Spherical induction motor without output shaft

An induction motor with no output technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve problems such as angle range limitation, and achieve the effect of simple control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

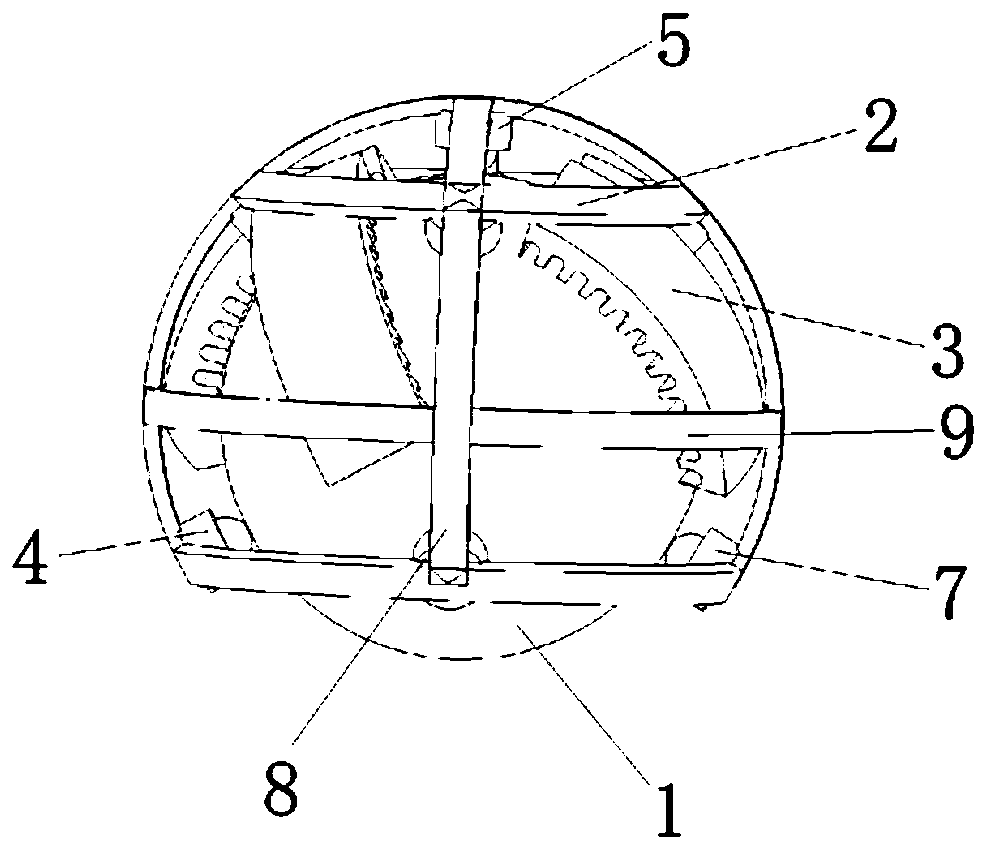

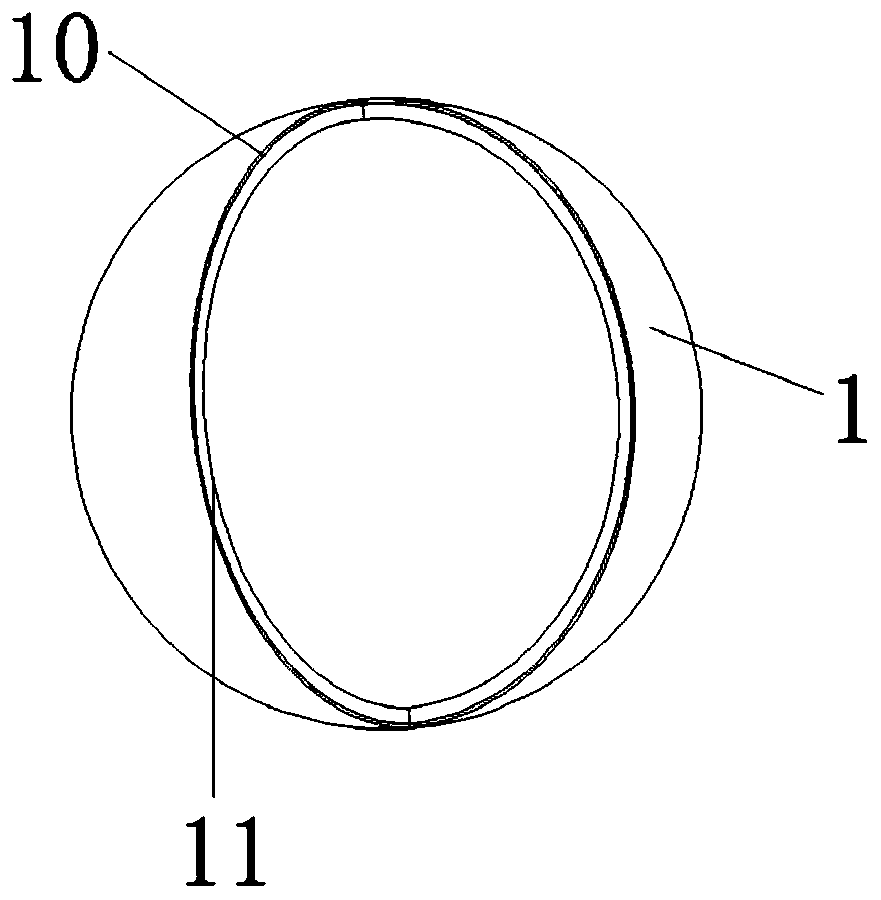

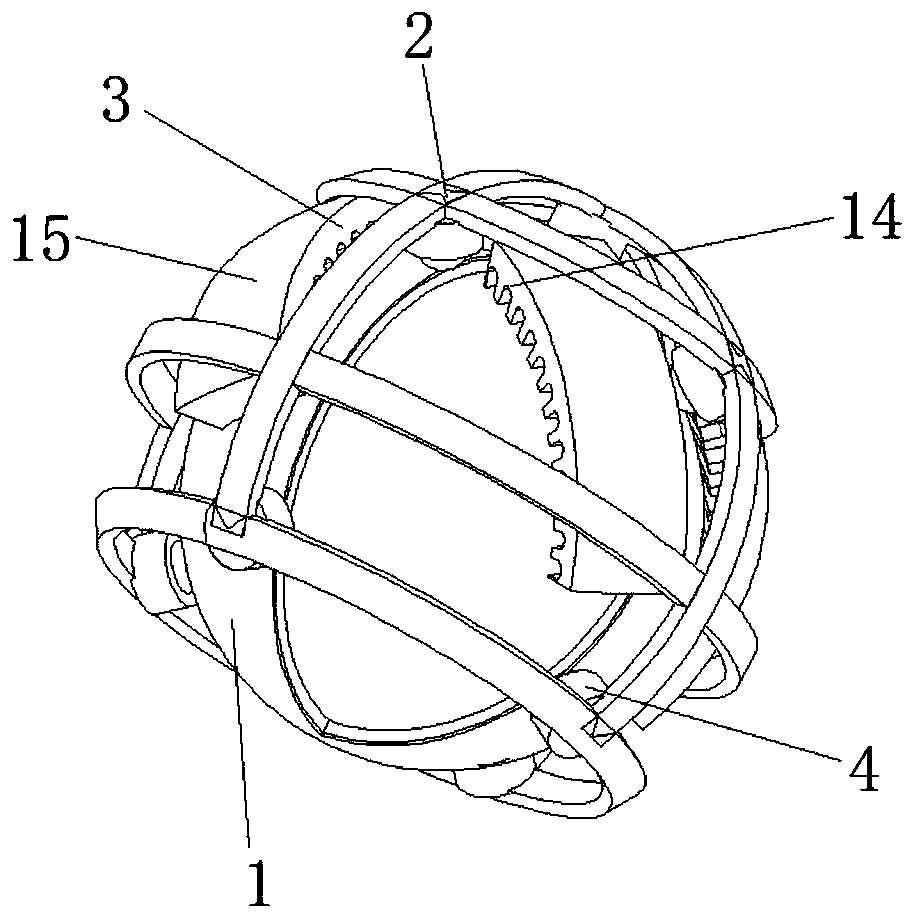

[0041] As an implementation, such as figure 1 As shown, a spherical induction motor without an output shaft includes a spherical housing 1, a stator support 2 and a stator unit 3 fixed on the stator support 2, the stator unit 3 is located between the stator support 2 and the spherical housing 1, the stator support 2 and the ball Bullseye bearings 4 are arranged between shells 1; bullseye bearings 4 include north pole bearings 5 and latitude coil bearings 7 groups, and, or south pole bearings 6, all bullseye bearings 4 are in contact with spherical shell 1; stator support 2 includes warp The warp ring 8 arranged in the direction and the weft ring 9 arranged in the weft direction, the weft coil bearing 7 groups include a plurality of bulls-eye bearings 4 fixed on the same weft ring 9; each stator unit 3 forms an angle with the warp, and all stator units The center of gravity of 3 is located on the same parallel, and the center of gravity of the stator unit 3 is located below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com