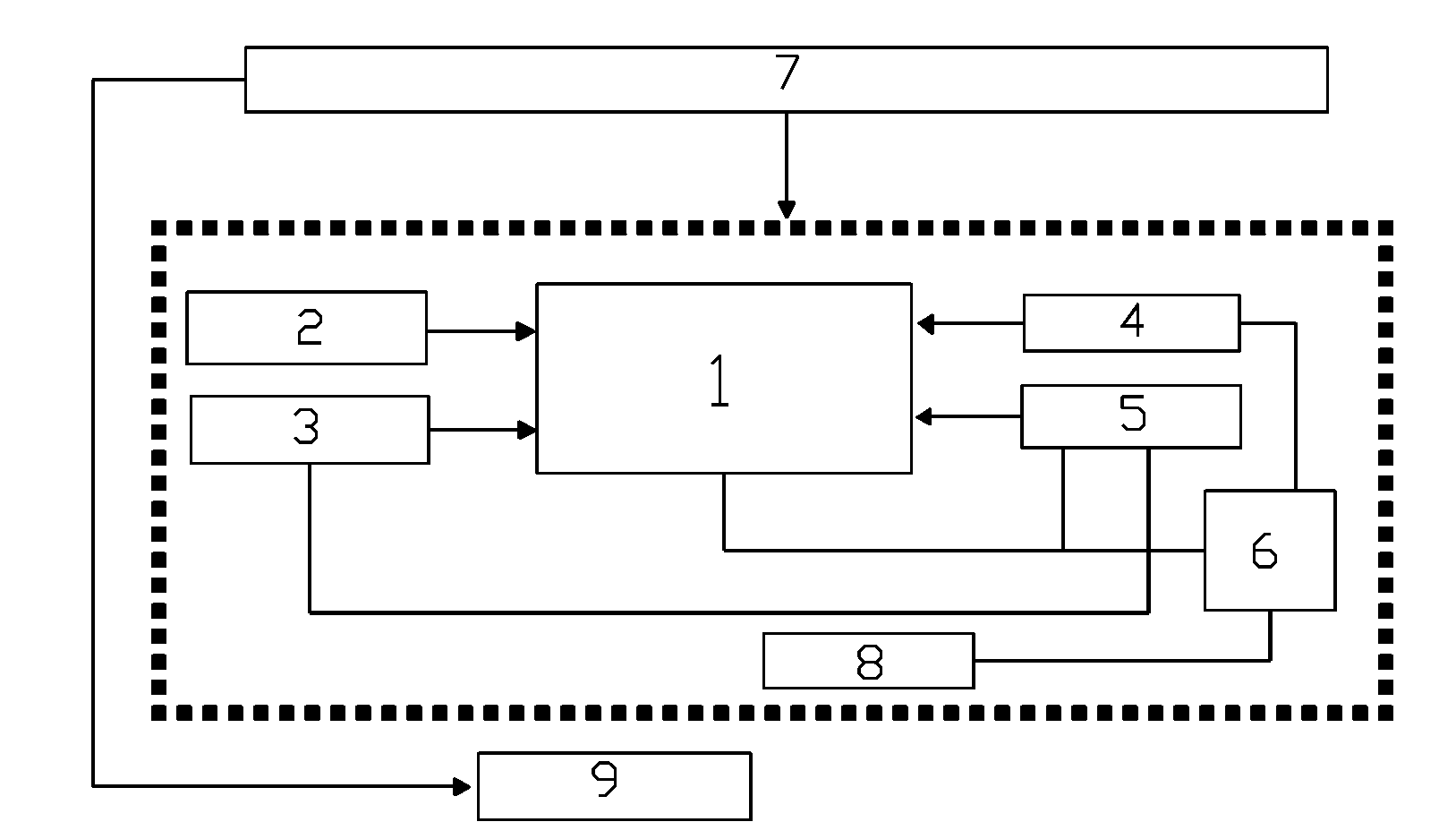

The invention relates to a method and a device for the on-line acquisition of steel rail temperature, strain and acceleration data, and belongs to the technical field of temperature, strain and vibration acceleration measurement. The device comprises a temperature sensor, a strain sensor, an acceleration sensor, a first wireless data acquisition node, a second wireless data acquisition node, a first power supply unit, a second power supply unit, a third power supply unit, a gateway and a remote PC client, wherein the first wireless data acquisition node and the second wireless data acquisition node are composed of a group bridge circuit, an amplification circuit, a filtering circuit, an A / D switching circuit, a microprocessor circuit, a synchronous acquisition trigger circuit, a memory circuit and a wireless communication unit; data transmission is realized by the means of the wireless communication; the first data acquisition node and the second data acquisition node are used for automatically acquiring static and dynamic data of a steel rail according to preset parameters. The device provided by the invention can automatically acquire the dynamic strain and acceleration signals of the steel rail when a train passes, and does not affect railway train operation safety or need human control at all.

Owner:DALIAN UNIV OF TECH

Method for preparing aluminum alloy anti-corrosion layer and electrolyte used in method

InactiveCN102758234ANo pollution in the processImprove pollutionAnodisationPlasma electrolytic oxidationIsolation layer

The invention discloses a method for preparing an aluminum alloy anti-corrosion layer and electrolyte used in the method. According to the invention, through micro-arc oxidization, the formed ceramic film layer is divided into an inner compact layer and an outer loose layer, and the inner compact layer is mainly used for providing protection for a substrate; the outer loose layer is filled by utilizing a closing method, so that the thickness of an isolation layer is effectively improved. According to the invention, the adopted micro-arc oxidization electrolyte and the closing liquid have no substances harmful to human body and environment, and are simple in components, easy to control and stable in process. Through adopting a composite salt system, the obtained ceramic film layer is uniform and compact, and has good resistance on all kinds of corrosive mediums.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

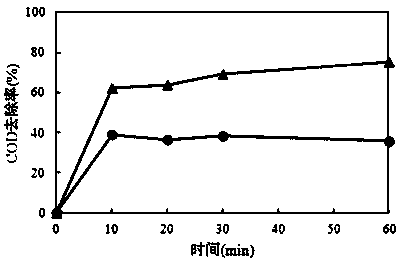

Fe-Mn double-metal heterogeneous Fenton catalyst taking molecular sieve as carrier as well as preparation method and application of catalyst

InactiveCN104209138AReduce processing costsSimple processMolecular sieve catalystsWaste water treatment from plant processingIonMolecular sieve

The invention provides a Fe-Mn double-metal heterogeneous Fenton catalyst taking a molecular sieve as a carrier as well as a preparation method and application of the catalyst. The preparation method comprises the following steps: mixing a MnSO4.H2O solution and a FeSO4.7H2O solution to obtain a mixed system, adding a NaY molecular sieve into the mixed system, uniformly mixing, adding citric acid into the mixed system, carrying out water bath reaction, and drying and calcining viscous substance obtained after the reaction to obtain the Fe-Mn / NaY supported heterogeneous Fenton catalyst which is used for treating papermaking wastewater. The heterogeneous Fenton catalyst prepared by the method can be recycled and easily separated from the waste water; no chemical sludge is generated in the reaction system; the treatment cost is low; the technological process is simple and easy to control; the Fe-Mn double-metal heterogeneous Fenton catalyst has a relatively bright actual application prospect; the pH application range is widened; the dissolution level of iron ions can be reduced; the Fe-Mn double-metal heterogeneous Fenton catalyst can be recycled; by virtue of a synergistic effect of Fe-Mn double-metal ions, the catalytic reaction activity can be improved.

Owner:TIANJIN UNIV

Grafting-modified rubber and preparation method thereof

The invention discloses a grafting-modified rubber and a preparation method thereof. The grafting-modified rubber is prepared by graft polymerization of rubber latex (1) and a nano-silica / poly(conjugated diene) composite emulsion (2) in the presence of an initiator, wherein a mass ratio of the dry basis of the rubber latex to the dry basis of the nano-silica / poly(conjugated diene) composite emulsion is 100: (0.1 to 100); based on the dry basis of the nano-silica / poly(conjugated diene) composite emulsion, the nano-silica / poly(conjugated diene) composite emulsion comprises 0.1 to 5 parts of surface functionalization-modified nano-silica; the nano-silica / poly(conjugated diene) composite emulsion has granularity of 50 to 80nm, number-average molecular weight of 100000 to 120000 and molecular weight distribution of 2 to 3; and the rubber latex is a homopolymer or a copolymer containing a poly(conjugated diene) compound and is prepared by emulsion polymerization.

Owner:PETROCHINA CO LTD

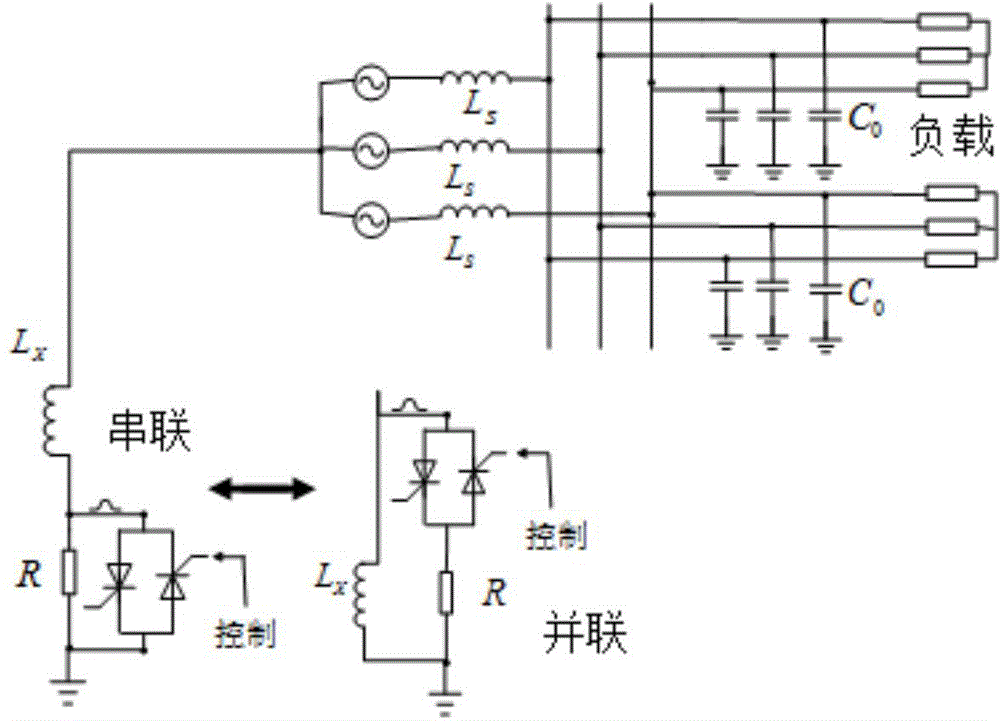

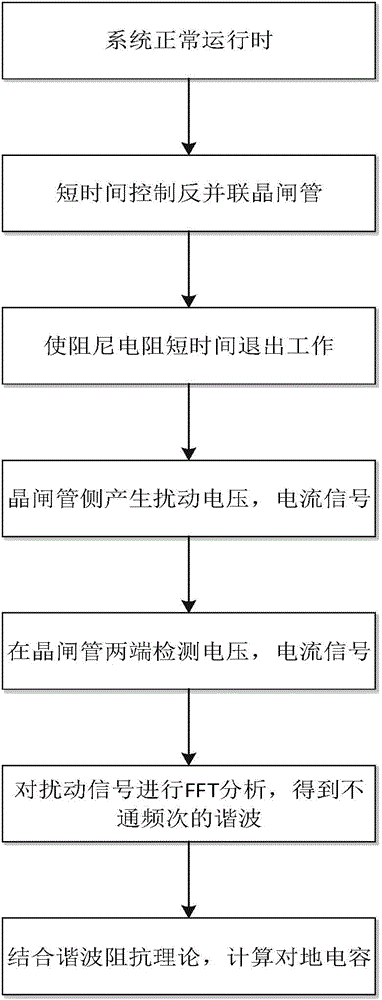

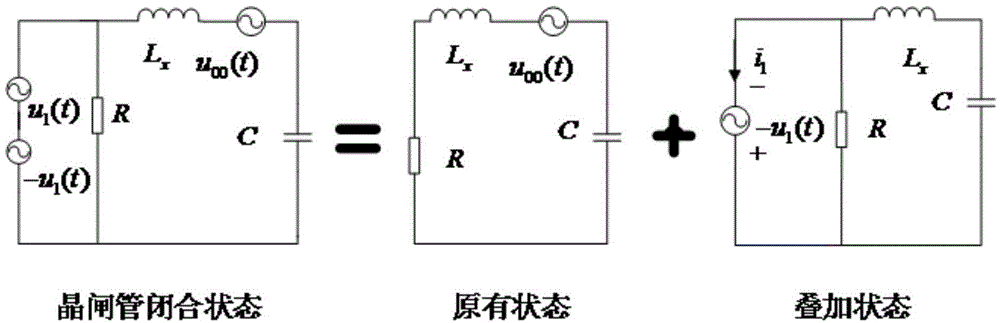

Ground capacitance detection method for neutral point via arc suppression coil grounding system

InactiveCN104917169ANo need to controlThe size is easy to controlResistance/reactance/impedenceEmergency protective arrangements for limiting excess voltage/currentDisturbance voltageOvervoltage

The invention discloses a ground capacitance detection method for a neutral point via arc suppression coil grounding system. A preset type arc suppression coil is in serial or parallel connection with a damping resistor so as to limit the neutral point displacement overvoltage during normal work of a power grid and an electronic power switch is gradually used for rapidly exiting from the damping resistor under the fault state due to the rapid action of the electronic power switch. According to the novel ground capacitance detection method for the preset type arc suppression coil comprising the electronic power switch, the working state of the electronic power switch of the damping resistor is switched through instantaneous control so as to generate the rich frequency component contained disturbance voltage and current pulse and the system ground capacitance is calculated through the disturbance voltage and current signal and the combination with an electronic power disturbance technology based harmonic impedance measurement method for self-tuning of the arc suppression coil.

Owner:SHANDONG UNIV

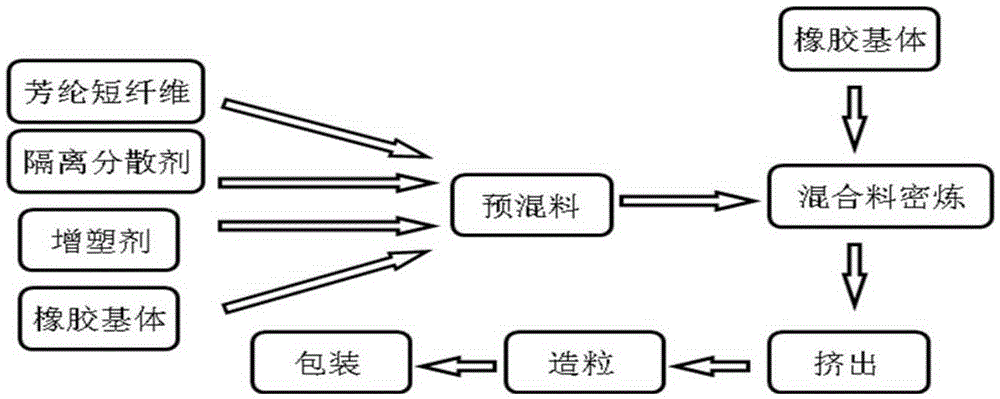

Formula and preparation method of pre-dispersion aramid short fiber masterbatch

The invention relates to the technical fields of polymer material modifying and processing, and discloses a formula and preparation method of a pre-dispersion aramid short fiber masterbatch. By selecting an appropriate isolating dispersant and plasticizer, aramid short fibers can be evenly dispersed in a rubber matrix and can effectively enhance the dispersed rubber matrix; by optimizing a production technology, the damage of the production process to the aramid short fibers is little, the length-diameter ratio retention rate of the fibers is high, no organic solvent is used in the process, no smoke or smell is generated, no pollution is generated, operation and control are easy, the equipment cost is low, and industrialized popularization is easy; the defects that the traditional modification effect is poor, and the product properties are inhomogenous are overcome.

