Method for preparing lead titanate nanosheet and cadmium sulfide nano-particle composite material

A nanoparticle and composite material technology, applied in the direction of cadmium sulfide, titanium compounds, chemical instruments and methods, etc., can solve problems such as no relevant reports, and achieve the effect of simple process, no pollution and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

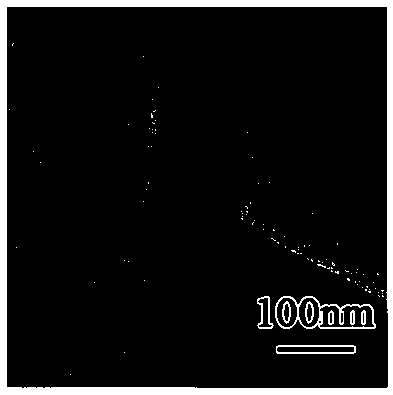

Image

Examples

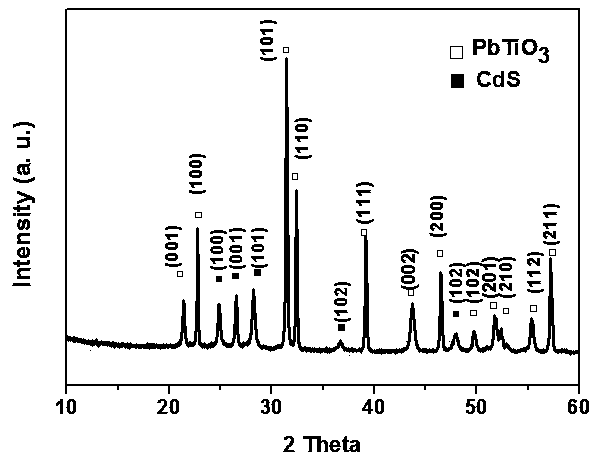

Embodiment 1

[0017] 1) Dissolve titanium dioxide in 6mol / L potassium hydroxide aqueous solution to adjust Ti 4+ The ion concentration is 0.1mol / L;

[0018] 2) Configure a 0.2mol / L lead nitrate aqueous solution, and add the Ti prepared in step 1) dropwise under stirring 4+ an aqueous solution, adjusting the lead-titanium molar ratio to 2.0, and stirring for 20 minutes to obtain an oxyhydroxide precipitation mixture of titanium and lead.

[0019] 3) Add the mixed liquid in step 2) into the inner tank of the reactor, adjust its volume to 80% of the inner tank volume of the reactor with deionized water, stir for 5 minutes, and place the inner tank of the reactor with the reaction materials in the reactor , airtight, reacted at 200°C for 12 hours, placed in the air to cool down to room temperature naturally, took out the reaction product, washed it repeatedly with 1% nitric acid and deionized water for 3 times, filtered, and dried to obtain Powdered perovskite lead titanate nanosheets;

[00...

Embodiment 2

[0023] 1) Dissolve titanium dioxide in 6 mol / L potassium hydroxide aqueous solution, adjust Ti 4+ The ion concentration is 0.2mol / L;

[0024] 2) Configure a 0.1mol / L lead nitrate aqueous solution, and add the Ti prepared in step 1) dropwise under stirring 4+ an aqueous solution, adjusting the lead-titanium molar ratio to 0.5, and stirring for 30 minutes to obtain an oxyhydroxide precipitation mixture of titanium and lead.

[0025] 3) Add the mixed solution of step 2) into the inner tank of the reactor, adjust its volume to 80% of the inner tank volume of the reactor with deionized water, stir for 3 minutes, and place the inner tank of the reactor with the reaction materials in the reactor in airtight, placed at 200°C for 8 hours, then placed in the air to cool down to room temperature naturally, the reaction product was taken out, washed repeatedly with 1% nitric acid and deionized water for 5 times, filtered, and dried. Obtain powdered perovskite lead titanate nanosheets; ...

Embodiment 3

[0029] 1) Dissolve titanium dioxide in 6mol / L potassium hydroxide aqueous solution to adjust Ti 4+ The ion concentration is 0.2mol / L;

[0030] 2) Configure a 0.3mol / L lead nitrate aqueous solution, and add the Ti prepared in step 1) dropwise under stirring 4+ an aqueous solution, adjusting the molar ratio of lead to titanium to 1.5, and stirring for 30 minutes to obtain a mixed solution of titanium and lead oxyhydroxide precipitation.

[0031] 3) Add the mixed liquid in step 2) into the inner tank of the reactor, adjust its volume to 80% of the inner tank volume of the reactor with deionized water, stir for 10 minutes, and place the inner tank of the reactor with the reaction materials in the reactor , airtight, placed at 200 ° C for 10 hours, placed in the air to cool down to room temperature naturally, the reaction product was taken out, washed repeatedly with 1% nitric acid and deionized water for 4 times, filtered, and dried. Obtain powdered perovskite lead titanate nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com