A soft starter for single-phase motor and single-phase motor with same

A single-phase motor and soft starter technology, which is applied to the starter of a single single-phase induction motor, motor generator/starter, electric/electric converter, etc., can solve the problem of low reliability and long starting time of soft starters , starting current harmonics and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It is believed that the above and other objects, features and advantages of the present invention will become clearer through the following detailed description of specific embodiments of the present invention in conjunction with the accompanying drawings.

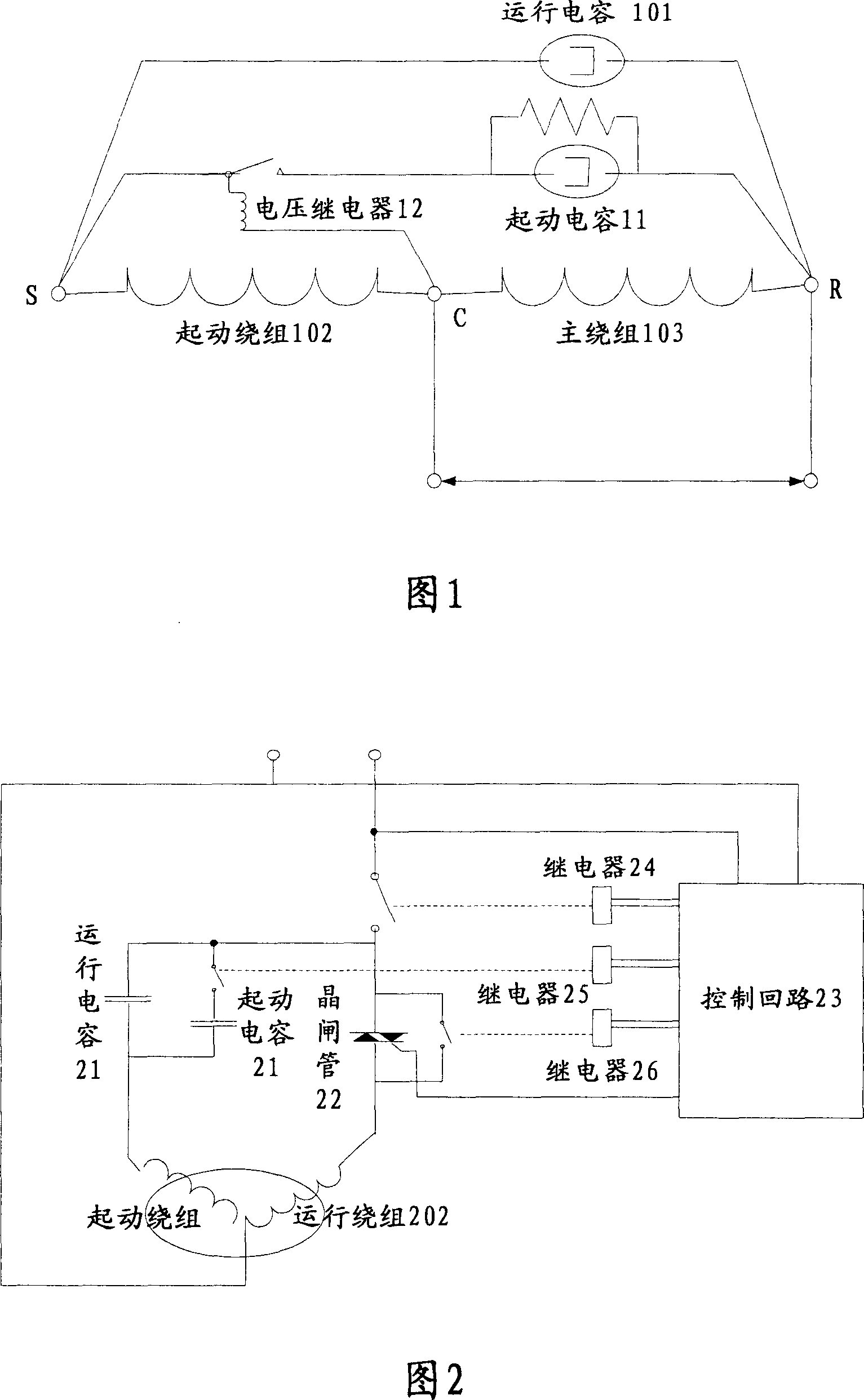

[0026] Fig. 1 and Fig. 2 are single-phase motor starters in the prior art, which have been described in detail in the background technology section, and their descriptions are omitted here.