Owner:HEILONGJIANG HONGYU NOVEL SHORT FIBER MATERIALS CO LTD

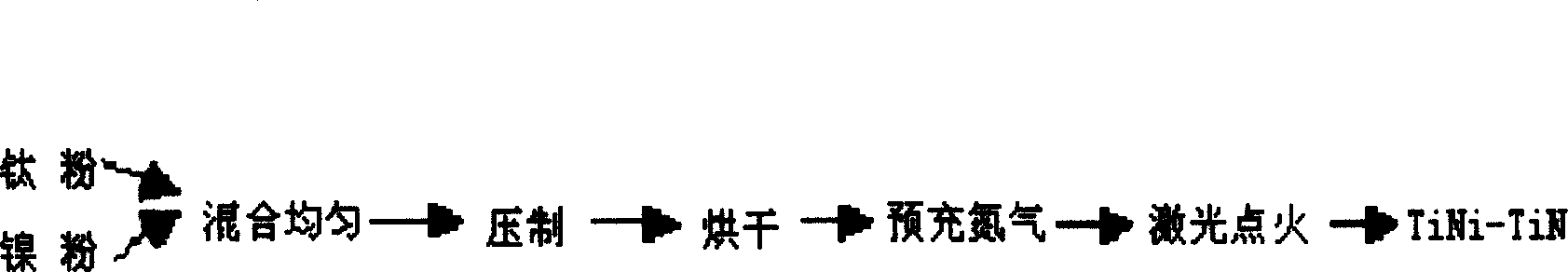

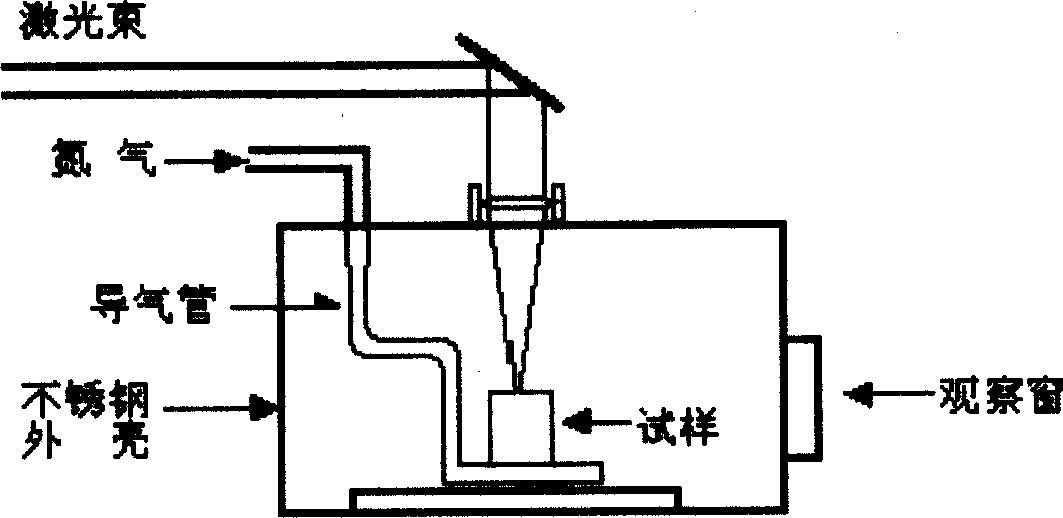

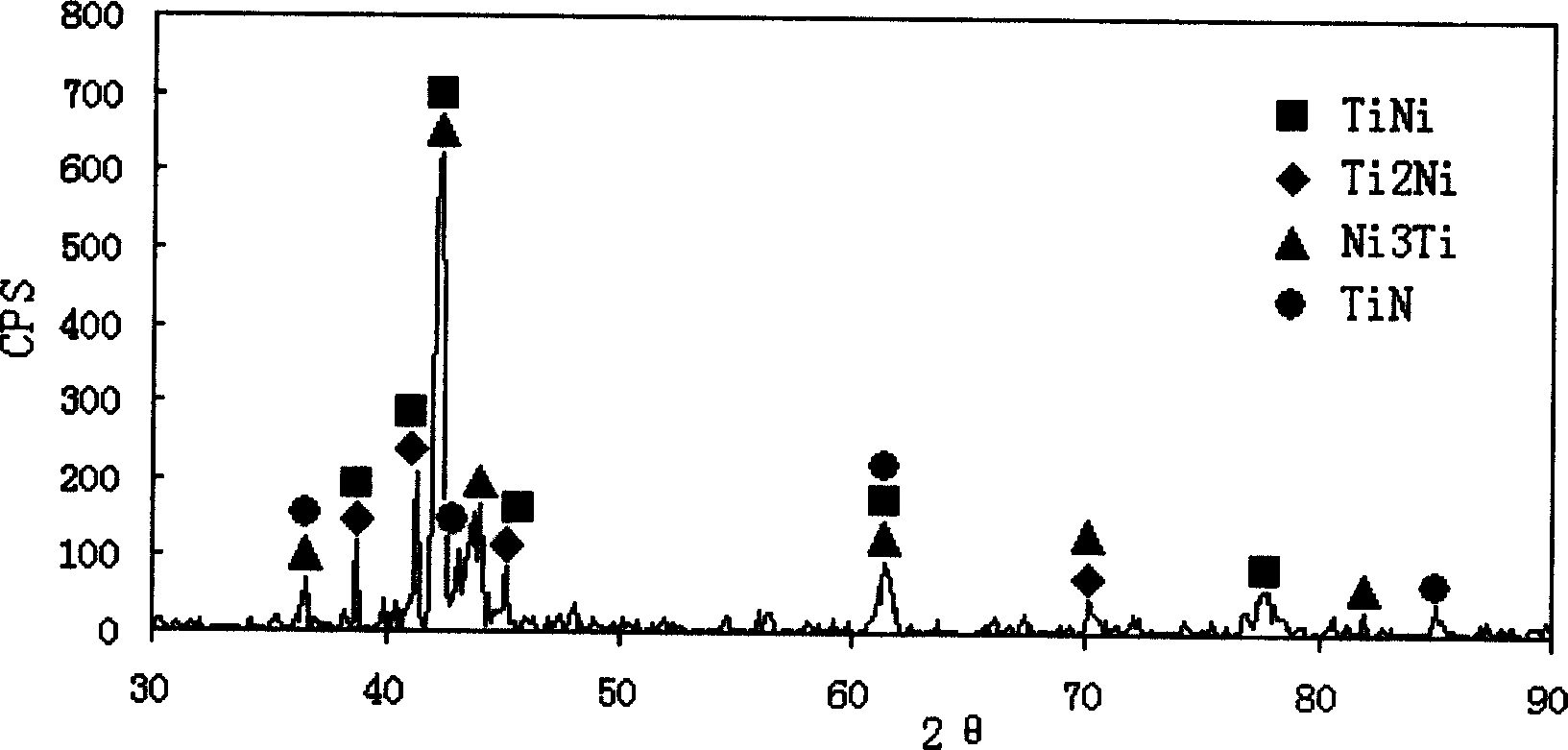

Method for synthesizing TiNi-TiN gradient material by laser-induction self-spreading under high temperature

InactiveCN1605413AEasy to synthesizeEfficient responseSelf-propagating high-temperature synthesisGradient material

The laser induced self-spreading high temperature gradient TiNi-TiN material synthesizing process includes the following steps: weighing and mixing metal Ti and Ni powder in the same molar ratio; pressing the mixture into cylindrical sample via maintaining the pressure of 20-50 KN for 1-4 min; keeping the sample at 80-150 deg.c for 1-3 min to eliminate water and partial gas; setting the sample on sample stage inside reaction container, sealing the container, introducing nitrogen in the flow rate of 5-10 L / min for over 2 min, and igniting with CO2 laser and Nd:YAG laser to induce self-spreading high temperature reaction.

Owner:SOUTH CHINA UNIV OF TECH

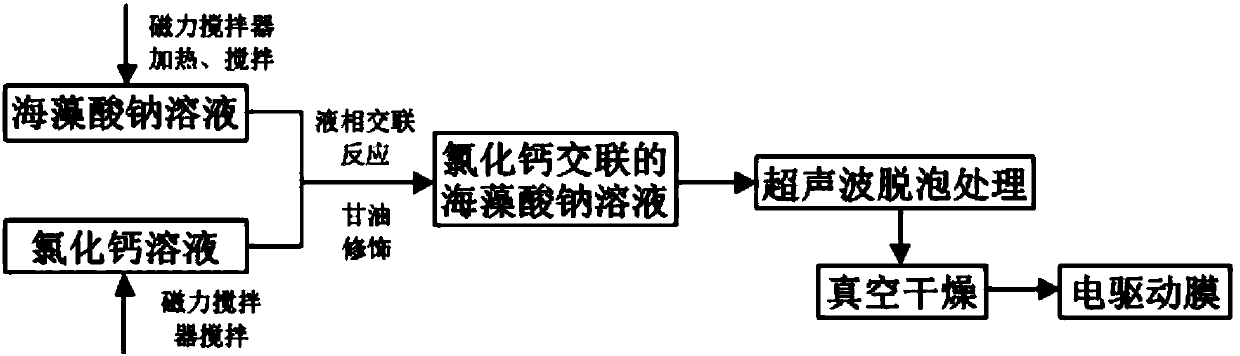

Preparation method of calcium chloride cross-linked sodium alginate electrically-driven film

The invention provides a preparation method of a calcium chloride cross-linked sodium alginate electrically-driven film. Sodium alginate and calcium chloride are subjected to cross-linking reaction according to certain mole ratio, then glycerinum is added to serve as a modifier, produced solution is subjected to ultrasonic defoaming and vacuum drying treatment and then produces the calcium chloride cross-linked sodium alginate electrically-driven film at one step. The method comprises steps of liquid phase cross-linking reaction, ultrasonic defoaming treatment and high-temperature drying. Themethod is green and environmentally friendly, low in cost, simple in steps, and suitable for large-scale production, ensures that the produced sodium alginate electrically-driven film can replace thetraditional driving structure in the field of flexible machinery and has good tensile strength and flexibility.

Owner:HARBIN ENG UNIV

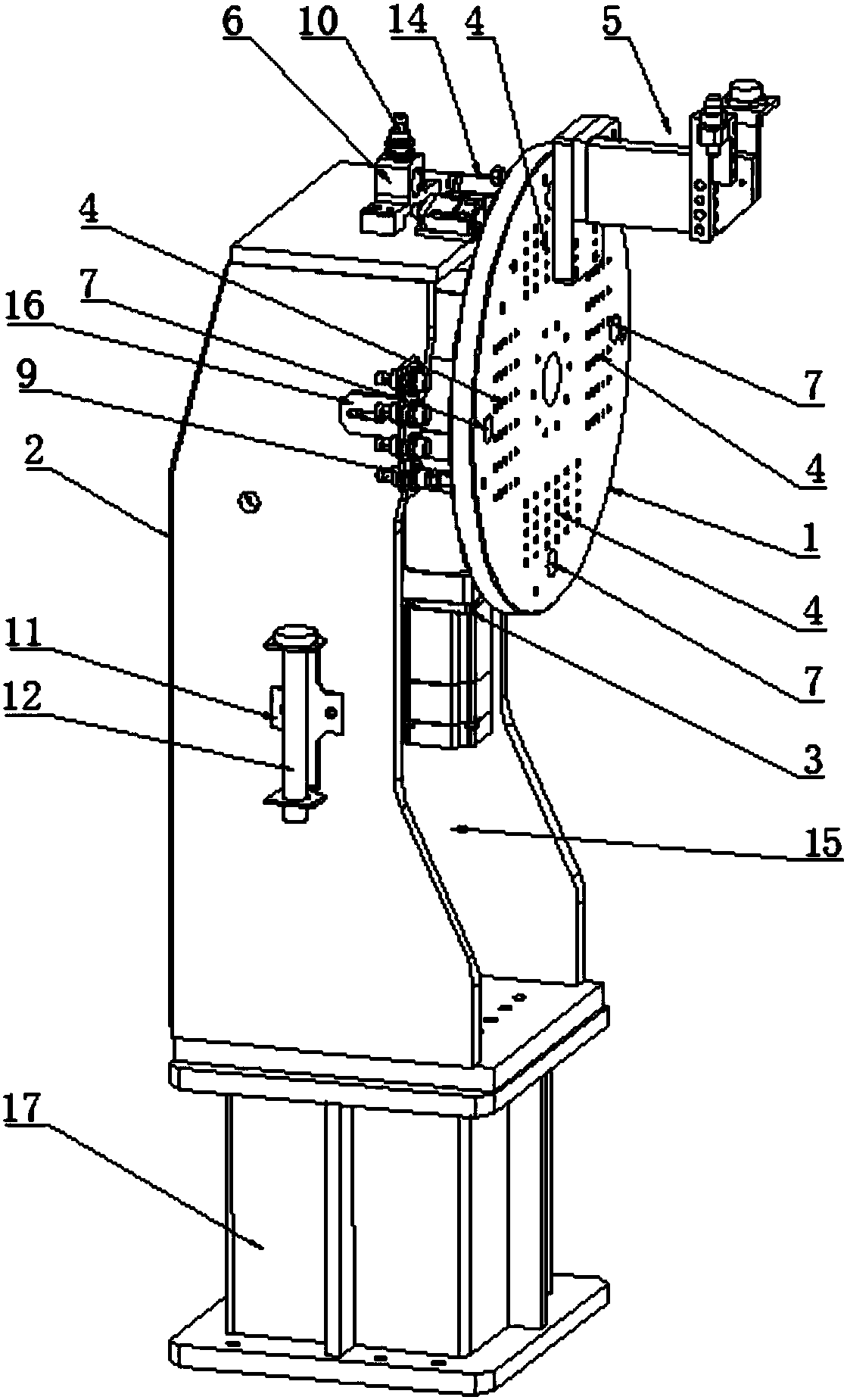

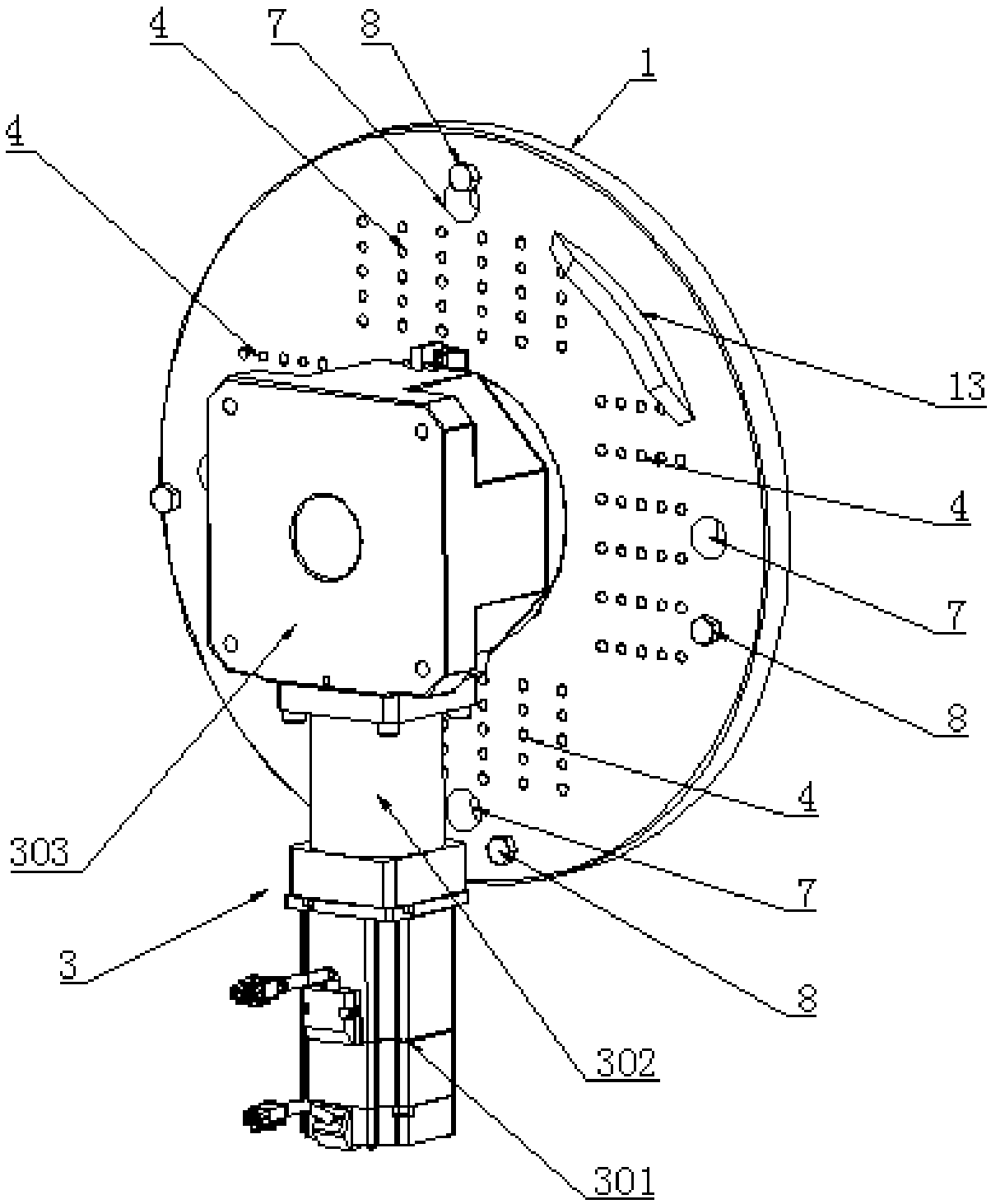

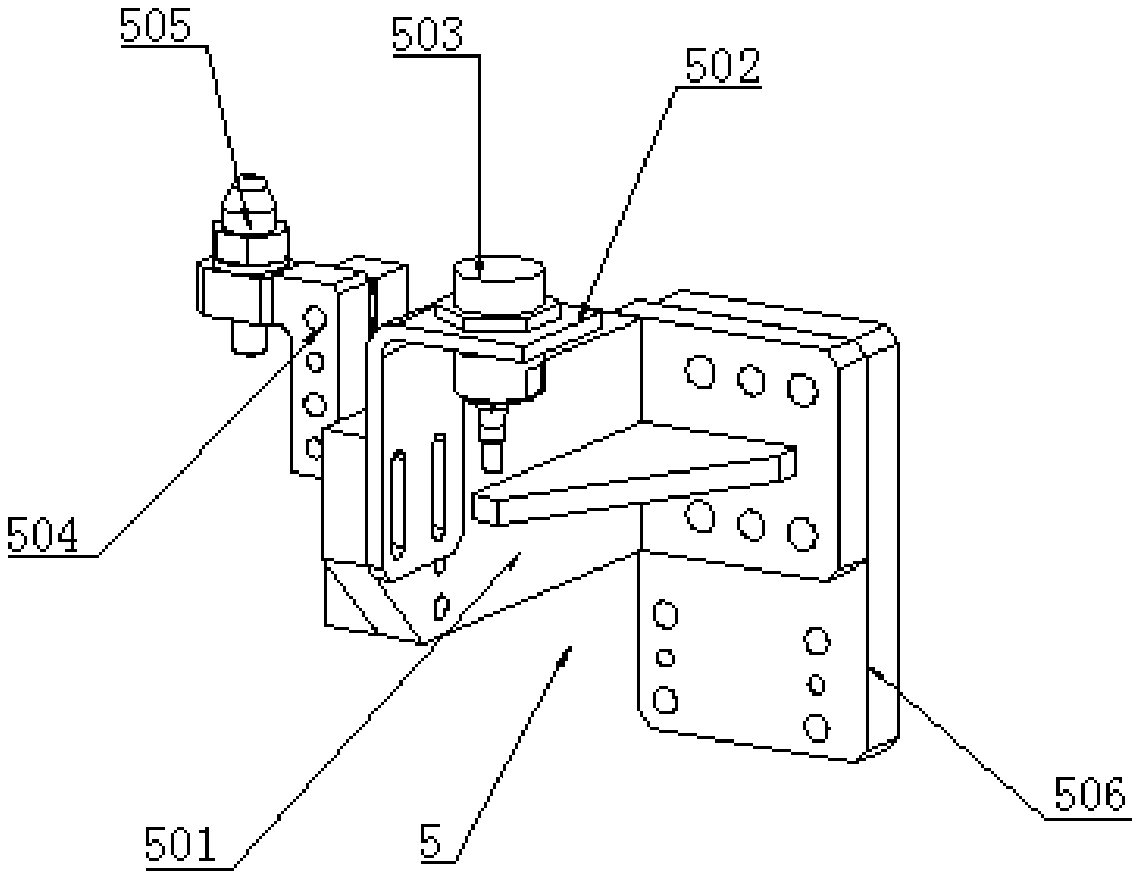

Windmill flexible positioning device for white car body welding production line

ActiveCN108176940ALow costAvoid multiple neck wrapsWelding/cutting auxillary devicesAuxillary welding devicesProduction lineWindmill

The invention discloses a windmill flexible positioning device for a white car body welding production line. The windmill flexible positioning device for the white car body welding production line comprises a rotary table rack, wherein a vertically arranged and rotatable windmill rotary plate is arranged on one side of the rotary table rack; a drive device for driving the windmill rotary plate torotate is arranged on the rotary table rack; multiple positioning stations arranged uniformly are arranged on a plate body of the windmill rotary plate; detachable positioning mechanisms for clampingworkpieces are arranged on the positioning stations; a station switching mechanism for controlling a rotation position of the windmill rotary plate is arranged between the windmill rotary plate and the rotary table rack; and an automatic emergency stop mechanism is arranged between the rotary table rack and the windmill rotary plate. The windmill flexible positioning device for the white car bodywelding production line provided by the invention is simple in structure, easy to maintain, low in cost, easy to control, good in universality, and capable of being adaptable to flexible positioning of multiple platform multi-car switching.

