Permanent magnet synchronous motor back potential harmonic suppressing method and permanent magnet synchronous motor

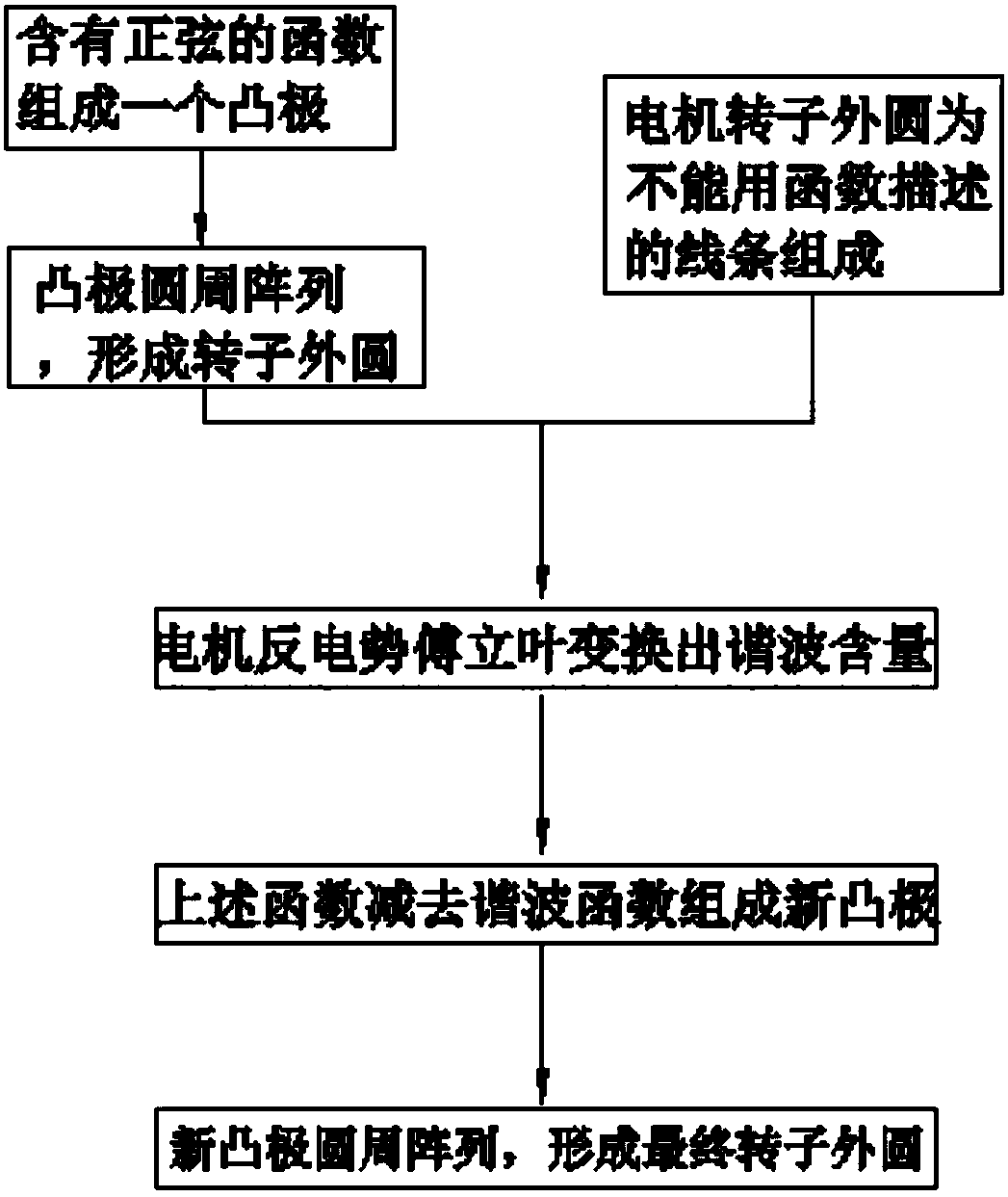

A permanent magnet synchronous motor, harmonic suppression technology, applied in permanent magnet synchronous motor back EMF harmonic suppression, permanent magnet synchronous motor field, can solve the problem that there is no way to suppress the back EMF harmonic and weaken the permanent magnet synchronous motor back EMF harmonic And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

