Wavelength thermal tuning device of external cavity semiconductor laser and synchronous thermal tuning method

A semiconductor and laser technology, applied in the field of external cavity semiconductor lasers, can solve problems such as complex circuit control, achieve continuous tuning, simple structure, and simple tuning mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

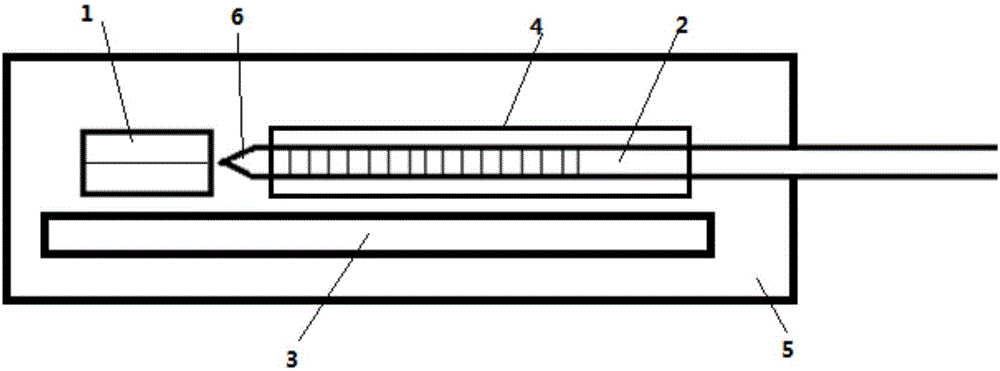

[0022] see first figure 1 , figure 1 It is the external cavity semiconductor laser device diagram of the present invention that adopts thermally-sensitized fiber Bragg grating. As can be seen from the figure, the wavelength thermal tuning device of the external cavity semiconductor laser of the present invention includes semiconductor gain chip 1. Enter Fiber Bragg Grating 2. The end surface of the gain chip 1 close to the grating is coated with an anti-reflection film to eliminate the resonant cavity effect of the gain chip itself. The other end is coated with a high reflection film, which is used to form a resonant cavity with the external cavity grating. Since the tapered lens 6 is directly ground and processed, it is integrated with the optical fiber and has a compact structure, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com