Owner:广州德恒汽车装备科技有限公司 +1

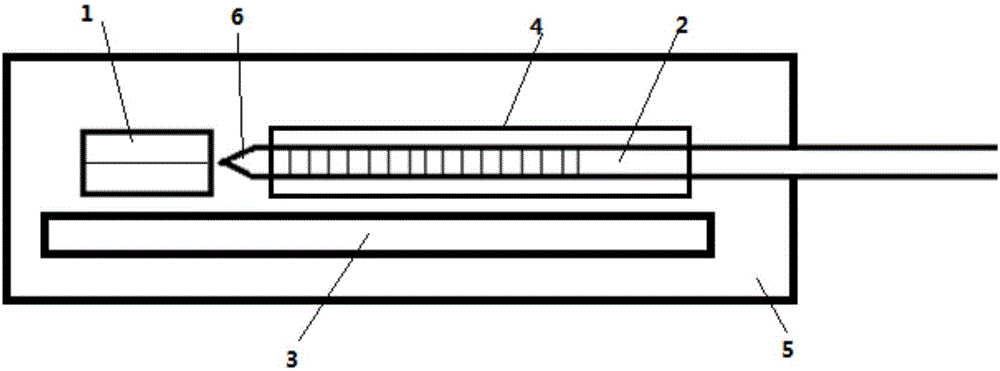

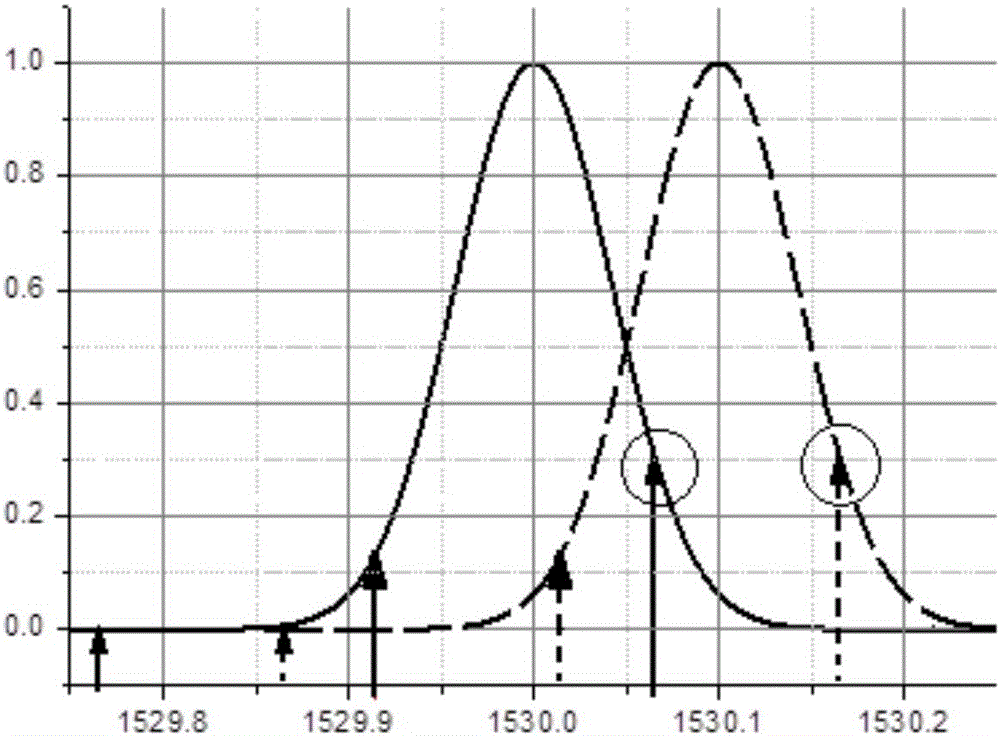

Wavelength thermal tuning device of external cavity semiconductor laser and synchronous thermal tuning method

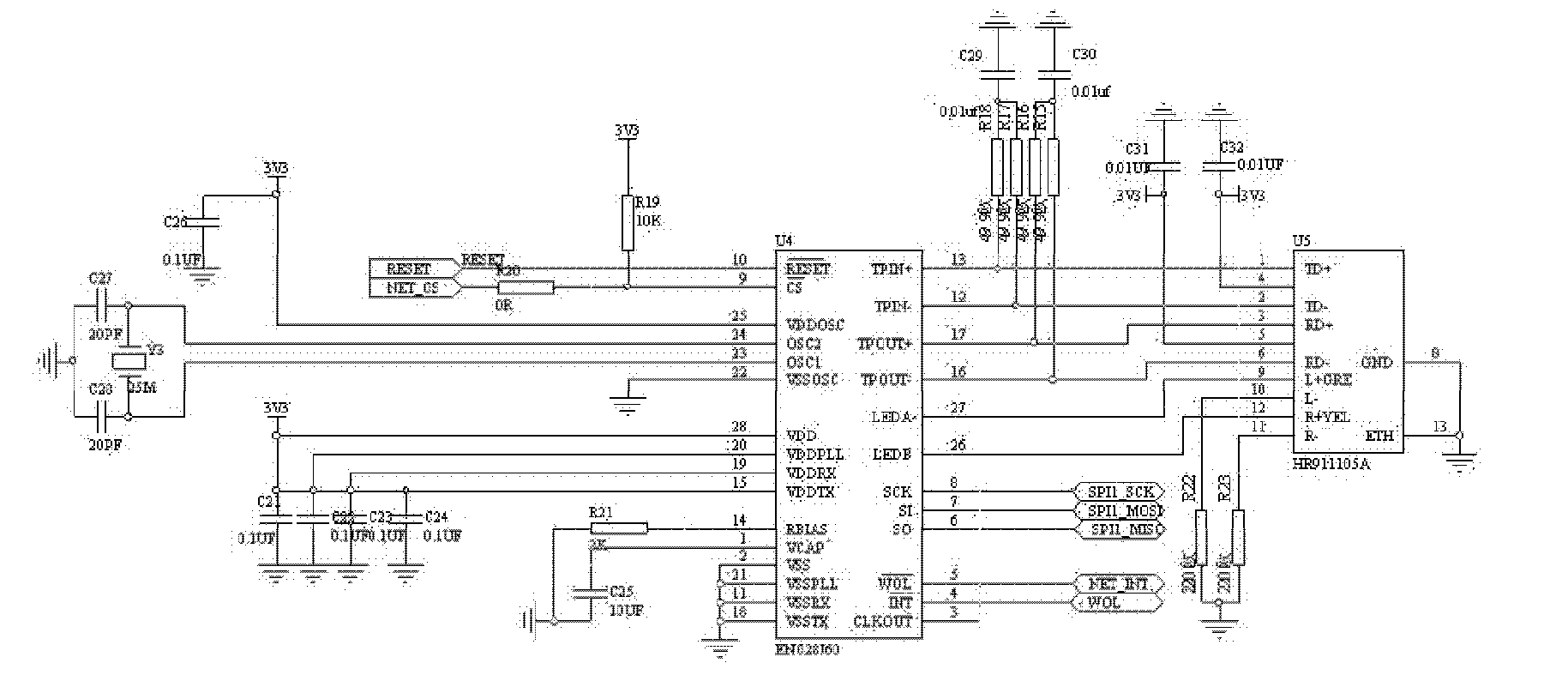

InactiveCN105006742ANo need to controlSimple structureLaser optical resonator constructionLaser output parameters controlGratingLine width

Provided are a wavelength thermal tuning device of an external cavity semiconductor laser and a synchronous thermal tuning method. The wavelength thermal tuning device comprises a semiconductor gain chip, a Bragg raster and a temperature controller. The Bragg raster is arranged along the laser output direction of the semiconductor gain chip. The semiconductor gain chip and the Bragg raster are arranged on the temperature controller. Through design of temperature sensitivity of an external cavity optical path, thermal drift of a laser cavity longitudinal mode is consistent with thermal drift of raster reflection spectra. When the temperature changes, synchronous drift of longitudinal mode distribution and raster reflection spectra is carried out, the laser keeps original working performances, and therefore wide-scope wavelength tuning is achieved. The wavelength tuning capability of a present narrow-linewidth external cavity semiconductor laser is raised.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

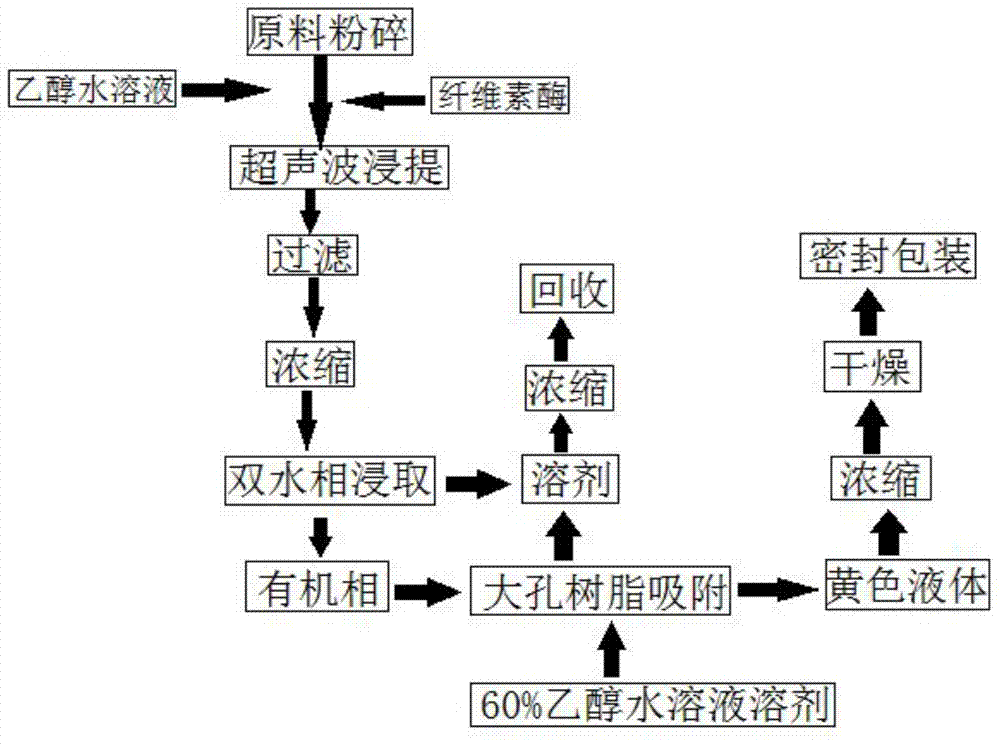

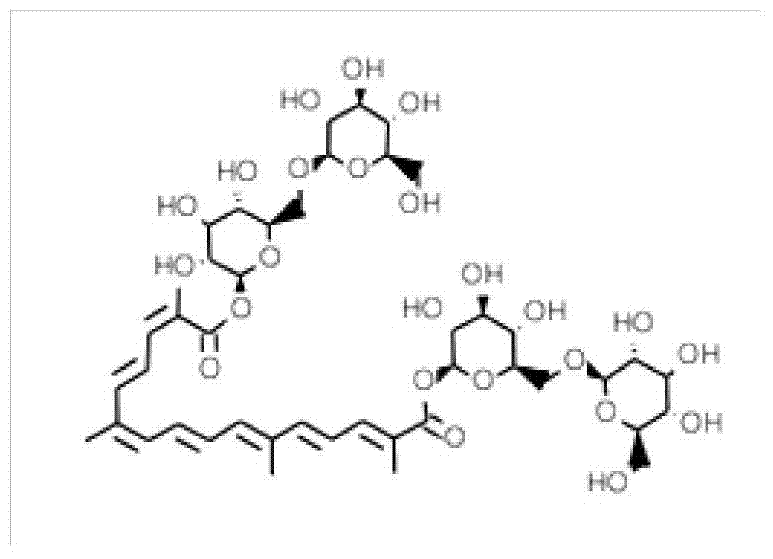

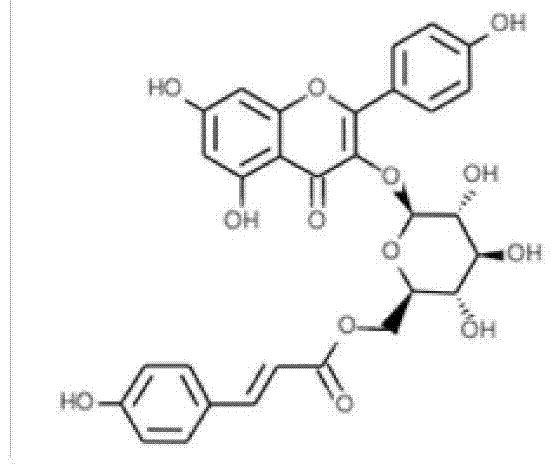

Method of extracting natural edible pigment

The invention relates to a pigment extraction technology, in particular to a method of extracting a natural edible pigment. The method comprises the following steps of firstly, extracting a yellow pigment of buddleja officinalis maxim by adopting enzyme-assisted ultrasonic wave so as to obtain filtrate a; secondly, concentrating the filtrate a to 0.25-0.5 time the volume, and extracting through a diphase water system so as to obtain an organic phase; lastly, absorbing and extracting the organic phase through a macroporous resin, concentrating a recovered solvent to obtain yellow liquid, and drying, sealing and packaging the yellow liquid to obtain a product. Through combination of three technologies, the extraction efficiency and the extraction rate of the yellow pigment of the buddleja officinalis maxim are greatly improved, the product purity is improved, processing steps are simplified, and the production cost is reduced.