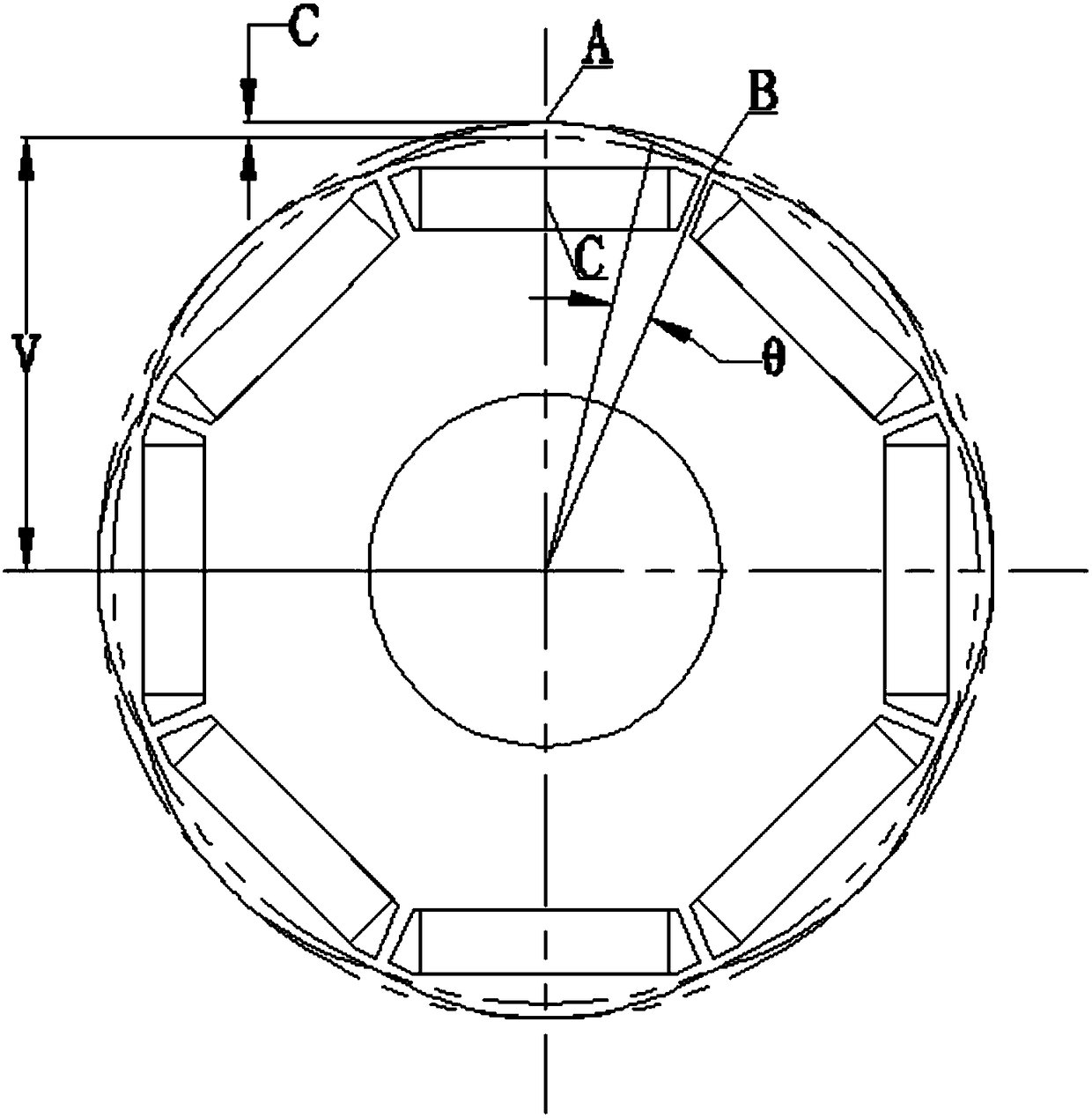

[0013] The motor in the embodiment of the present invention has 12 slots and 8 poles, IPM structure, and sine wave control. The air gap is 0.4mm.

