Composite welding method for preventing coarsening of base material HAZ crystal grains

A composite welding and base metal technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of long residence time at high temperature, coarsening of joint mechanical properties, and decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

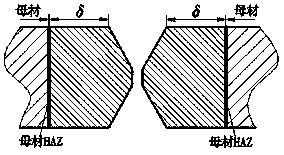

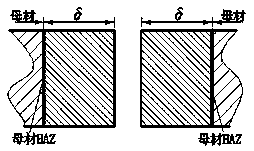

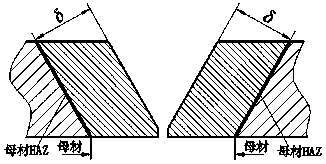

[0010] The groove shape of the workpiece surfacing layer of the present invention (with surfacing layer) and the structure of the corresponding composite welded joint are as follows: Figure 1~Figure 8 As shown, the present invention is a composite welding method in which the HAZ grains of the parent material do not coarsen, and the steps are:

[0011] (1) Using argon tungsten arc spot welding process and reasonable welding parameters, several layers of metal wire with the required composition are surfacing on the workpiece, that is, the surface of the base metal to be welded, so as to form a certain thickness of surfacing layer. Layer thickness > Thickness before welding δ ;

[0012] (2) After the surfacing welding is completed, process the required groove shape and size on the surfacing layer;

[0013] (3) Then use the conventional welding method for filling welding to fill the groove, and there will be an initial thickness during the filling welding process α The surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com