Owner:贵州都匀市旭宝庭院茶叶有限公司

Intrinsically safe network voice controller for mining

ActiveCN102592629AImprove driving abilityImprove versatilityPublic address systemsRecord information storageSignal-to-noise ratio (imaging)Digital broadcasting

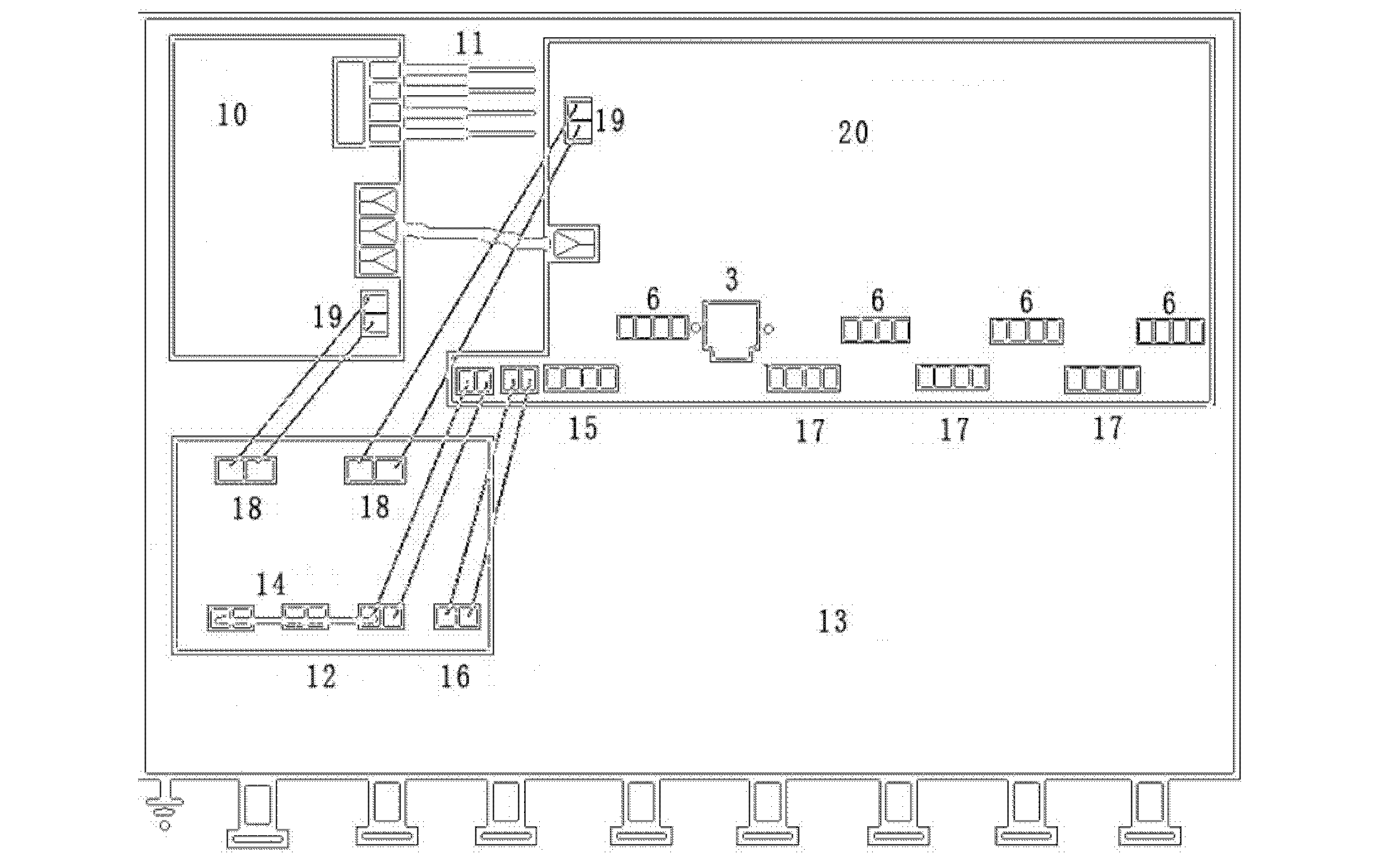

The invention discloses an intrinsically safe network voice controller for mining, comprising a CPU (central processing unit) circuit, wherein the CPU circuit is respectively connected with a network processing circuit, an SD (Secure Digital Memory) card circuit, two paths of audio coding and decoding circuits, an audio drive circuit and a power supply circuit for supplying power, the two paths of audio coding and decoding circuits are connected with at least one path of audio interfaces through the audio drive circuit, and the SD card circuit is directly connected with the audio coding and decoding circuits. The intrinsically safe network voice controller for mining, disclosed by the invention, is a part of underground digital broadcast of a coal mine, the digital broadcast is transmitted by a network, so that the signal to noise ratio is high, the transmission distance is far, and the digital broadcast has an advantage incomparable to that of the traditional constant pressure broadcast method. The intrinsically safe network voice controller for mining is suitable for such occasions as an underground sidewalk of mine, a parking place and a rest room, etc.

Owner:济南易安行信息科技有限公司

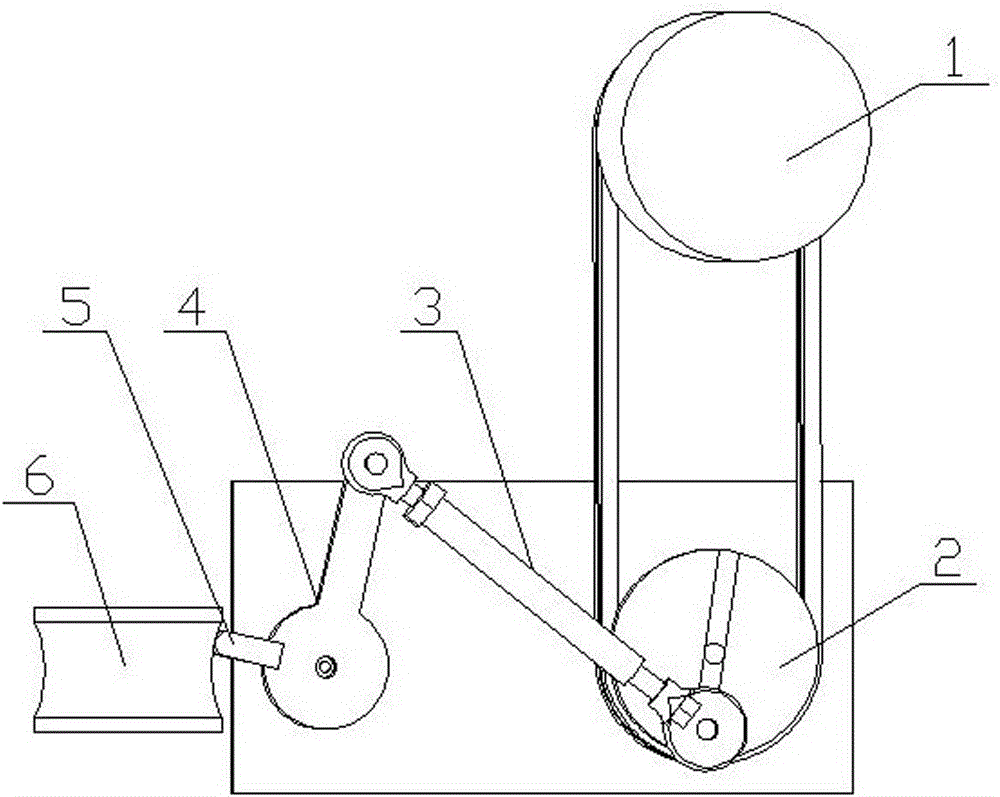

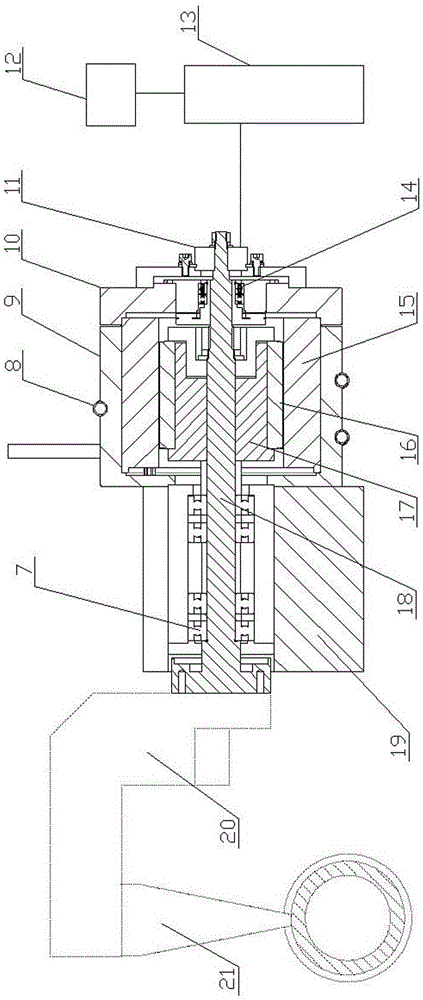

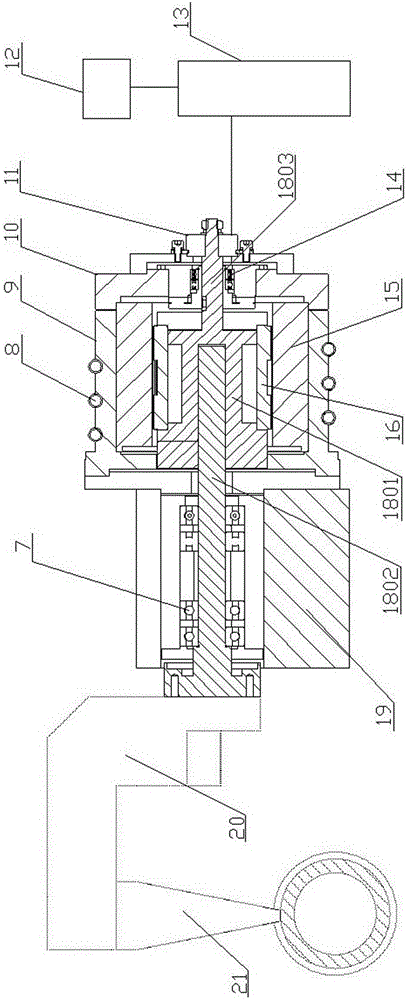

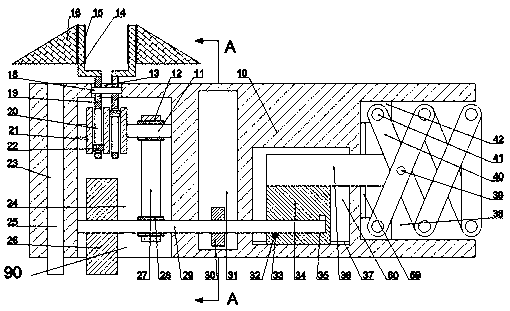

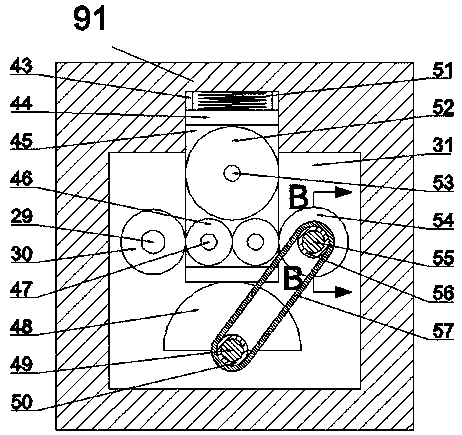

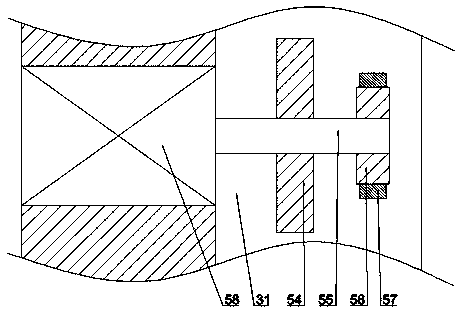

Driving device for swinging grinding head

ActiveCN105729303AGuaranteed machining accuracyNo vibrationGrinding drivesElectric machineryEngineering

The invention relates to a driving device for a swinging grinding head. The driving device for the swinging grinding head is characterized by comprising a machine shell. The machine shell is shaped like a cylinder with a closed end and an open end, and a covering plate is arranged at the open end of the cylinder. The closed end of the machine shell and the covering plate are both provided with central holes. A main shaft is arranged in the machine shell and penetrates through the central hole of the closed end of the machine shell and the central hole of the covering plate. A motor stator is fixed to the inner wall of the machine shell. A motor rotor is fixed to the section, inside the machine shell, of the main shaft. A supporting seat is fixed to the outer side of the closed end of the machine shell. The section, on the outer side of the closed end of the machine shell, of the main shaft is rotationally matched with the supporting seat through a bearing. The end, corresponding to the covering plate, of the main shaft is connected with an encoder, the encoder is connected with a servo driver through a wire, and the servo driver is connected with a power source through a wire. The driving device is used for driving the swinging grinding head to carry out ultra-accurate grinding machining, equipment vibration is small, the angle adjustment is accurate, the grinding speed is high, the problems of crawling and inching are avoided, the machining accuracy of workpieces is high, and the maintenance cost of a mechanism is low.

Owner:无锡天任电子有限公司

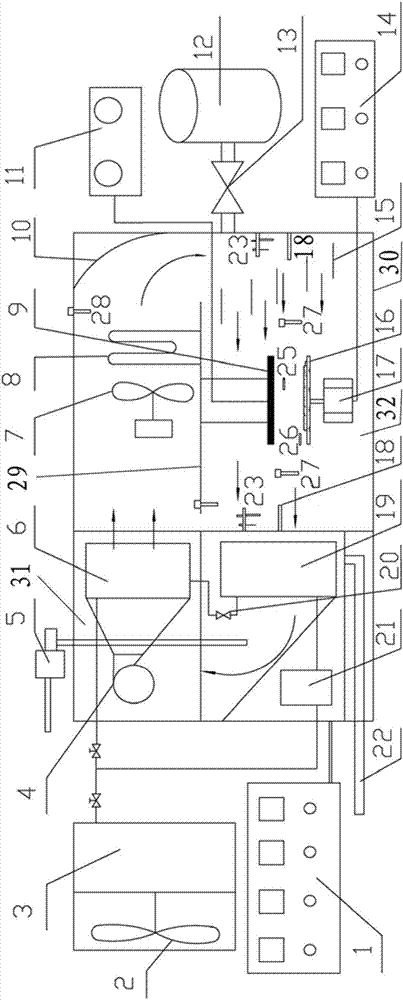

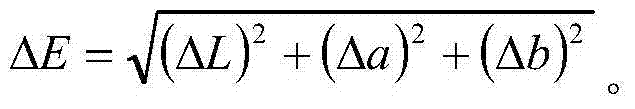

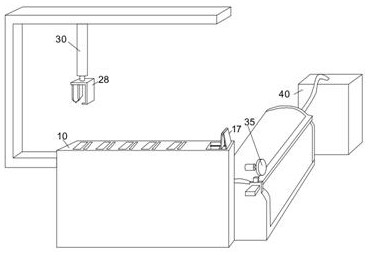

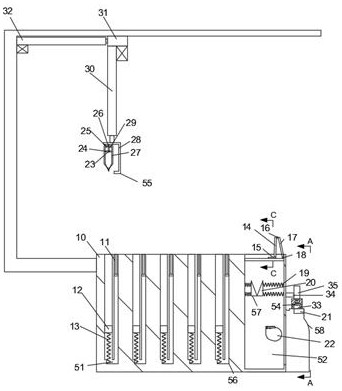

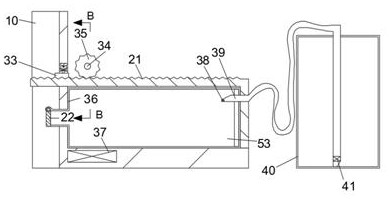

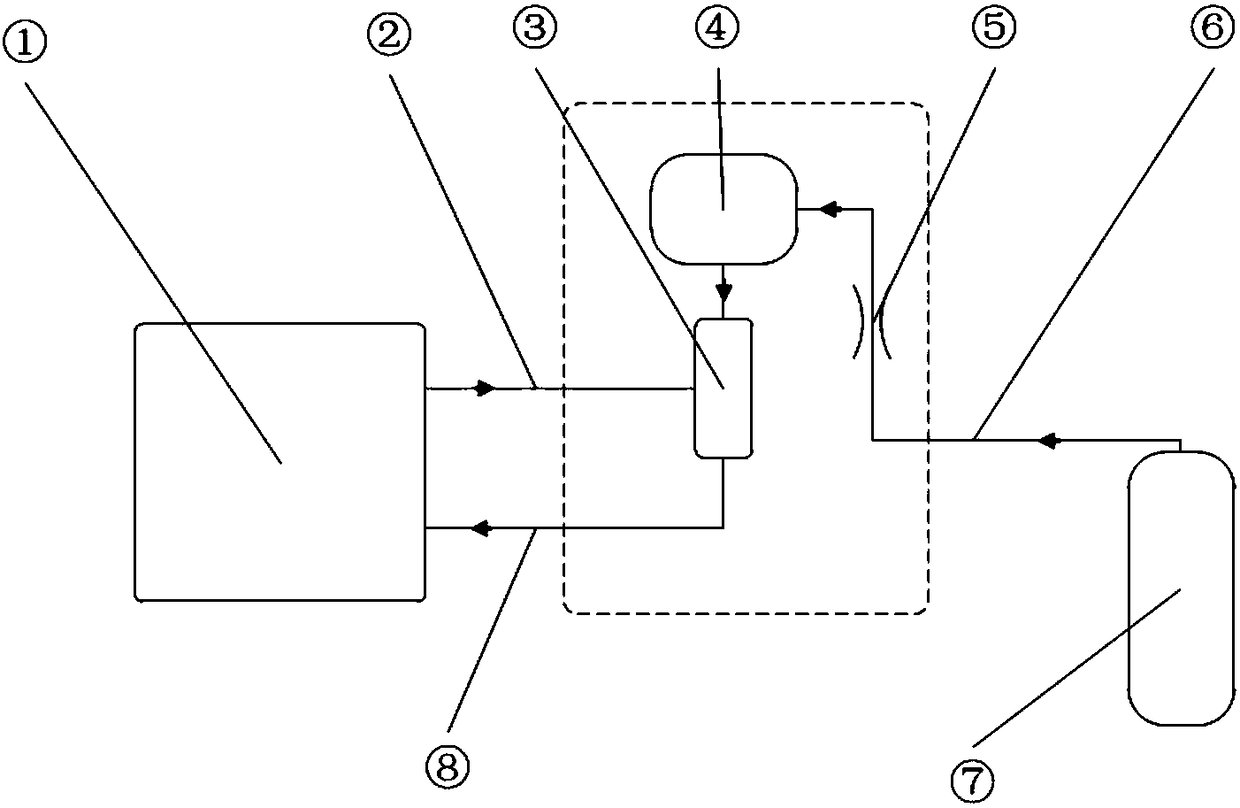

Ultrasonic-reinforced controlled atmosphere drying method and device

ActiveCN104322655AImproved heat conditionEnhance heat and mass transferFruits/vegetable preservation by dehydrationDrying timeLow oxygen

The invention discloses an ultrasonic-reinforced controlled atmosphere drying method and device. According to the method, when controlled atmosphere hot air is used for drying a material, the material is subjected to a direct contact ultrasonic treatment. With the ultrasonic-reinforced controlled atmosphere drying method provided by the invention, an oxidation reaction process during a drying process is effectively inhibited, such that effective components in the material are protected, color browning is effectively inhibited, and a problem that nutrients are prone to oxidative degradation under conventional hot air drying is solved. The direct contact ultrasonic treatment has a synergistic effect with controlled atmosphere drying under a low-oxygen environment. With the method, product quality is ensured, and ultrasonic energy is directly transferred into the material, such that water content migration rate of controlled atmosphere drying is effectively improved, and energy utilization rate and mass transfer reinforcement efficiency are improved. Therefore, drying efficiency is increased and drying time is shortened, and problems of low drying rate and poor product quality of conventional hot air drying are solved. The method and the device have a good application prospect.