[0014] Functions involving sine take: Among them, v and c are taken as 20.9mm and 0.7mm respectively. Draw a salient pole, and for this salient pole circular array, the array number is equal to the pole number 8.

[0015] The connection line between the apex of the salient pole and the center of the circle passes through the geometric center of the magnet, and the connection line between the lowest point of the salient pole and the center of the circle passes through the boundary between two adjacent magnetic steels. The minimum distance from the vertex of the salient pole to the inner circle of the stator is 0.4mm in the air gap of the motor. Draw the shape of the motor rotor figure 1 .

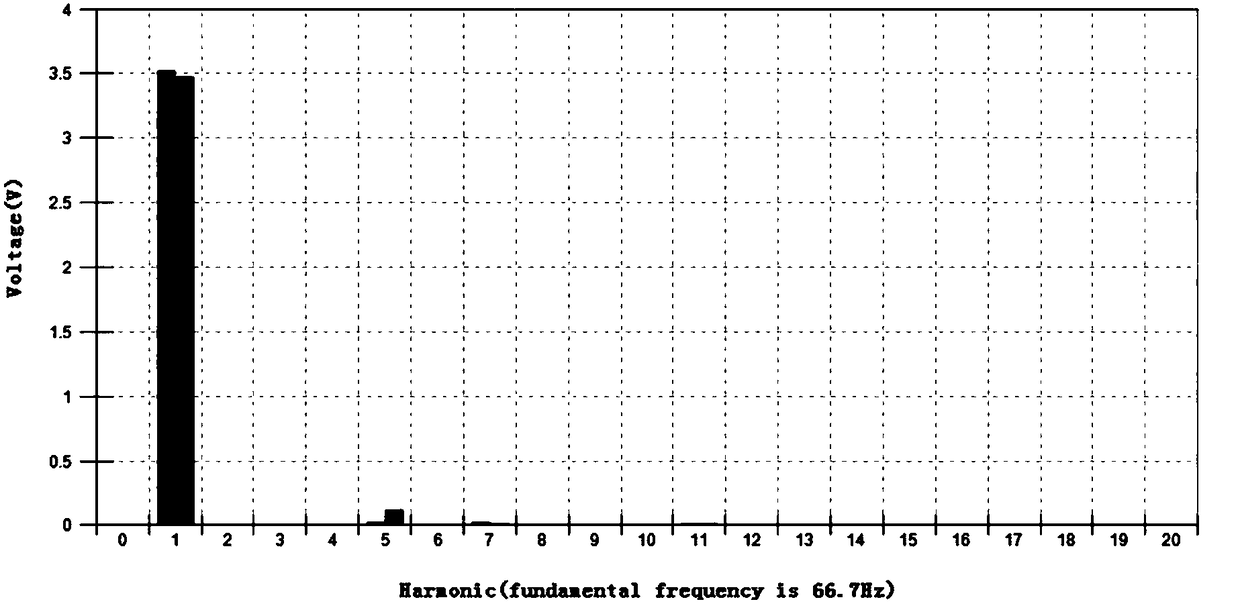

[0016] In the case that the stator and rotor have no oblique poles, test the back EMF waveform of the motor containing the above rotor, an...

Embodiment 2

[0020] The motor in the embodiment of the present invention has 12 slots and 10 poles, IPM structure, and sine wave control. The air gap is 0.2mm.

[0021] Functions involving sine take: Among them, v and c are taken as 21mm and 0.7mm respectively. Draw a salient pole, and for this salient pole circular array, the number of arrays is equal to 10 poles.

[0022] The connection line between the apex of the salient pole and the center of the circle passes through the geometric center of the magnet, and the connection line between the lowest point of the salient pole and the center of the circle passes through the boundary between two adjacent magnetic steels. The minimum distance from the vertex of the salient pole to the inner circle of the stator is 0.2mm for the air gap of the motor. Draw the shape of the motor rotor.

[0023] In the case that the stator and rotor have no oblique poles, test the back EMF waveform of the motor containing the above rotor, and perform Fourie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com