Microstructure and properties control method of near-α-type titanium alloy under isothermal local loading transition zone

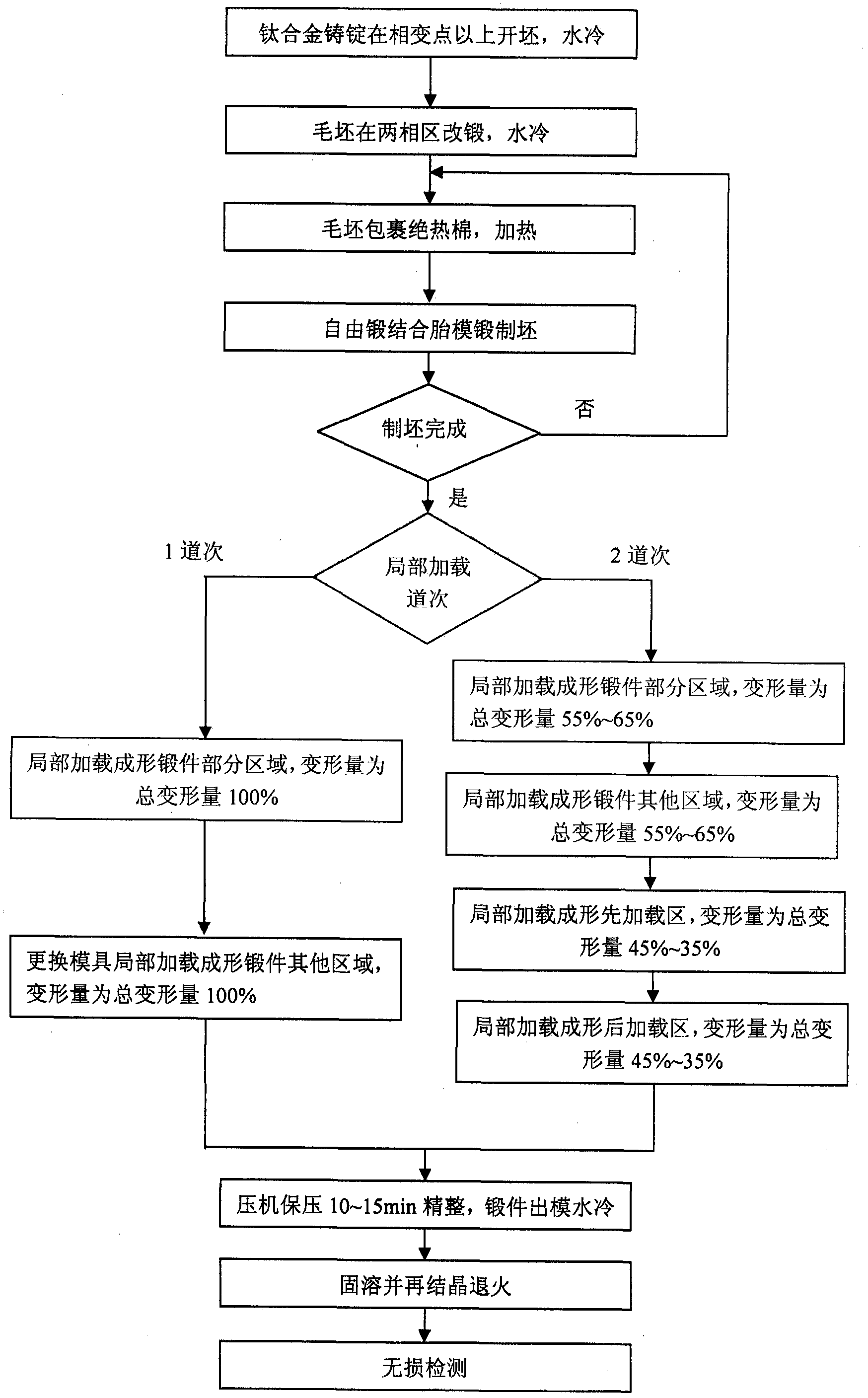

A technology of isothermal local loading and microstructure properties, applied in the field of thermal processing, can solve problems such as microstructure, reduction, and mechanical properties of uneven transition zones, and achieve the effect of no grain coarsening and stable evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment is a TA15 titanium alloy integral rib member produced by a steel company. It is formed by an isothermal local loading mold consisting of an inner mold and an outer mold. The inner mold forms the middle part of the workpiece, and the outer mold forms both sides of the workpiece. The position corresponding to the boundary line of the inner mold and the outer mold and its adjacent area is the transition zone. The TA15 titanium alloy ingot is melted by three vacuum consumable arcs, and the phase transition point T β It is 990°C. The specific operation is as follows:

[0025] The first step is to forge the blank. TA15 titanium alloy ingots are heated to T in a resistance furnace β +100°C, heat preservation for 2 hours, upsetting and drawing on the fast forging machine, the deformation amount is 50% to 60%, water cooling after forging; then the blank is heated to T in the resistance furnace β -40℃, heat preservation for 1.5h, repeated upsetting and drawing...

Embodiment 2

[0034] This embodiment is a TA15 titanium alloy integral rib member produced by a steel company. It is formed by an isothermal local loading mold consisting of an inner mold and an outer mold. The inner mold forms the middle part of the workpiece, and the outer mold forms both sides of the workpiece. The position corresponding to the boundary line of the inner mold and the outer mold and its adjacent area is the transition zone. The TA15 titanium alloy ingot is melted by three vacuum consumable arcs, and the phase transition point T β It is 990°C. The specific operation is as follows:

[0035] The first step is to forge the blank. TA15 titanium alloy ingots are heated to T in a resistance furnace β +50°C, heat preservation for 3 hours, upsetting and drawing on the fast forging machine, the deformation amount is 50% to 60%, water cooling after forging; then the blank is heated to T in the resistance furnace β -40℃, heat preservation for 1.5h, repeated upsetting and drawing ...

Embodiment 3

[0044] This embodiment is a TA15 titanium alloy integral rib member produced by a steel company. It is formed by an isothermal local loading mold consisting of three block molds on the left, middle and right. The middle module forms the middle part of the workpiece, and the left and right modules move simultaneously. On both sides of the formed workpiece, the position corresponding to the boundary line between the middle module and the left and right modules on the workpiece and its adjacent area are transition zones. The TA15 titanium alloy ingot is melted by three vacuum consumable arcs, and the phase transition point T β It is 990°C. The specific operation is as follows:

[0045] The first step is to forge the blank. The ingot is heated in a resistance furnace to T β +50°C, heat preservation for 3 hours, upsetting and drawing on the fast forging machine, the deformation amount is 50% to 60%, water cooling after forging; then the blank is heated to T in the resistance fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com