Owner:HENAN UNIV OF SCI & TECH

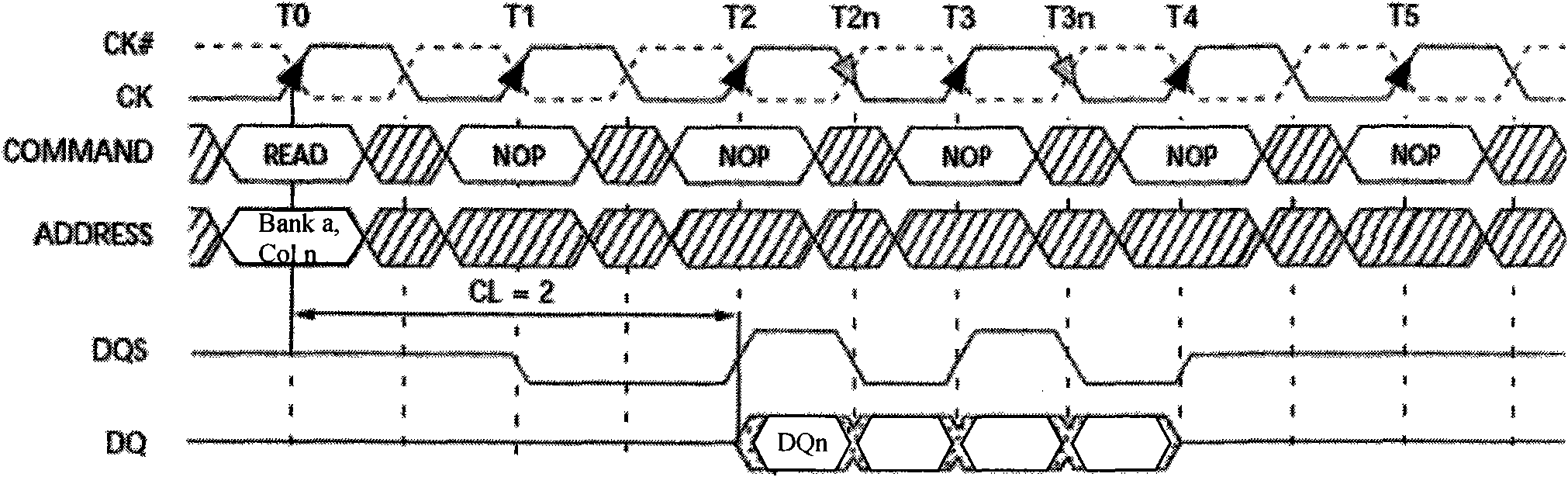

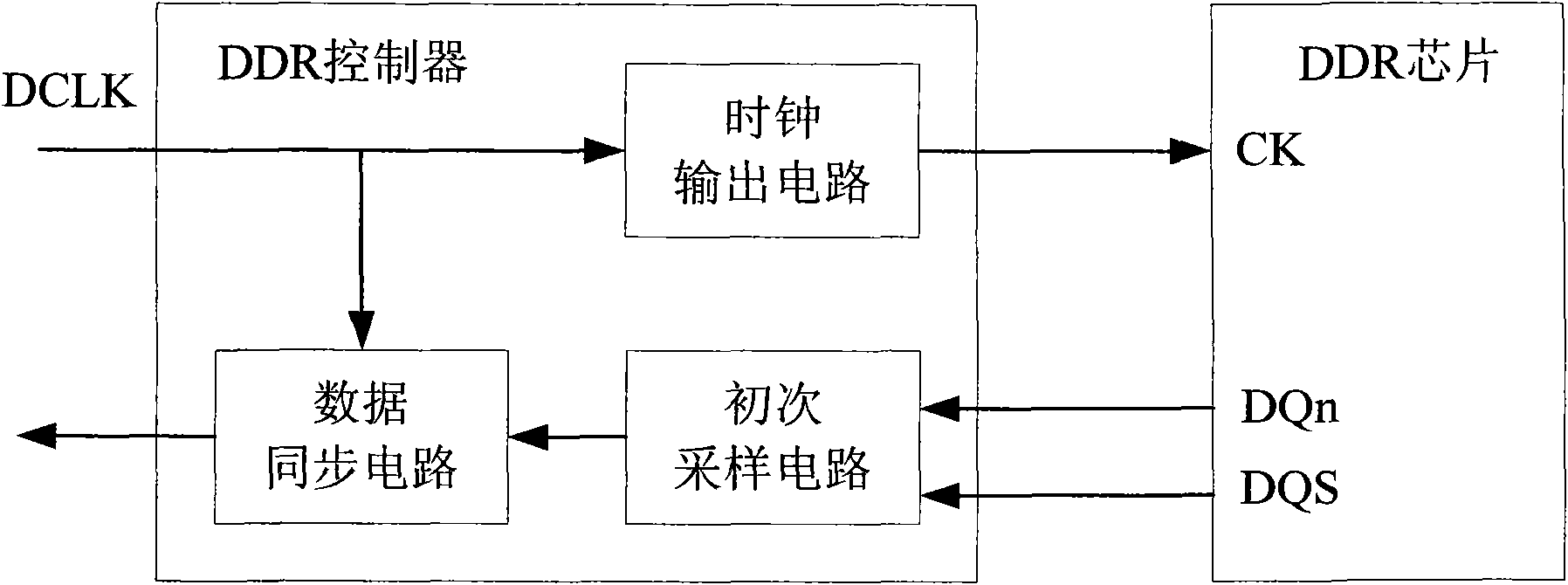

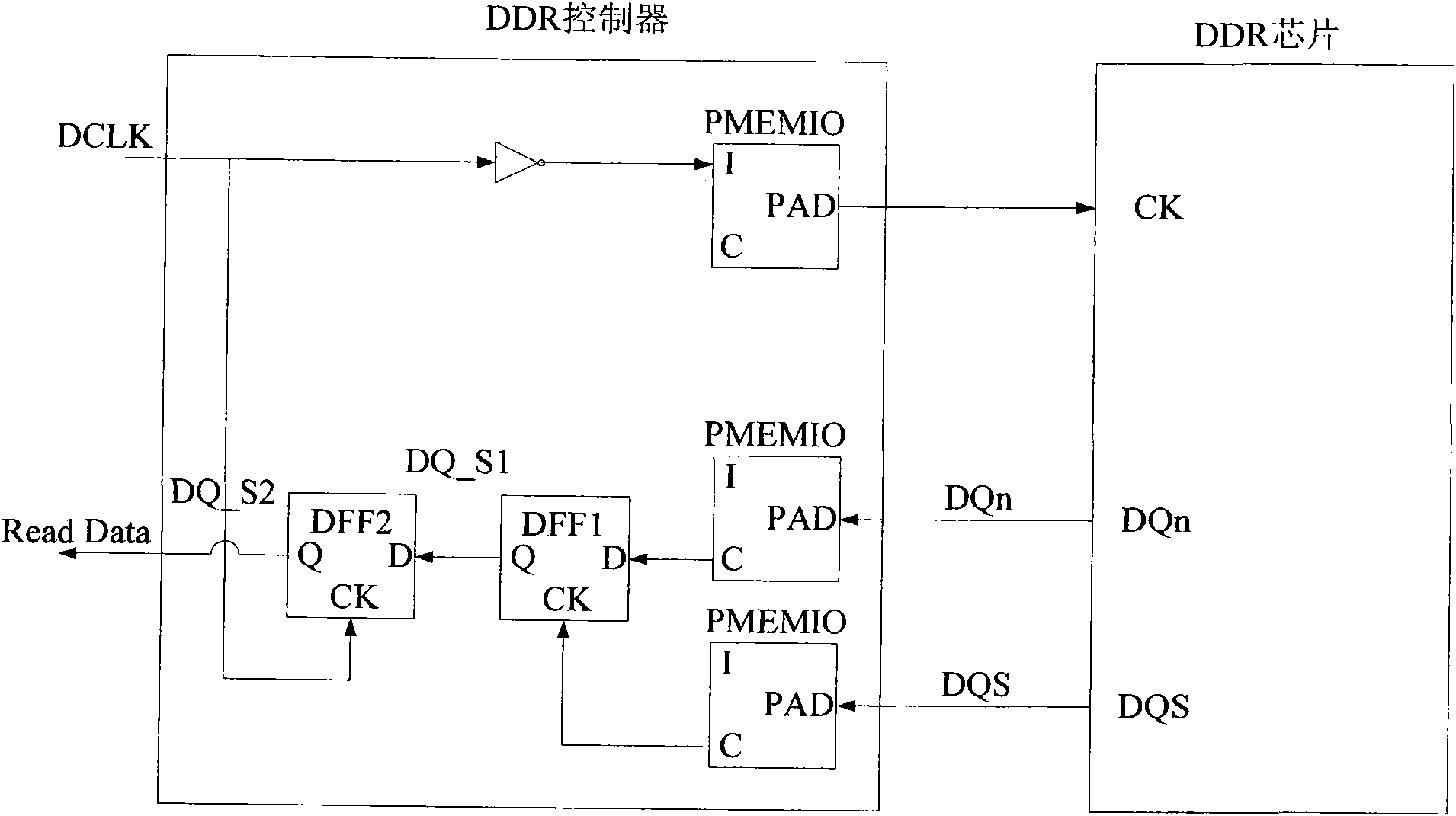

Temperature self-adaptive adjustment method for read data sampling and device thereof

InactiveCN101645301ANo need to controlImplement read data samplingDigital storageElectric digital data processingData synchronizationControl store

The invention provides a temperature self-adaptive adjustment method for read data sampling and a read data sampling device thereof. The device comprises a clock output circuit, a primary sampling circuit, a data synchronous circuit and a temperature difference compensating circuit, wherein, the temperature difference compensating circuit is used for respectively carrying out secondary sampling on the read data output by the primary sampling circuit with the utilization of sampling clocks CLK21 and CLK22. The method comprises the following steps: delaying and then outputting the read data sampled by the CLK21 to K*T when a working temperature is less than a threshold temperature, otherwise, directly outputting or delaying the read data sampled by the CLK22 to (k-1)*T and then outputting the data; and taking an internal clock of a storage controller or the delayed signal thereof as a sampling clock CLK3 by the data synchronous circuit, and sampling the read data output by the temperature difference compensating circuit or the delayed data thereof. The method can help stably sample the read data under a high temperature and a low temperature without software control.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

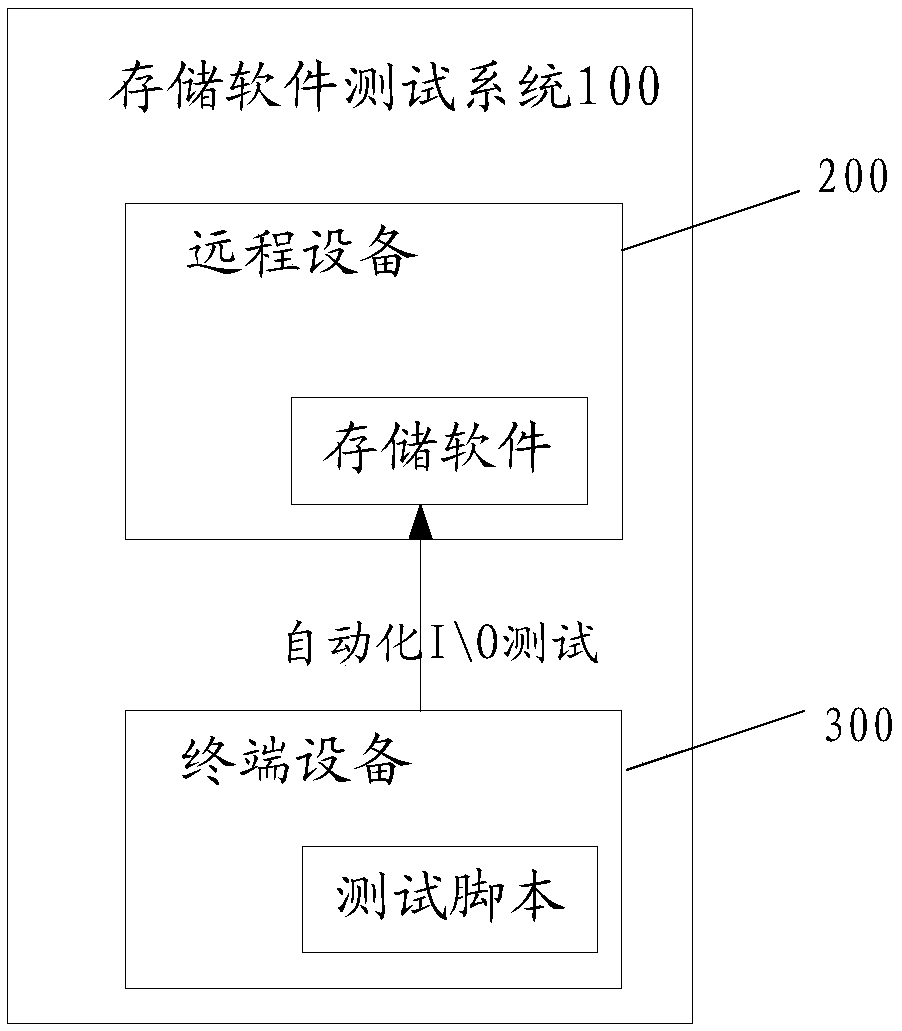

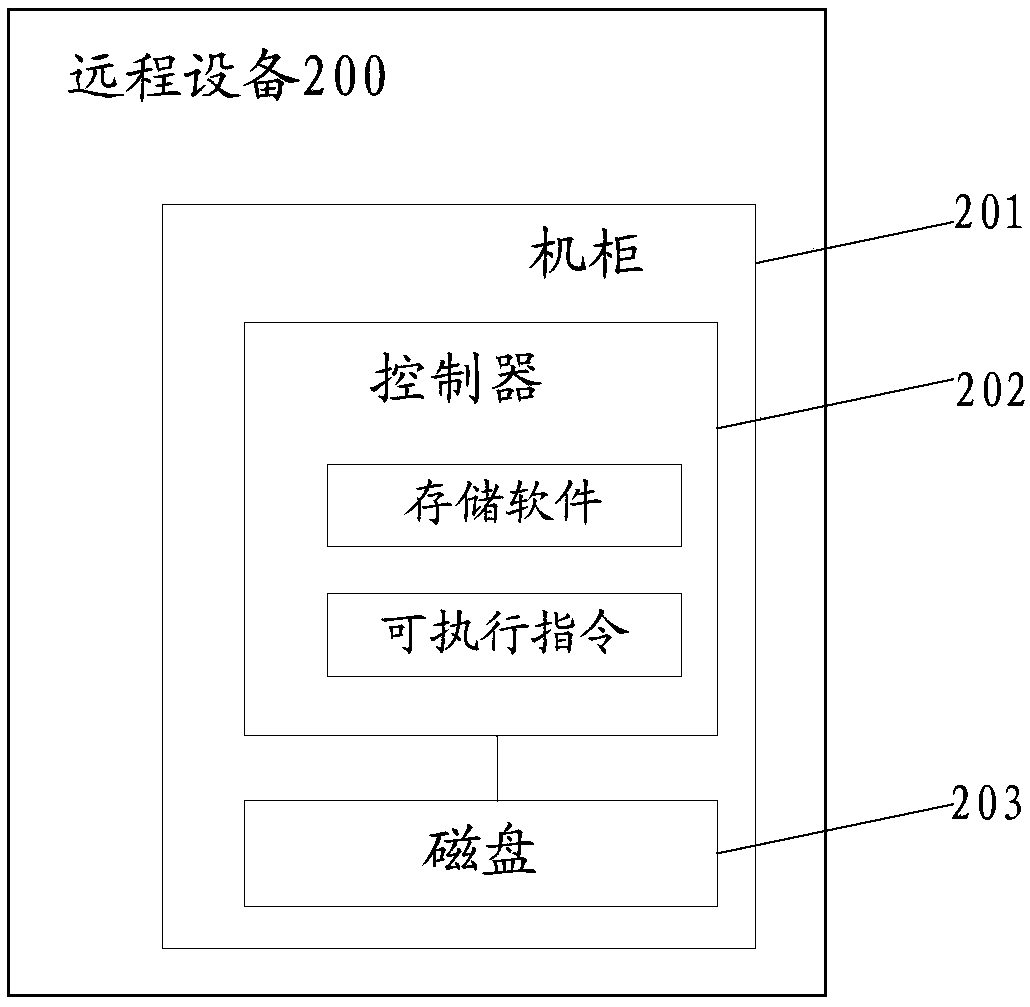

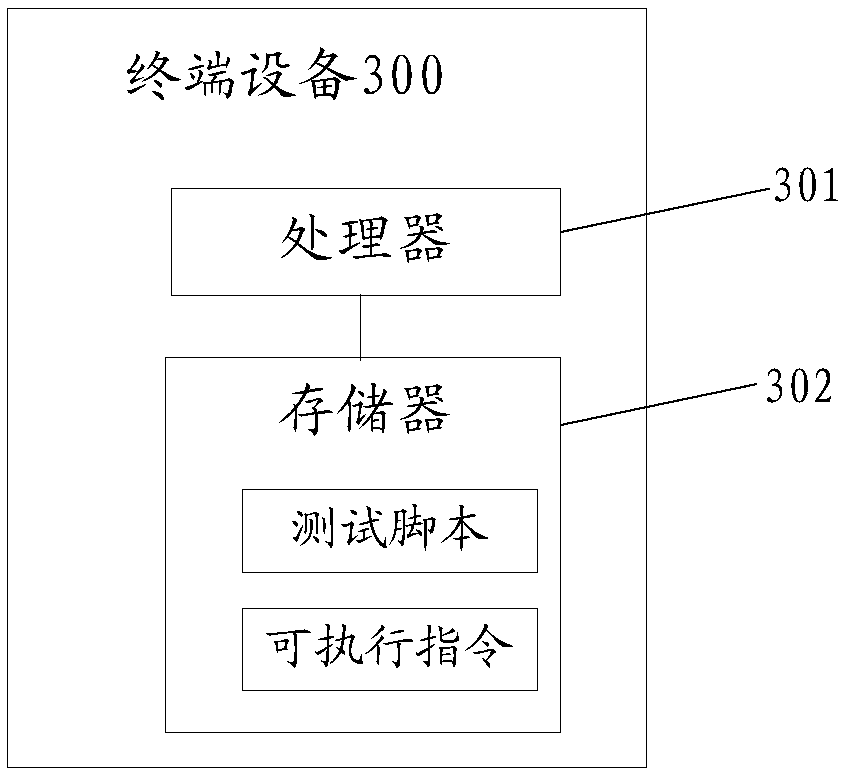

Storage software testing method, apparatus and device

ActiveCN108984419AImplement automated testingDoes not require artificial ginsengSoftware testing/debuggingTest efficiencyTest script

