Windmill flexible positioning device for white car body welding production line

A welding production line and flexible positioning technology, which is applied to auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of complex structure of multi-axis servo flexible positioning unit, inability to change the diameter of positioning holes in the body, and the inability to produce multiple models. , to achieve the effect of avoiding multiple neck winding, easy control and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

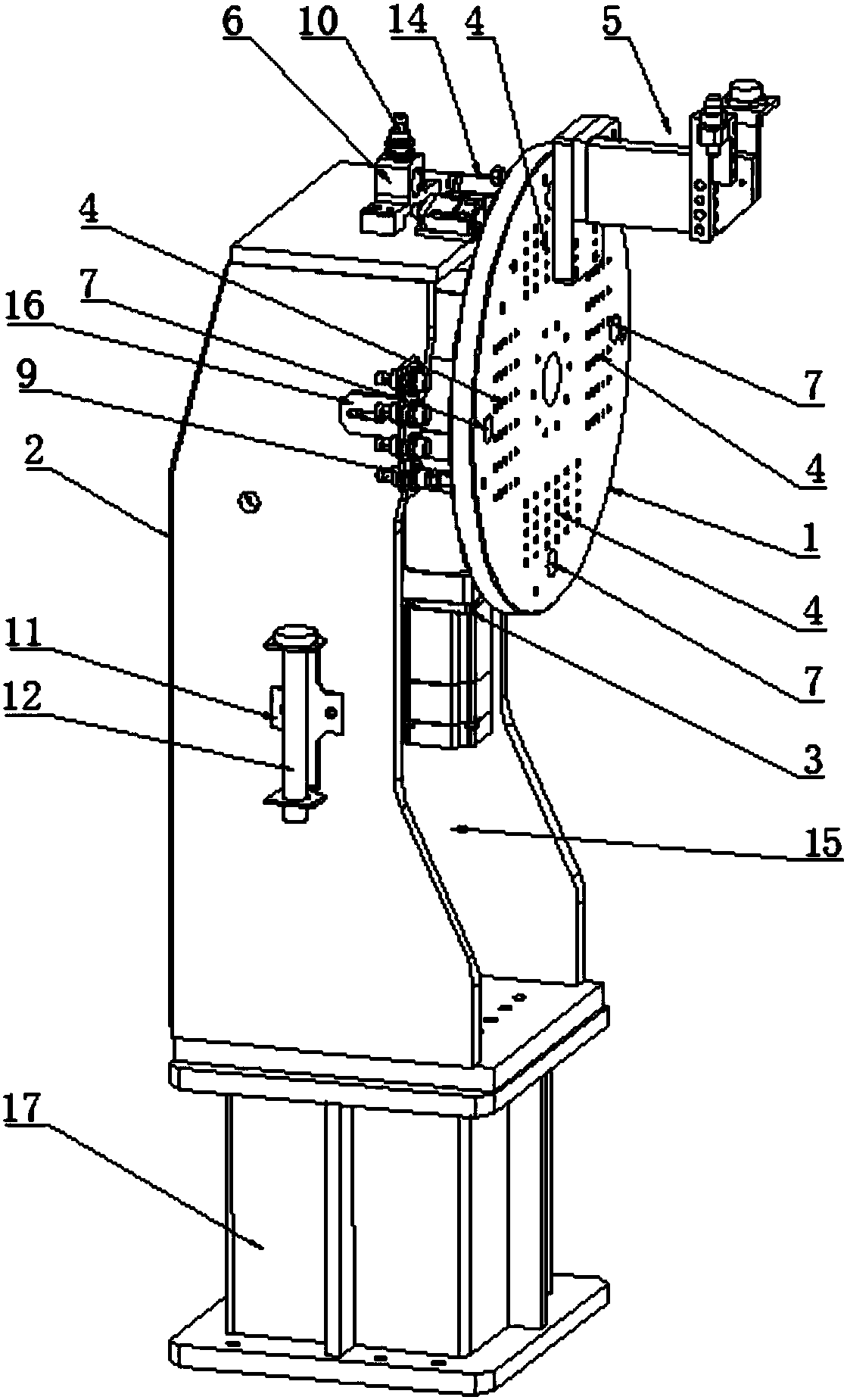

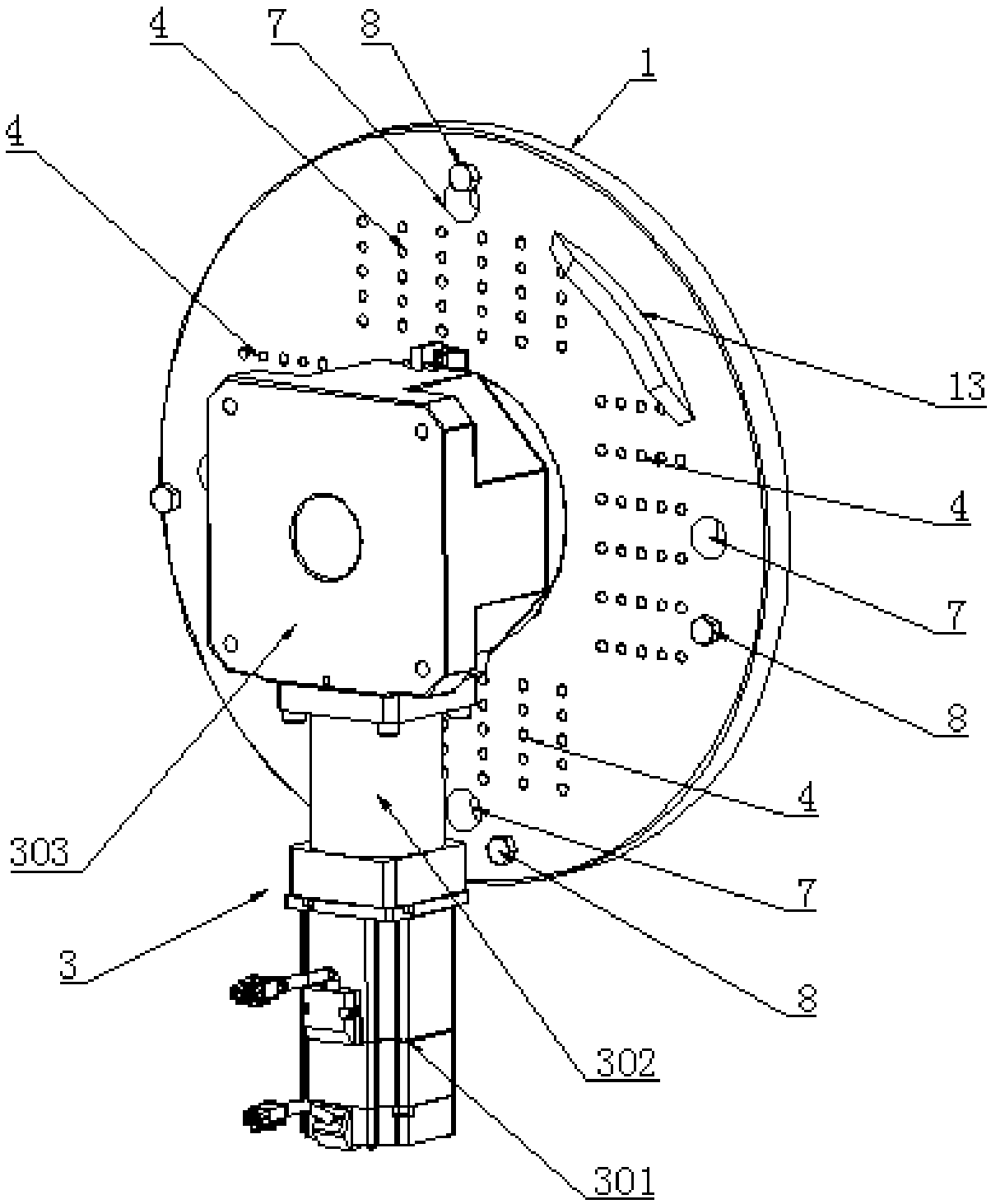

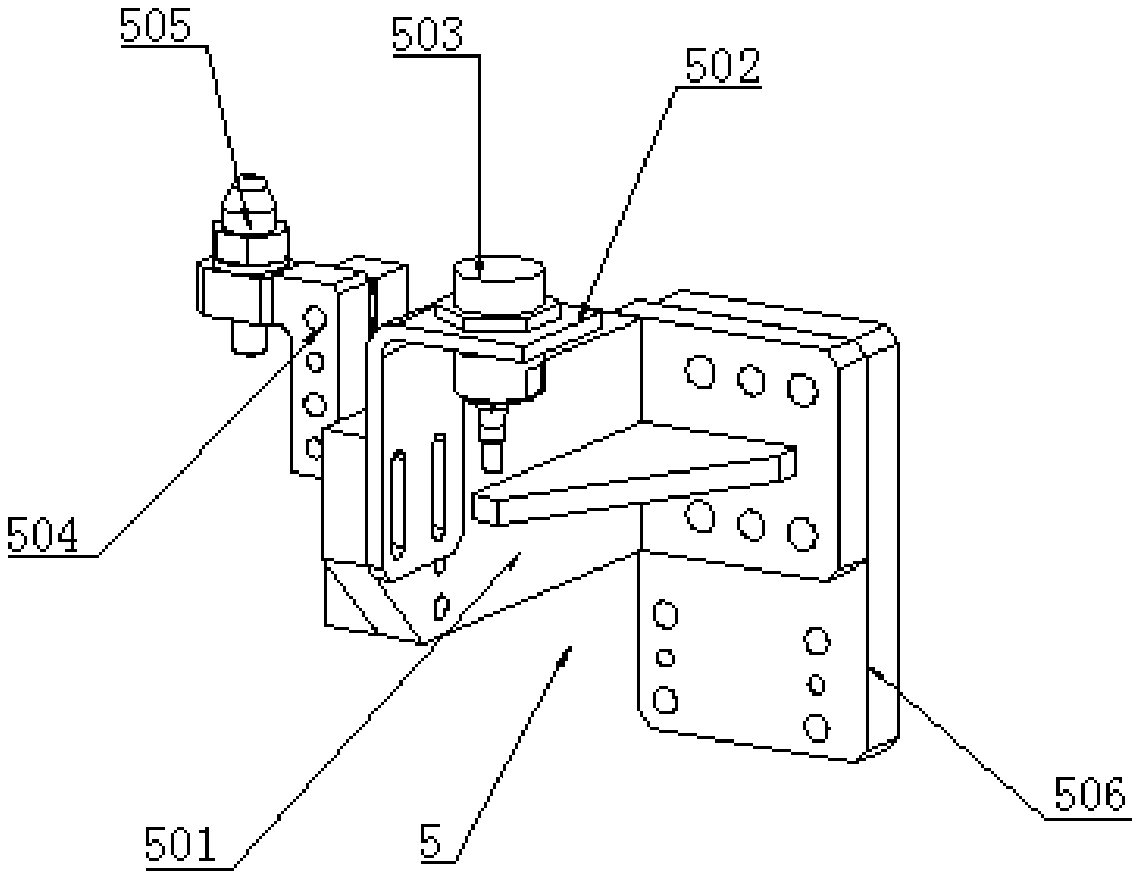

[0022] The specific embodiment of the present invention is like this: as Figure 1-3 As shown, a windmill flexible positioning device used in the body-in-white welding production line includes a turntable frame 2, a base 17 is provided at the bottom of the turntable frame 2, and the positioning device is stably supported by the base 17, and one side of the turntable frame 2 is provided There is a vertically arranged and rotatable windmill turntable 1, and the turntable frame 2 is provided with a driving device 3 for driving the windmill turntable 1 to rotate. The disk body of the windmill turntable 1 is provided with a plurality of positioning stations 4 evenly arranged, and the positioning stations 4 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com