Driving device for swinging grinding head

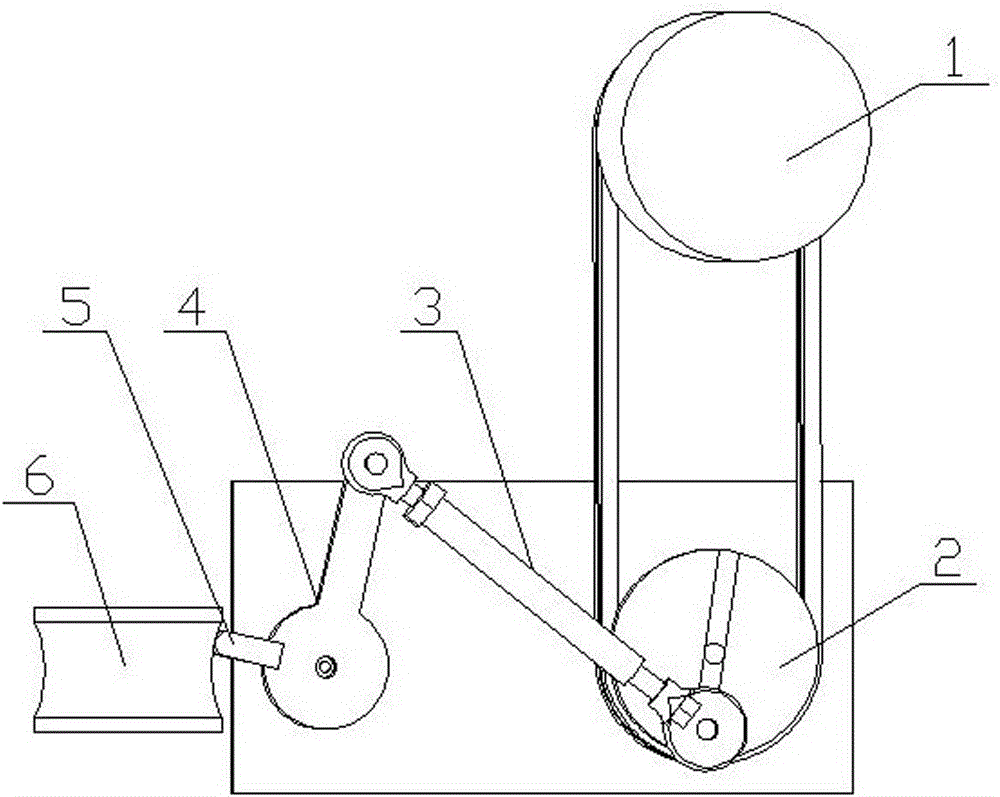

A technology of driving device and grinding head, which is applied in the direction of grinding driving device, grinding machine parts, grinding/polishing equipment, etc. It can solve the problems of time-consuming maintenance, great influence on workpiece machining accuracy, and affecting motor life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

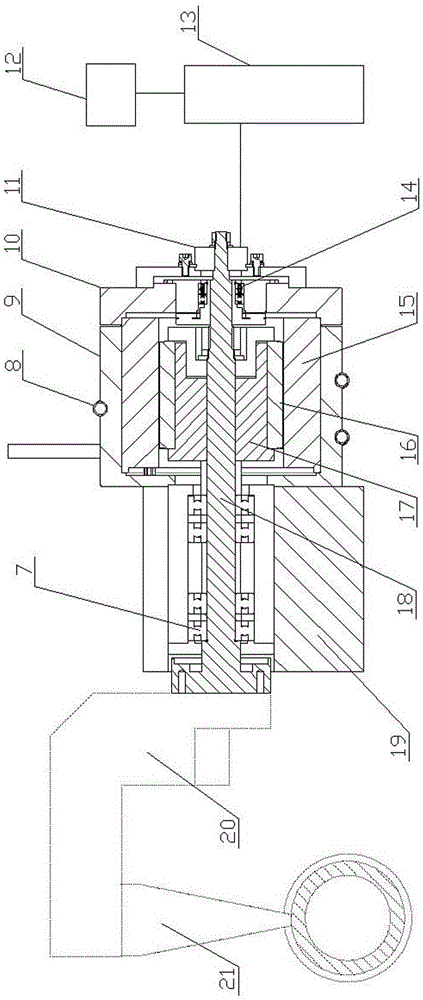

[0025] Such as figure 2 As shown, the swing grinding head driving device of the present invention includes a casing 9, which is cylindrical, with one end closed and one end open, and a cover plate 10 is arranged on the open end, the closed end of the casing 9 and the cover The plates 10 each have a central hole. There is a main shaft 18 in the casing 9, and the main shaft 18 passes through the closed end of the casing 9 and the central hole of the cover plate 10 respectively, and there is a gap between the main shaft 18 and the two central holes. A motor stator 15 is fixed on the inner wall of the casing 9 , and a motor rotor 16 is fixed on the section of the main shaft 18 in the casing 9 . The outer side of the closed end of the casing 9 is fixed with a support seat 19, the section of the main shaft 18 on the outside of the closed end of the casing 9 passes through the support seat 19, and the main shaft 18 and the support seat 19 are rotationally fitted by the bearing 7, a...

Embodiment 2

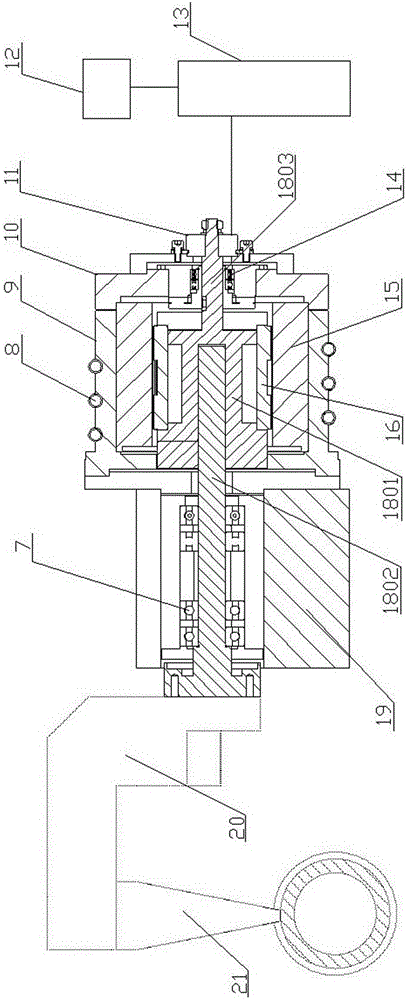

[0029] Such as image 3 As shown, the swing grinding head driving device of the present invention includes a casing 9, which is cylindrical, with one end closed and one end open, and a cover plate 10 is arranged on the open end, the closed end of the casing 9 and the cover The plates 10 each have a central hole. There is a main shaft 18 in the casing 9, and the main shaft 18 passes through the closed end of the casing 9 and the central hole of the cover plate 10 respectively, and there is a gap between the main shaft 18 and the two central holes. A motor stator 15 is fixed on the inner wall of the casing 9 , and a motor rotor 16 is fixed on the section of the main shaft 18 in the casing 9 . The outer side of the closed end of the casing 9 is fixed with a support seat 19, the section of the main shaft 18 on the outside of the closed end of the casing 9 passes through the support seat 19, and the main shaft 18 and the support seat 19 are rotationally fitted by the bearing 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com