A storage software testing method is provided. In the method, a terminal device controls the remote device to start the storage software, and the remote device monitors the process and continuously feeds back the process state information to the terminal device so as to inform the process to be on-line or hung up, so that the terminal device automatically controls the execution of the test scriptin turn according to the real state of the process. If the process hangs up, the remote device automatically backs up the dump file and log file of the test script being executed when the process hangs up, and tries to restart the process; When the process hangs up, the terminal device creates a tag file and waits for the process to restart before executing the next test script until all the testscripts for the storage software are executed. It can be seen that this method can realize the automatic test of storage software, without manual control, reduce human cost, avoid human error, and greatly improve the test efficiency.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

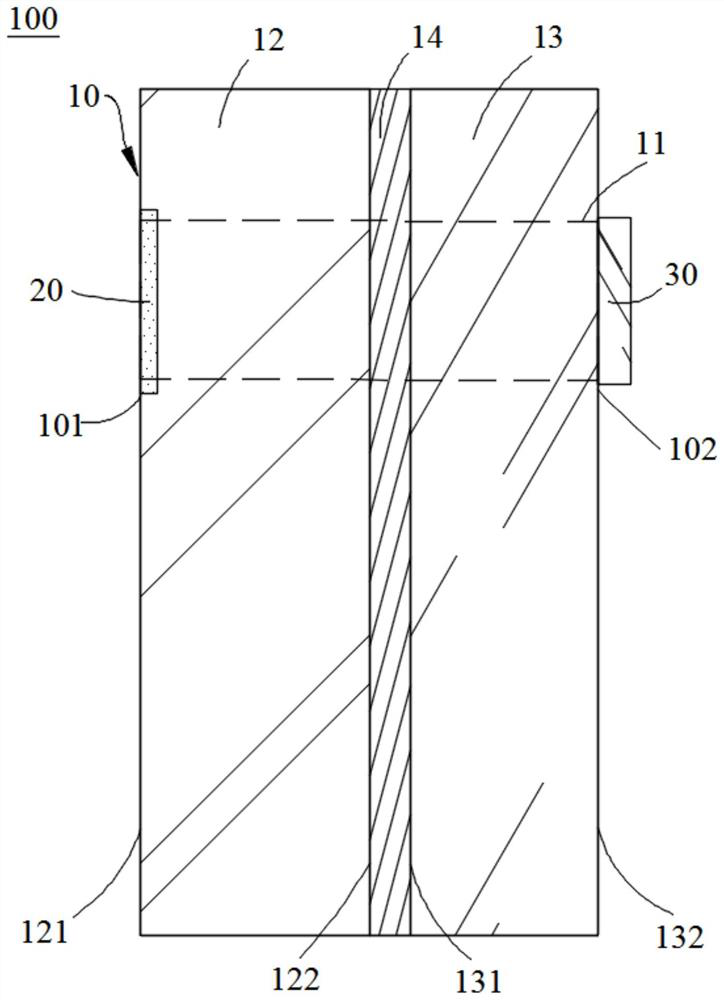

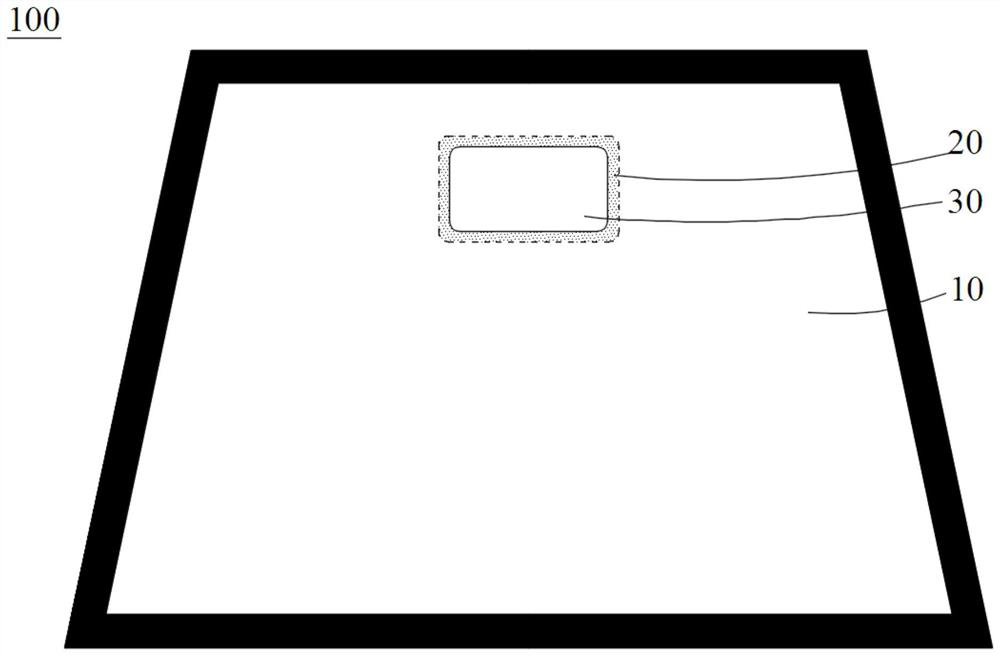

Vehicle window glass, preparation method thereof and vehicle

PendingCN114312248AImprove pollutionNo pollution in the processWindowsAntiglare equipmentLaser etchingEngineering

The invention discloses vehicle window glass and a preparation method thereof and a vehicle, the vehicle window glass comprises a glass body, the glass body is provided with an outer surface and an inner surface which are opposite to each other, and the glass body is provided with a signal transmission part for a signal of an optical sensor to pass through; an infrared anti-reflection structure formed through laser etching is arranged on the outer surface of the glass body, and in the thickness direction of the glass body, the projection of the infrared anti-reflection structure on the signal transmission part covers the signal transmission part. According to the technical scheme provided by the invention, the signal transmittance of the optical sensor can be improved, and the working requirements of the optical sensor in the fields of intelligent driving and the like are met.

Owner:FUYAO GLASS IND GROUP CO LTD

Method for improving moisture absorption performance of kapok fiber through corona treatment

InactiveCN105821646AGood hygroscopicityImprove dyeing effectUltrasonic/sonic fibre treatmentBleaching apparatusCarboxyl radicalKapok fiber

The invention relates to a novel method for improving the moisture absorption performance of kapok fiber by using corona treatment technology to modify the surface of the kapok fiber. The method comprises the following steps: subjecting the kapok fiber to pretreatment with a mixture of 6 to 10 g / L of hydrogen peroxide and 4 to 8 g / L of tetraacetyl ethylenediamine (TAED) so as to remove wax and impurities on the surface of the kapok fiber, which allows the kapok fiber to have certain whiteness; and then combing the kapok fiber having undergone pretreatment and then placing the kapok fiber on a corona discharge instrument for discharging treatment of the kapok fiber, wherein treatment voltage is 6 to 12 kV, treatment time corresponding to each group of treatment voltage is 5 to 20 s / cm<3>, and treatment temperature is 30 to 110 DEG C. According to the invention, active groups like hydroxyl groups, carboxyl groups, epoxide groups and peroxide are creatively introduced onto the surface of the kapok fiber having undergone corona treatment, so the properties like moisture absorption, dyeing and bonding properties of the surface of the kapok fiber are effectively improved.

Owner:YANCHENG INST OF TECH

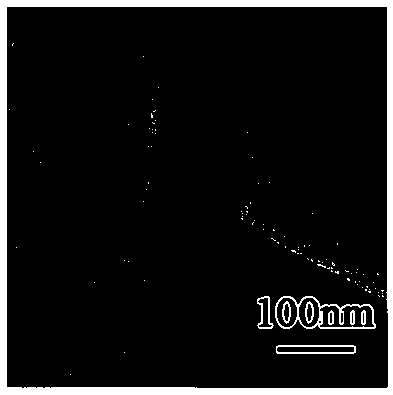

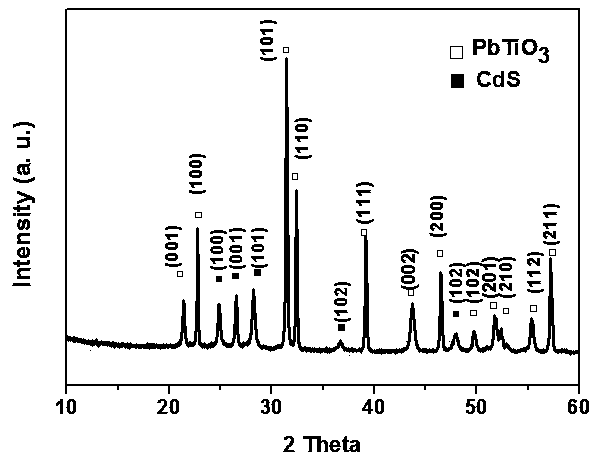

Method for preparing lead titanate nanosheet and cadmium sulfide nano-particle composite material

InactiveCN104261463AHigh purityGood dispersionMaterial nanotechnologyCadmium sulfidesDispersityChemical reaction

The invention relates to a method for preparing a lead titanate nanosheet and cadmium sulfide nano-particle composite material. According to the method, a wet chemical reaction method is adopted. The method comprises the following steps: by taking titanium dioxide as a raw material, by taking potassium hydroxide as a mineralizer, promoting crystallization, dropwise adding an aqueous solution of lead nitrate, carrying out a hydrothermal reaction, and realizing synthesis of titanium ore lead titanate monocrystalline nanosheets; by adopting an aqueous solution of cadmium chloride and thioacetamide and the synthesized perovskite lead titanate monocrystalline nanosheets as reaction materials, carrying out a secondary hydrothermal reaction, thereby synthesizing a composite nanometer structure of lead titanate nanosheets and cadmium sulfide nano-particles. The method is simple in process, easily controllable in process, pollution-free and low in cost. In addition, the prepared lead titanate nanosheet and cadmium sulfide nano-particle composite material is high in purity and high in dispersity and can provide a development basis for application of a composite material of perovskite oxides and semiconductor sulfides.

Owner:ZHEJIANG UNIV

Bladder washing fluid and preparation method and application thereof

InactiveCN106138817AReduce reoperationRelieve painAntibacterial agentsAntipyreticSide effectTherapeutic effect

The invention discloses bladder washing fluid and preparation method and application thereof. The bladder washing fluid is prepared from raw materials including, by weight, 40-48 parts of paspalum natatum, 8-16 parts of flos farfarae, 15-23 parts of fructus viticis, 3-10 parts of birthwort and 20-28 parts of Indian rorippa herb. The preparation method includes smashing and sieving the paspalum natatum, soaking with sodium thiosulfate by adding deionized water, subjecting to microwave treatment for 30-40 minutes, taking filtrate and obtaining a concentrated solution A by concentrating; smashing and sieving the fructus viticis and the birthwort, decocting by adding deionized water, taking filtrate and obtaining a concentrated solution B by concentrating; smashing and sieving flos farfarae and the Indian rorippa herb, soaking by adding absolute ethyl alcohol, subjecting to ultrasonic treatment, taking supernatant and obtaining a concentrated solution C by concentrating; mixing the concentrated solution A, the concentrated solution B and the concentrated solution C and subjected to the same to ultrasonic treatment. The bladder washing fluid has good treatment effect on cystitis patients and is short in course of treatment, quick in result and safe without side effects; security and stability after operation are increased, excessive bleeding at the position where operation is performed is reduced, and antibacterial and anti-inflammatory performance is further enhanced.

Owner:李春燕

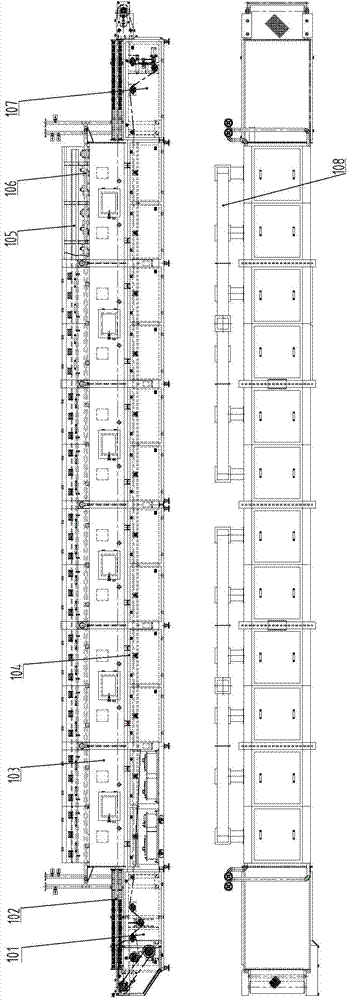

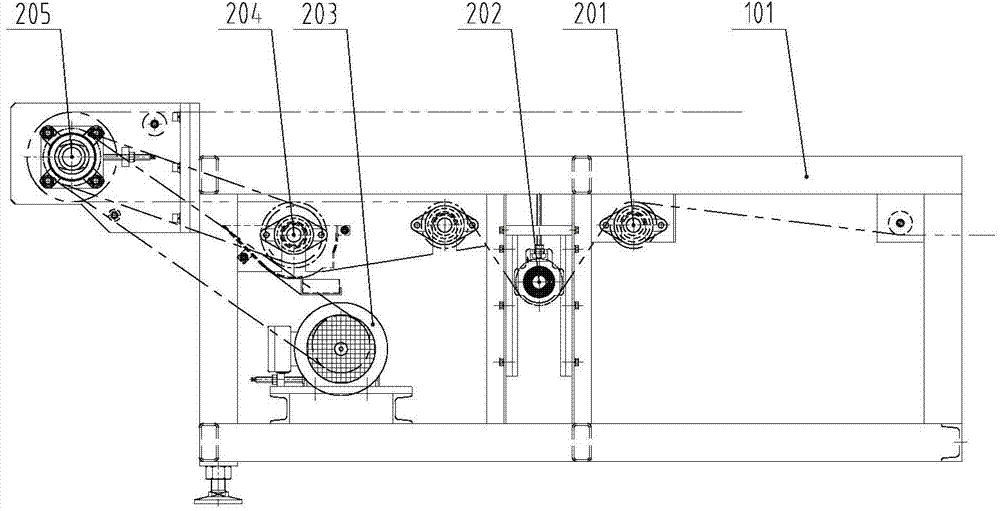

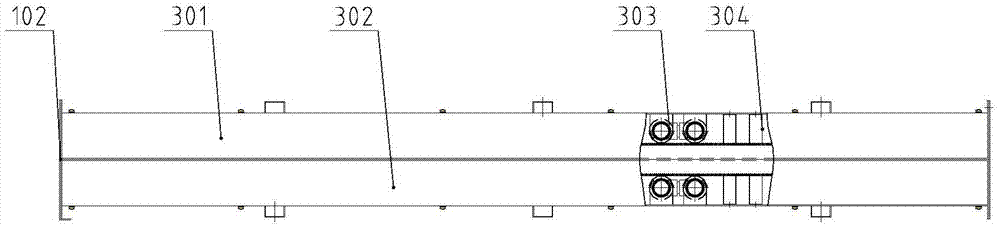

Ultrathin piece material microwave drying device

InactiveCN104748528AUniform heating temperatureNo harmDrying solid materials with heatDrying machines with progressive movementsProduction lineMicrowave

The invention discloses a ultrathin piece material microwave drying device. The ultrathin piece material microwave drying device comprises a frame, wherein a microwave inhibitor and a heating device are mounted on the frame; the microwave inhibitor is connected with the heating device; a wave guider is mounted on the heating device; and a microwave magnetron is mounted on the wave guider. The frame comprises a back frame, a middle frame and a front frame connected in sequence, wherein microwave inhibitors are respectively mounted on the back frame and the front frame; a heating device is mounted on the middle frame; and the microwave inhibitors are connected to the two ends of the heating device. The ultrathin piece material microwave drying device can be specifically applied to a rolling method slice production line to dry rolled wet slices as dry slices with stated water content, and can be applied to high-speed drying places of other ultrathin piece materials.

Owner:YICHANG BAOXING TECH IND DEVCO LTD

Synthetic method of 2-((1-benzyl-4-piperidyl)-hydroxy-methyl)-5, 6-dimethoxy-1-indanone

InactiveCN102516156AReduce difficultyReduce manufacturing costOrganic chemistrySodium methoxideBenzyl chloride

The invention discloses a synthetic method of 2-((1-benzyl-4-piperidyl)-hydroxy-methyl)-5, 6-dimethoxy-1-indanone, which comprises the following steps of: 1) synthesizing 4-methyl piperidinecarboxylate with methanol, thionyl chloride and 4-nipecotic acid, carrying out benzylation on benzyl chloride taken as benzyl and triethylamine to obtain N-benzyl-4-methyl piperidinecarboxylate; 2) reacting the N-benzyl-4-methyl piperidinecarboxylate with 5, 6-dimethoxy-1-indanone under the catalysis of sodium methoxide to obtain 2-(1-benzylpiperidine-4-carbonyl)-5, 6-dimethoxy-1-indanone; 3) carrying out reducing reaction on the 2-(1-benzylpiperidine-4-carbonyl)-5, 6-dimethoxy-1-indanone with sodium borohydride in methanol to obtain the 2-((1-benzyl-4-piperidyl)-hydroxy-methyl)-5, 6-dimethoxy-1-indanone; and the reaction formula is shown in the specifications. The synthetic method has the beneficial effects that the defects of the prior art can be overcome, the product purity can be further improved, and the production cost can be reduced.

