Multi-stator arc linear motor capable of reducing torque fluctuation

A linear motor and multi-stator technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve the large torque fluctuation of the motor, affect the tracking performance of the motor, and be difficult to meet the needs of large-scale low-speed rotating equipment applications, etc. problem, to achieve the effect of small torque fluctuation, save processing, and reduce torque fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

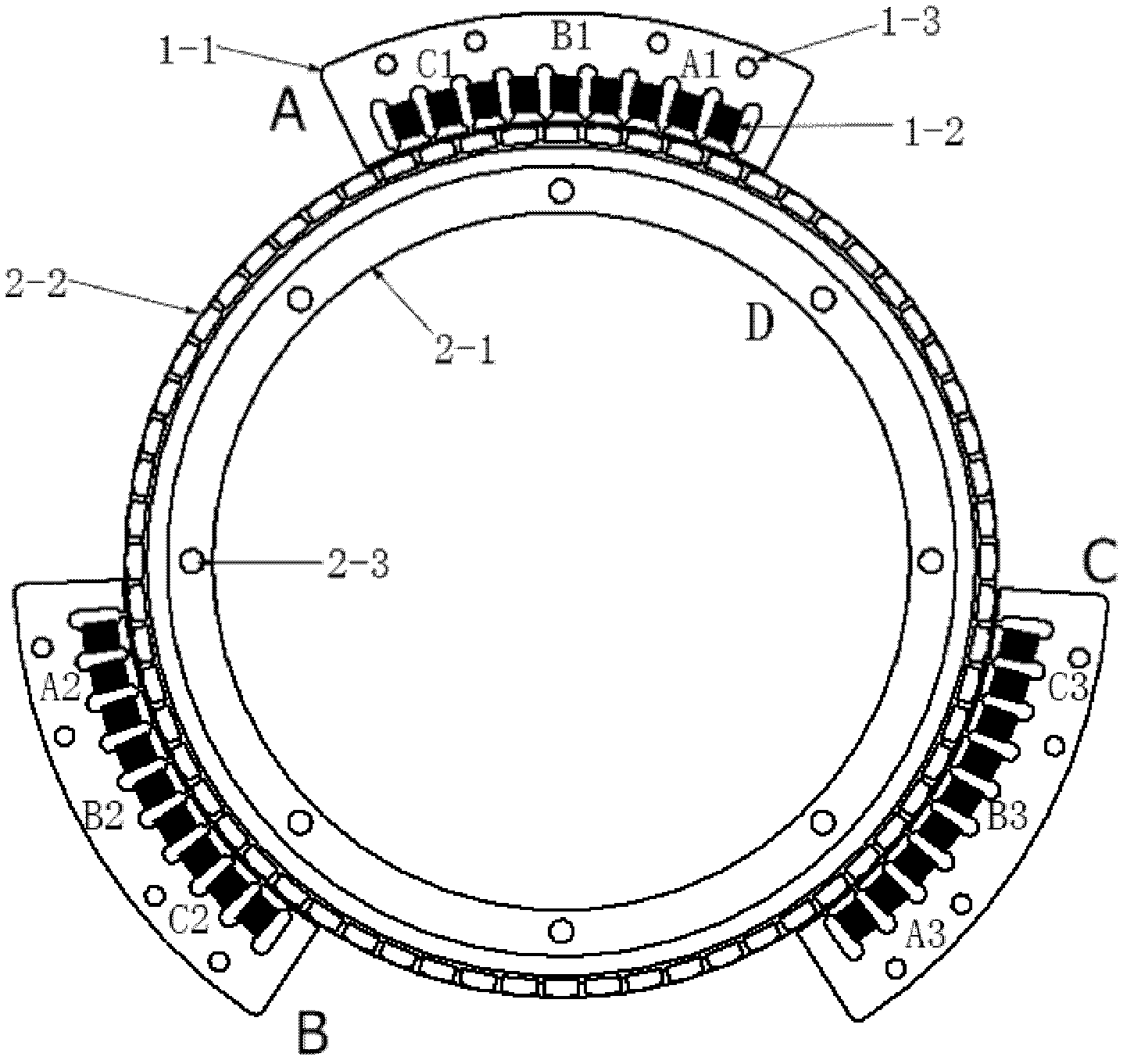

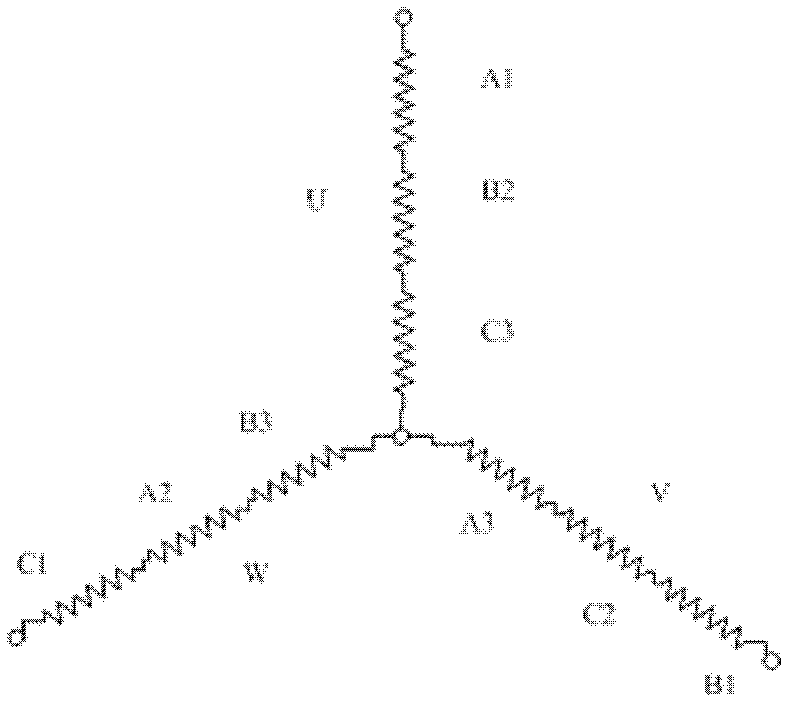

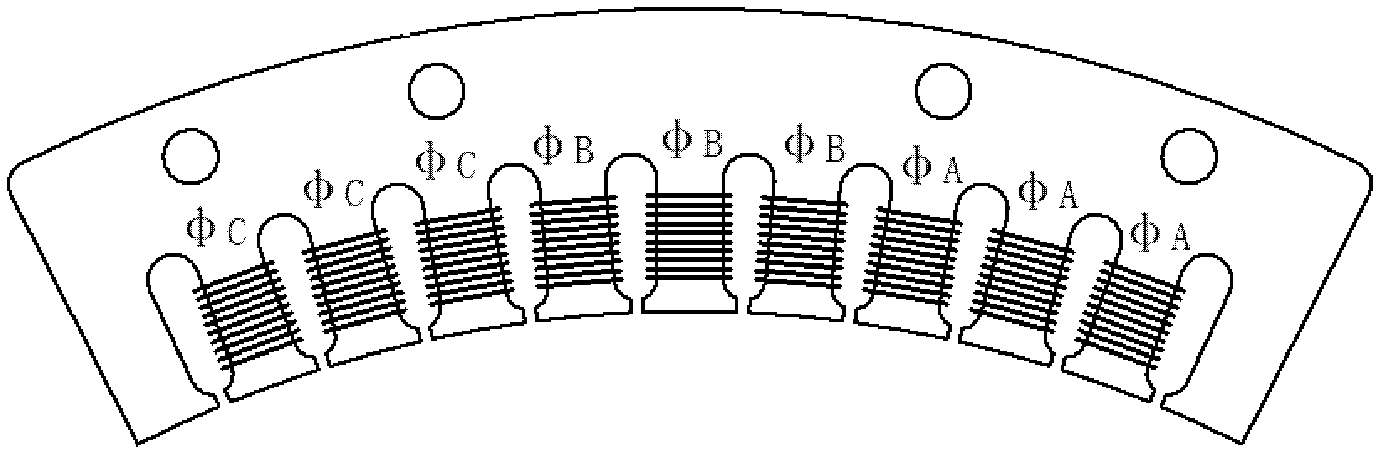

[0026] Such as figure 1 As shown, the arc-shaped linear motor of the present invention is a three-phase AC permanent magnet synchronous arc-shaped linear motor, which is assembled from three stators A, B, C and a rotor D with the same structure. The rotor D is composed of a rotor yoke 2-1 and 32 pairs (64 poles) of permanent magnets 2-2 attached to the rotor yoke 2-1. The three stators A, B, and C are arranged and installed at a mechanical angle of 120 degrees apart in space. The three stators can be processed and transported separately, and then installed together when in use. Each stator A or B or C is respectively fixed on the stationary part of the installation equipment through four φ9 through holes 1-3, and the rotor D is fixed on the rotating part of the installation equipment through eight φ11 positioning holes 2-3. The outer radius of the rotor D is 198.8mm, and the inner radius is 178mm. The rotor yoke 2-1 is made of No. 45 steel with good magnetic permeability. Eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com