Method of extracting natural edible pigment

A food coloring and extraction method technology, applied in natural dyes, chemical instruments and methods, azo dyes, etc., can solve problems such as unstable product quality, poor product stability, and high production costs, and achieve easy control of process parameters and ensure stability The effect of high performance and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

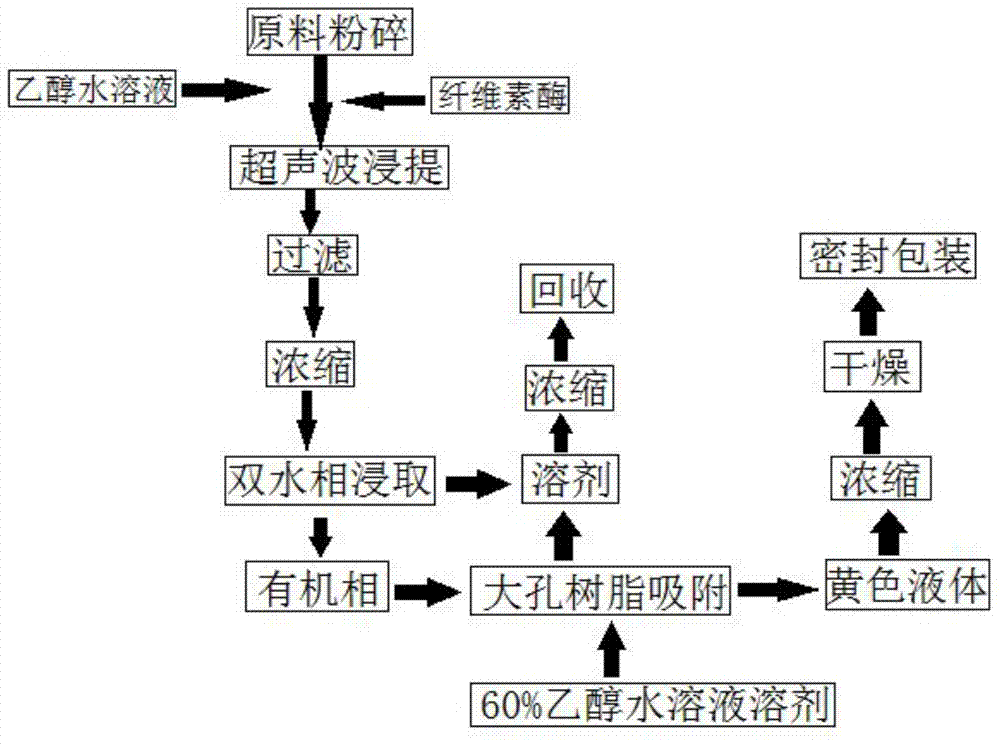

[0024] Such as figure 1As shown, a method for extracting natural food coloring, first adopts enzyme-assisted ultrasonic leaching yellow rice yellow pigment to obtain filtrate a; After 0.33, 0.34, 0.36, 0.38, 0.4, 0.42, 0.44, 0.46, 0.48 or 0.5 times, the organic phase is obtained through two-phase water system extraction; finally, the organic phase is extracted by macroporous resin adsorption and extracted by three technologies Combined, the extraction efficiency and extraction rate of the yellow pigment of the yellow rice flower are greatly improved, the product purity is improved, the process steps are simplified, and the production cost is reduced; in order to completely and properly extract the yellow pigment from the yellow rice flower, the extraction Extraction rate, promote the purity of product, reduce production cost, described enzyme-assisted ultrasonic leaching is to be the ethanol aqueous solution of 70% with yellow rice flower raw material and concentration, accord...

Embodiment 2

[0026] According to Embodiment 1, in order to make the yellow pigment in the raw material meet the requirements of extraction and reduce the extraction cost, the raw material of yellow rice flower is a kind of flower bud and tiktok; in order to dissolve the cellulose of the raw material epidermis of yellow rice flower, make All the pigments inside are exposed to achieve the purpose of extraction, and the enzyme is cellulase.

Embodiment 3

[0028] According to Embodiment 1, in order to make the yellow pigment in the raw material meet the requirements of extraction and reduce the extraction cost, the described yellow rice flower raw material is a mixture of flower buds and catkins; in order to dissolve the cellulose in the yellow rice flower raw material epidermis, make it All the pigments inside are exposed to achieve the purpose of extraction, and the enzyme is cellulase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com