Owner:JINAN CHENGHUI SHUANGDA CHEM

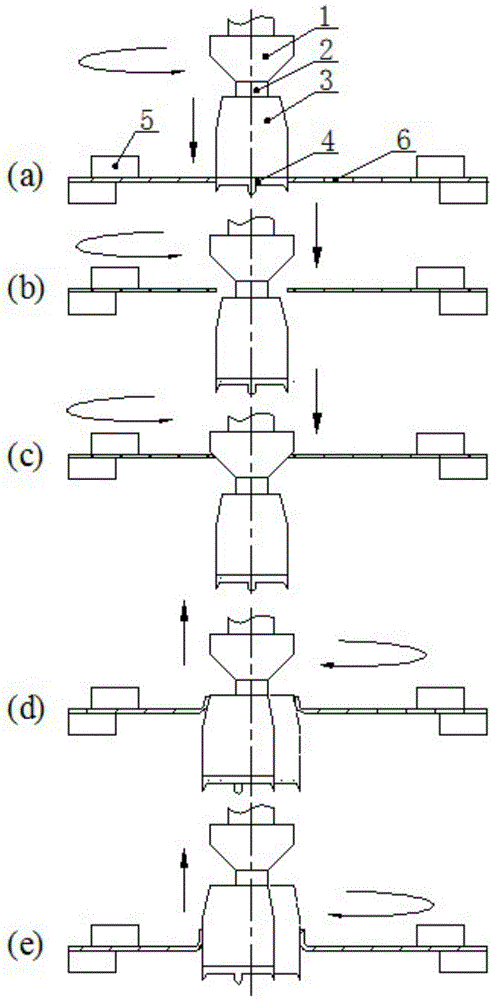

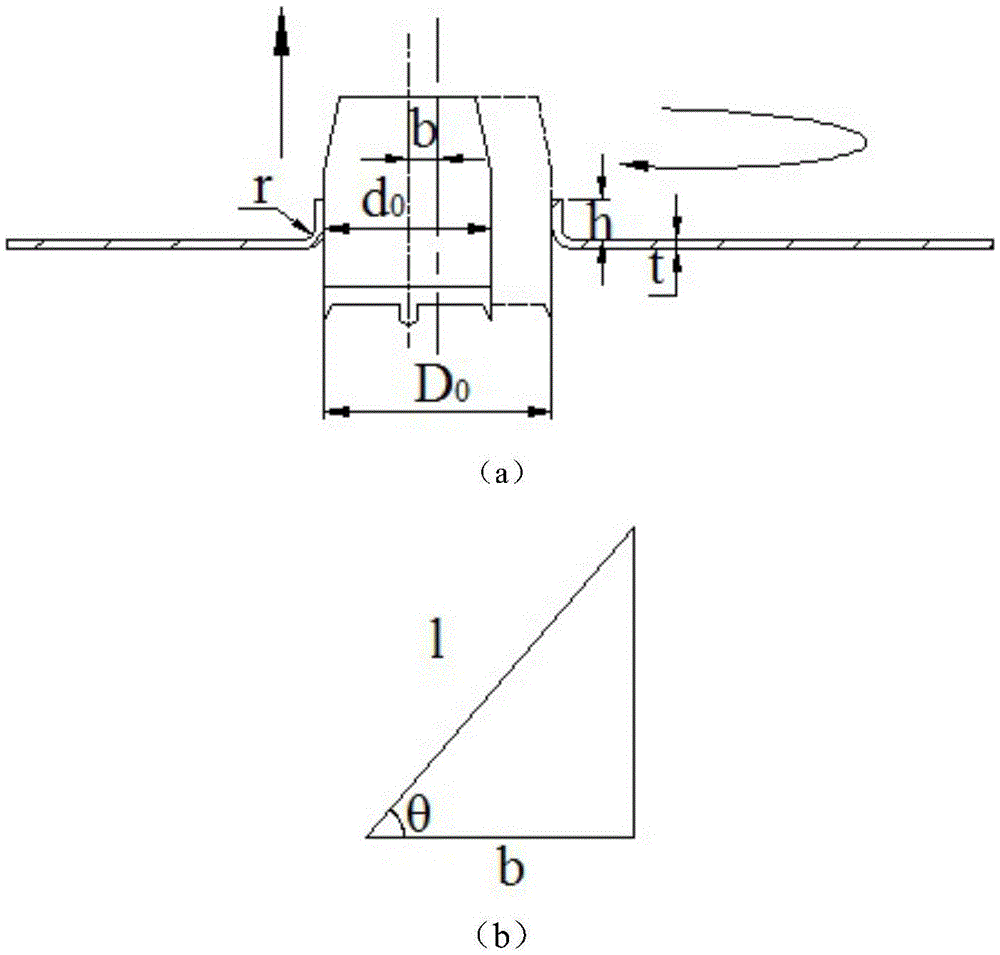

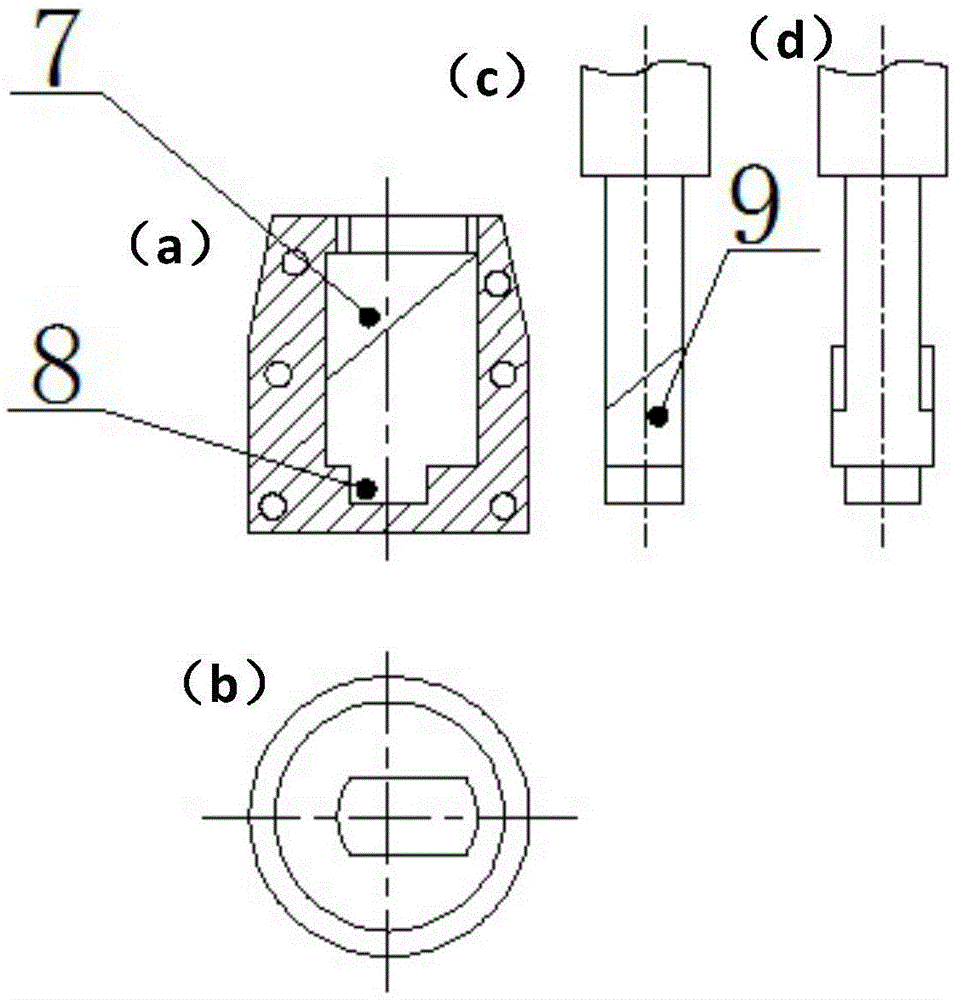

Device and method for making straight edge holes in outward-flanging mode

ActiveCN105598705ANo intervention requiredNo need to controlOther manufacturing equipments/toolsNumerical controlPipe fitting

The invention discloses a device and method for making straight edge holes in an outward-flanging mode and belongs to the technical field of local formation of sheet materials or pipe fittings. The outward hole flanging device comprises a replaceable chamfering grinding wheel, a rotating spindle, a hole flanging eccentric wheel and an opening drill bit; the replaceable chamfering grinding wheel is fixed to the spindle, and the upper end of the rotating spindle is clamped to a chuck of a drilling machine or a numerically-controlled machine tool; the hole flanging eccentric wheel is fixed to the rotating spindle, relative movement and locking with the spindle is achieved through an internal inclined slideway and a bottom groove, the appearance of the component is divided into a conical segment and a cylindrical segment, and pre hole flanging and shaping are achieved through the matching function. Compared with the prior art, four processes of hole opening, chamfering, hole flanging and shaping are completed at a time, and overall machining efficiency is improved; hole flanging is achieved through eccentric rotating motion of an eccentric wheel, the spindle only needs to rotate and move up and down, and the motion difficulty of a hole flanging tool is remarkably lowered.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Production process of brominated SBS

The invention discloses a production process of brominated SBS, and belongs to the technical field of flame retardant production, and the production process comprises the following steps: adding SBS and isobutanol into a reaction kettle, heating to 20-40 DEG C, stirring, and keeping the temperature until the materials are completely dissolved; adding sodium bromide, introducing oxidizing agent chlorine, filling lime milk at the tail end of the reaction kettle to absorb unreacted chlorine in the reaction kettle, and heating to 60-75 DEG C and then stopping heating; cooling to 20 DEG C, adding acatalyst, and continuously heating to 75 DEG C to react for 1 hour, wherein the catalyst being tin tetrachloride and ferric trichloride; and cooling to room temperature, adding peroxide and alkali metal alkoxide into the material liquid after the reaction is finished, heating to 30-40 DEG C, keeping the temperature for 2 hours, filtering, washing, removing impurities, and drying to obtain the target product brominated SBS, wherein the peroxide is hydrogen peroxide, and the alkali metal alkoxide is sodium methoxide. The preparation of the brominated SBS is realized by adopting a direct bromination method, the reaction is mild, the bromine content, the yield and the thermal stability of the brominated SBS are improved, and the use requirements are met.

Owner:山东东信新材料科技股份有限公司

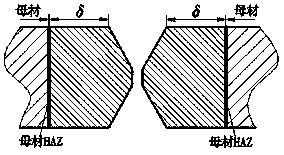

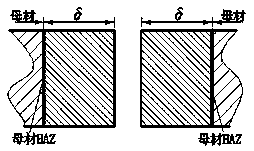

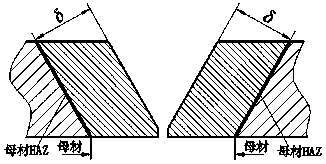

Composite welding method for preventing coarsening of base material HAZ crystal grains

The invention discloses a composite welding method for preventing coarsening of base material HAZ crystal grains. The method includes the steps that (1) a plurality of layers of metal wires with required components are formed on a to-be-welded surface of a workpiece, namely a base material through build-up welding, so that a build-up welded layer with a certain thickness is formed, wherein the thickness of the build-up welded layer is larger than the before-welding thickness (delta); (2) after build-up welding, a required groove shape and size are machined in the build-up welded layer; and (3)filling welding is carried out through a conventional welding method to fill a groove, and the build-up welded layer with an initial thickness (alpha) is melted in the filling welding process, so that the thickness of the grooved build-up welded layer is reduced from the before-welding thickness (delta) before filling welding to the after-welding thickness (theta) after filling welding, meanwhile, a heat affected zone with the width (beta) formed by filling welding is formed on the remaining build-up welded layer with the after-welding thickness (theta), and the before-welding thickness (delta), the initial thickness (alpha) and the width (beta) satisfy the condition that delta minus alpha is lager than beta or theta is larger than beta.

Owner:LANZHOU JIAOTONG UNIV

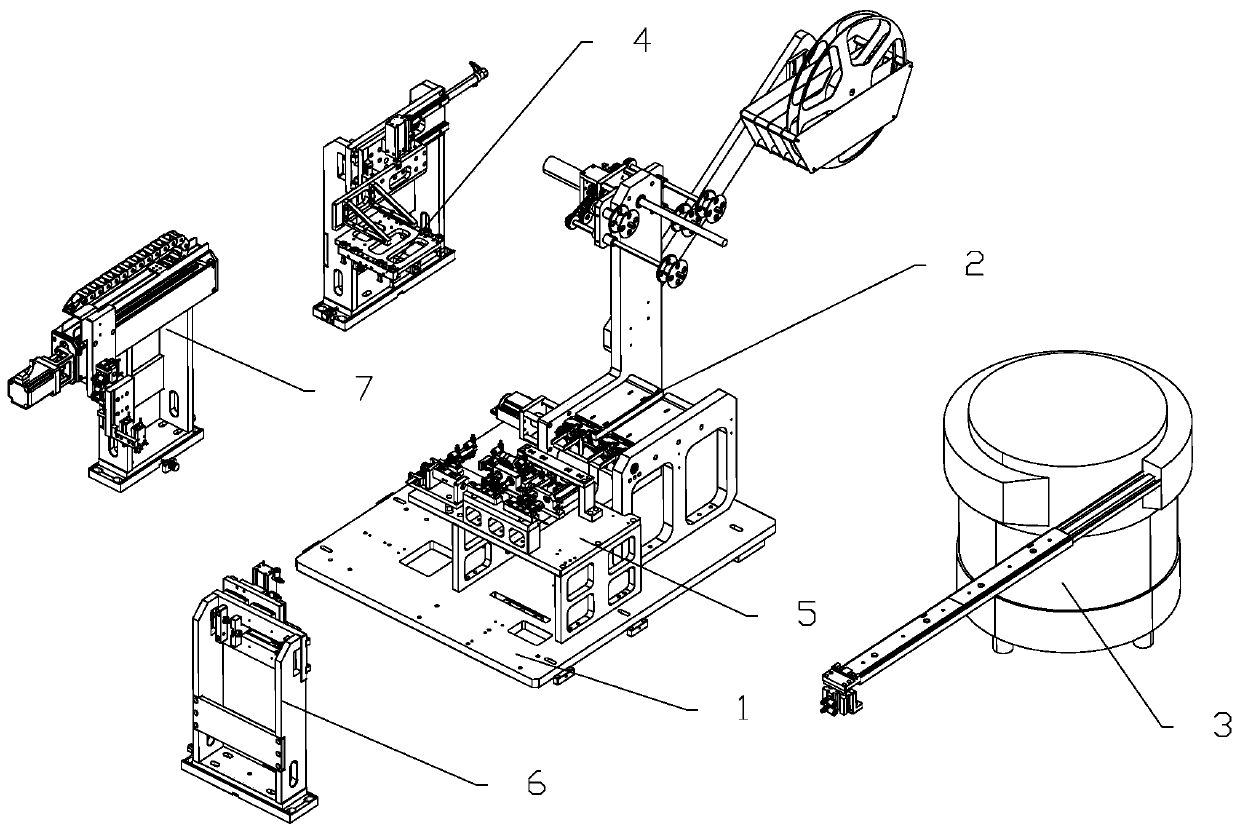

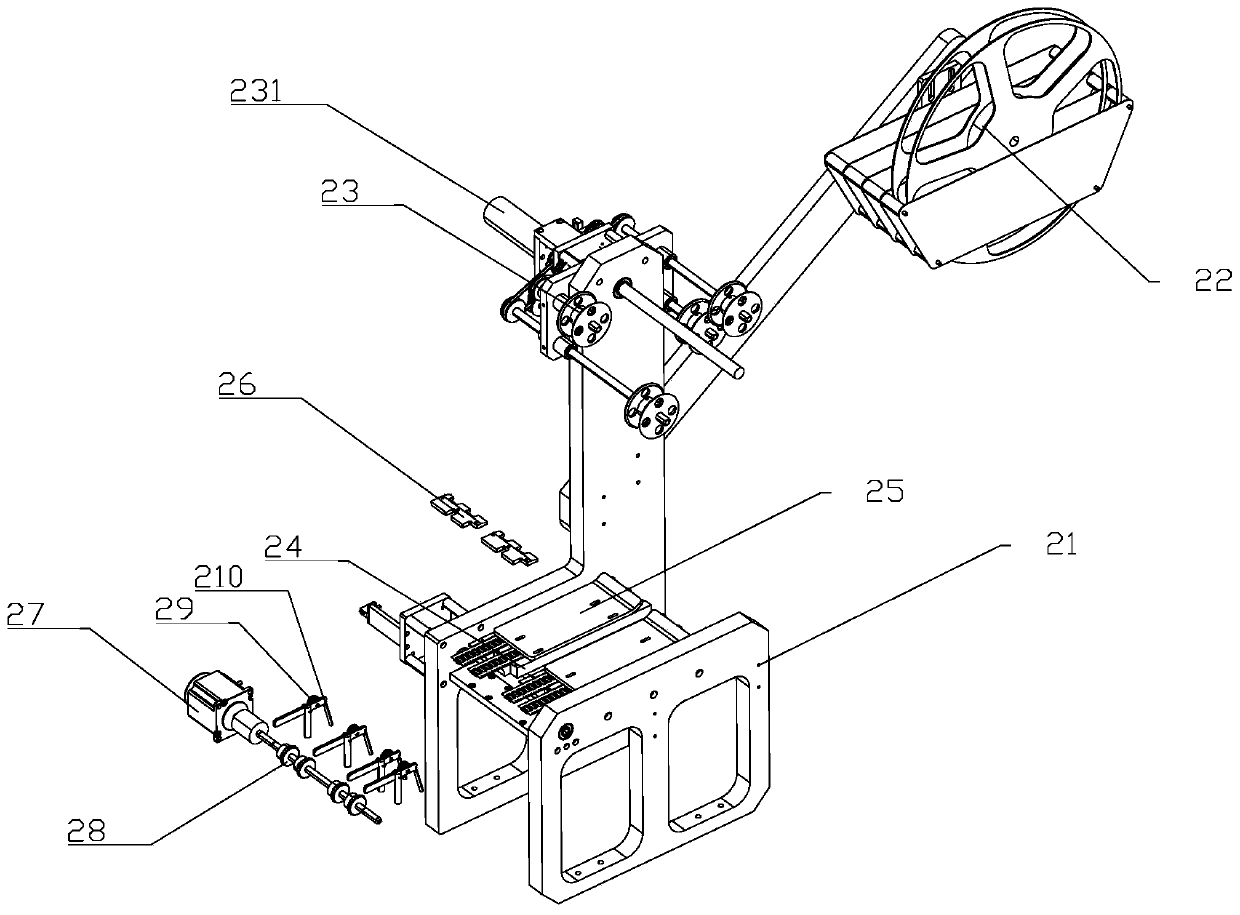

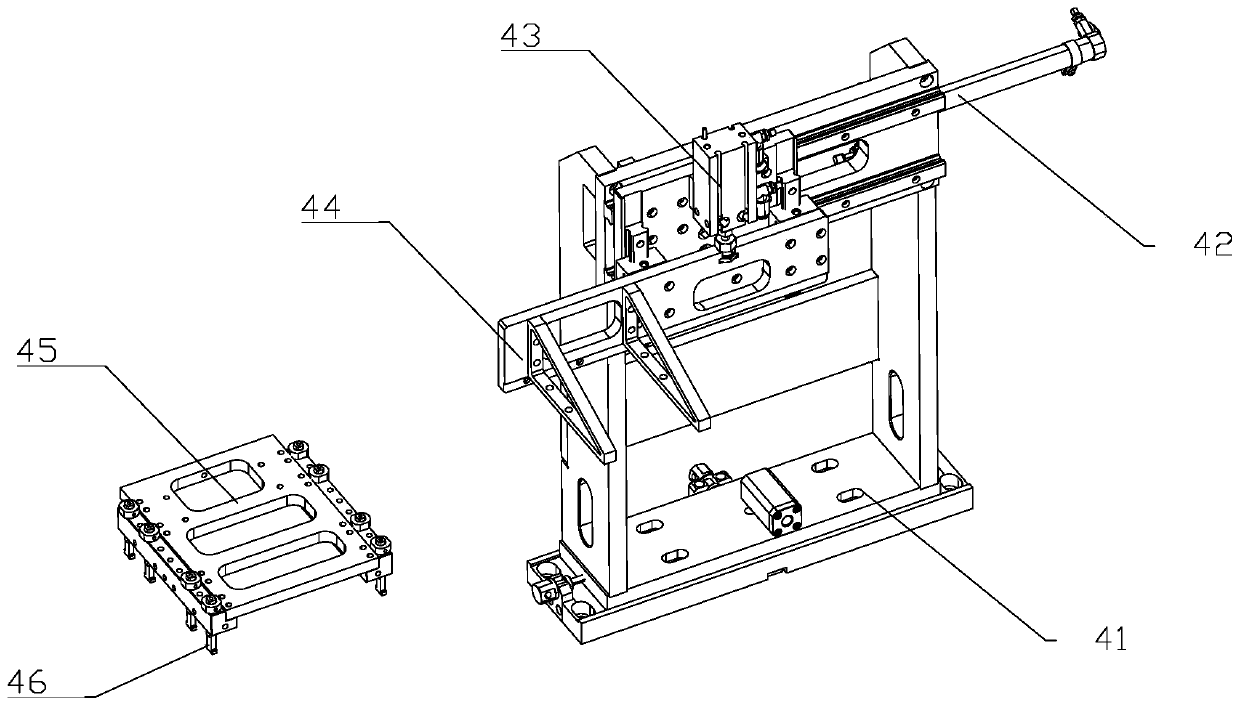

Production device and method for electronic cigarette foam

InactiveCN110757120AStable and reliable feedingAvoid mistakesMetal working apparatusProcess engineeringElectronic cigarette

The invention relates to the technical field of electronic cigarette production and discloses a production device and method for electronic cigarette foam. The production device comprises a mounting plate, a foam feeding mechanism, a housing feeding device, a foam carrying mechanism, a foam loading mechanism, a housing carrying mechanism and a discharging carrying mechanism, wherein the foam feeding mechanism, the housing feeding device, the foam carrying mechanism, the foam loading mechanism, the housing carrying mechanism and the discharging carrying mechanism are arranged on the mounting plate; the foam loading mechanism is positioned in the middle of the mounting plate; the foam feeding mechanism is positioned on the side of the foam loading mechanism; the foam carrying mechanism is connected with the foam feeding mechanism and the foam loading mechanism; the housing carrying mechanism is connected with the housing feeding device and the foam loading mechanism; and the dischargingcarrying mechanism is positioned on the discharging side of the foam loading mechanism. The foam feeding mechanism is used for feeding in a carrier tape mode, so that feeding is reliable and stable; and the foam loading mechanism is used for assembling the foam at the upper end and the lower end at the same time, so that the production efficiency is improved, and the production success rate is higher.

Owner:徐新建

Medical supercritical carbon dioxide sterilization system

InactiveCN113730632AEasy to grabSave manpower and timeLavatory sanitoryChemicalsEngineeringPlastic film

The invention discloses a medical supercritical carbon dioxide sterilization system. The medical supercritical carbon dioxide sterilization system comprises a machine shell; five placement cavities communicated with the outside are formed in the machine shell; a disinfection cavity is formed in the right end wall of each placement cavity; a detection cavity is formed in the rear end wall of each disinfection cavity; and a self-locking cavity is formed in the upper end wall of each detection cavity. The sterilization system is provided with a grabbing mechanism, a storage mechanism and an execution mechanism; by means of a support arranged on the grabbing mechanism, a push rod can be pressed down, a tool protrudes, a clamping block and an active clamping block can grab the tool conveniently, the whole device can be fixed through the support, labor time is saved, the safety of people is improved, secondary pollution caused by manual participation is reduced, manual supervision and control are not needed, and efficiency is improved; and by means of an arranged pressure sensor, the storage amount in a plastic film pipe can be judged by making contact with the plastic film pipe through the pressure sensor, so that a sucking pump and a relay are controlled, inflation is completed, supplementation of the plastic film pipe is completed, the device can also be used for disinfecting objects placed in the placement cavity, and manual supervision and starting are not needed.

Owner:黄鑫

Sulfur element analysis auxiliary treatment device and method for eliminating influence of high content nitrogen element

PendingCN109211785AEliminate the effects ofTraits have no effectFluorescence/phosphorescenceElement analysisSulfur

The invention provides a sulfur elements analysis auxiliary treatment device and a method for eliminating influences of high content nitrogen elements. The device comprises a three-way reaction tube.A first inlet of the three-way reaction tube is connected with an ozone supply source. A sample gas inlet pipeline is connected with a second inlet of the three-way reaction tube, and is used for accessing sample gas subjected to high temperature catalytic oxidation. An outlet of the three-way reaction tube is connected with a sample gas outlet pipeline, and is used for feeding the sample gas intoa sulfur element detection device. The ozone entering the three-way reaction tube from the first inlet can react with the sample gas entering the three-way reaction tube from the second inlet, and the reacted sample gas enters a sulfur element detection link through the outlet of the three-way reaction tube, so that influences on the detection result of the nitrogen elements can be eliminated.

Owner:北京诺德泰科仪器仪表有限公司

Automatic traffic dispersion equipment for pedestrian flow at intersection

InactiveCN110969878AFit closelySimple structureArrangements for variable traffic instructionsStructural engineeringMachine

The invention discloses automatic traffic dispersion equipment for pedestrian flow at an intersection. The automatic traffic dispersion equipment comprises a machine body comprising a moving cavity, amoving mechanism is arranged in the moving cavity, a first rotating shaft is arranged on the upper side of the moving cavity, three rotating wheels are rotationally arranged on the first rotating shaft, a first connecting rod is fixedly arranged between the rotating wheels, a first open groove is formed in the bottom end wall of the moving cavity, a second connecting rod is fixedly arranged in the first open groove, and a third connecting rod is rotationally arranged on the second connecting rod. The automatic traffic dispersion equipment is simple in structure and easy and convenient to operate, pedestrian flow can be accurately switched according to the time of the traffic light in a full-automatic mode, pedestrians can be released orderly in batches through the automatic traffic dispersion equipment, the occurrence rate of accidents when the pedestrian flow is large is reduced, all mechanisms of the automatic traffic dispersion equipment are tightly matched, the integration degreeis high, control is not needed, and convenience and rapidness are achieved.

Owner:SHENGZHOU MIXIANG ROAD FACILITIES CO LTD

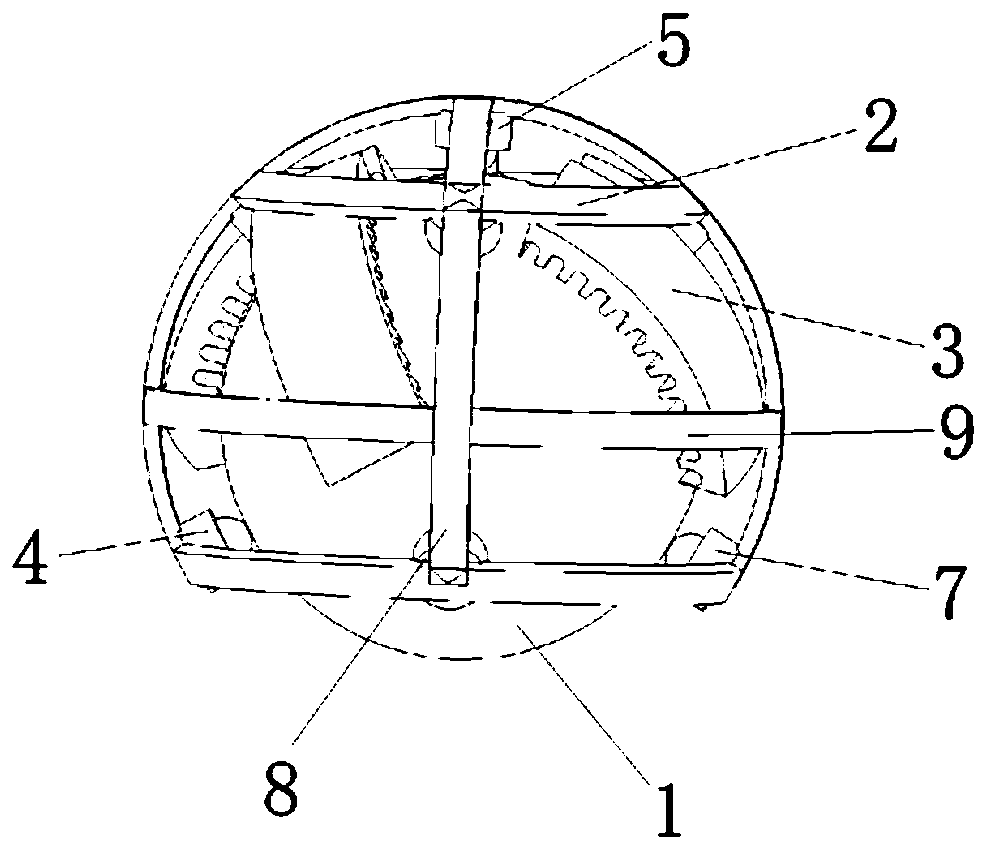

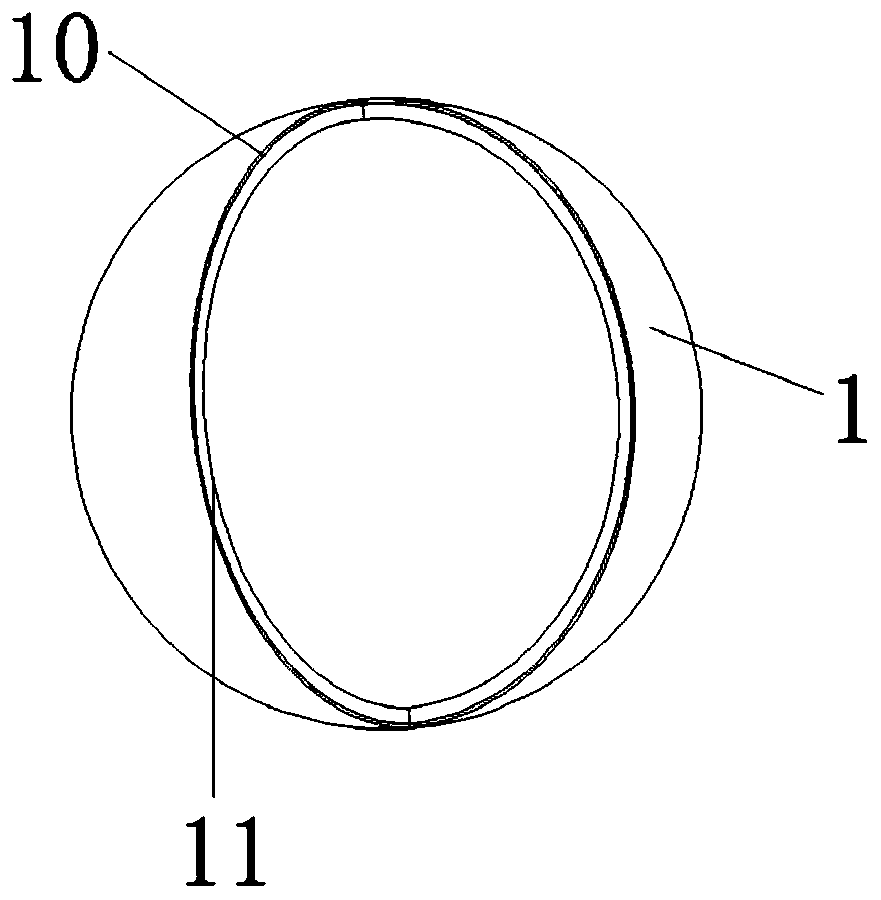

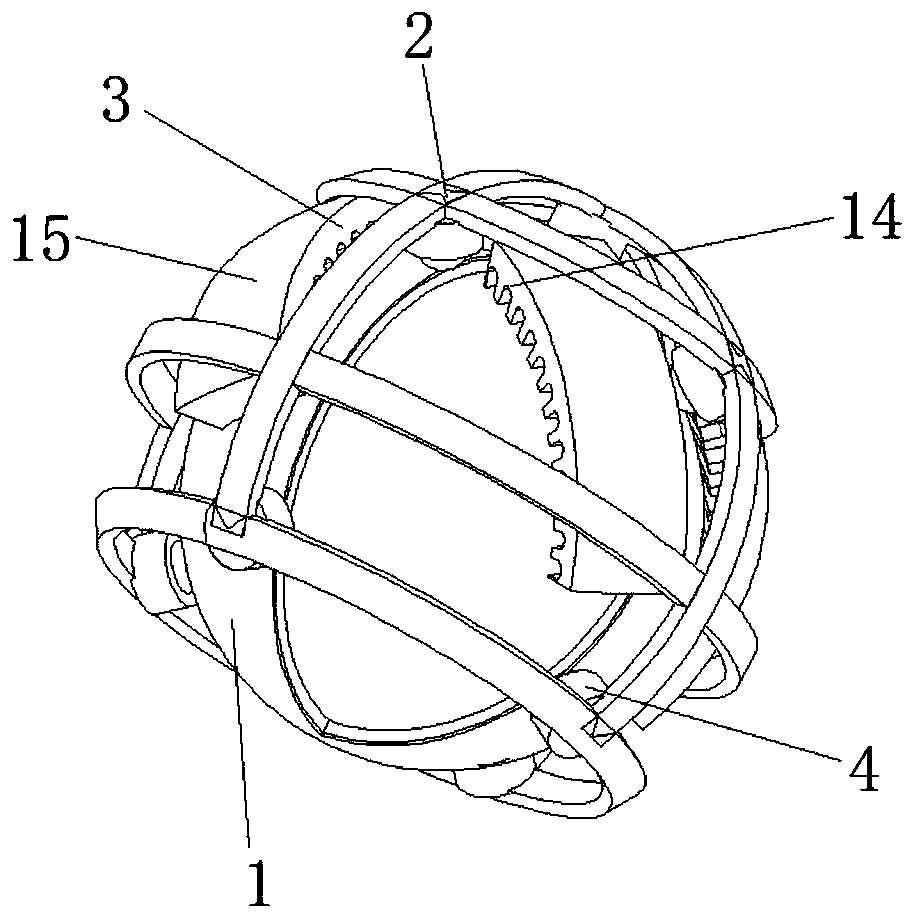

Spherical induction motor without output shaft

InactiveCN110391724AChange outputNo need to controlMagnetic circuit rotating partsMagnetic circuit stationary partsLongitudeBarycentric coordinates

The invention discloses a spherical induction motor without an output shaft. The induction motor includes a spherical shell, a stator support and stator units fixed on the stator support; the stator units are located between the stator support and the spherical shell; bull-eye bearings are arranged between the stator support and the spherical shell, and include arctic bearings and weft ring bearing sets, and / or Antarctic bearings; all the bull-eye bearings are in contact with the spherical shell; the stator support includes longitude rings arranged in a longitude direction and weft rings arranged in a weft direction; the weft ring bearing sets include multiple bull-eye bearings fixed on the same weft rings; each stator unit is at an included angle with longitudes; and the centers of gravity of the stator units are located on the same weft and below the equator of the stator support. The induction motor is simple in structure and control without extra power transmission equipment; and the induction motor can be applied to direct driving occasions of robot driving, detection device driving and spherical cameras.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com