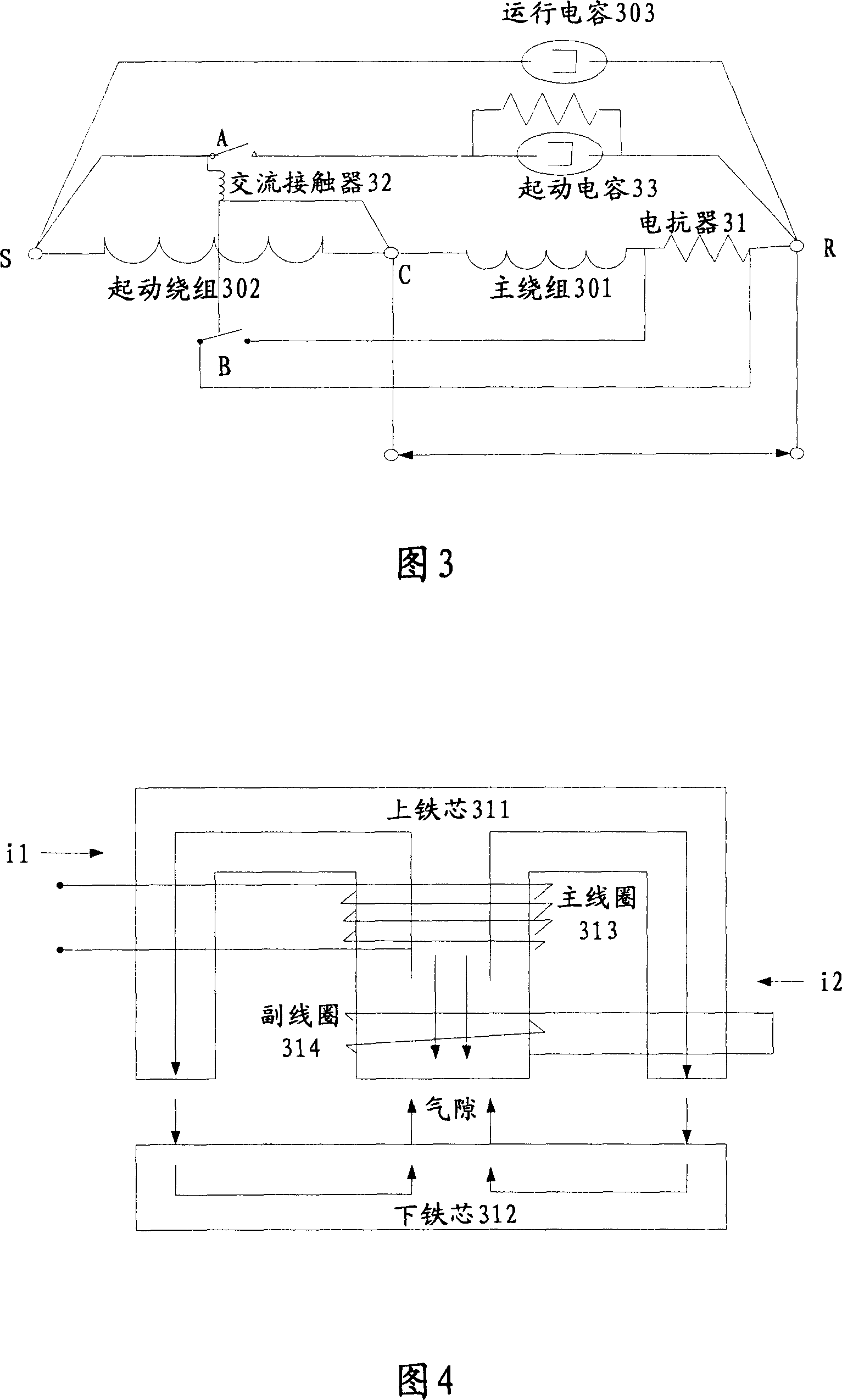

[0027] Fig. 3 is a schematic diagram of a single-phase motor soft starter according to an embodiment of the present invention. As shown in Figure 3, a single-phase motor at least includes a main winding 301, a starting winding 302 and a running capacitor 303, wherein the main winding 301 and the starting winding 302 are connected in series, and the connection point is C, and the running capacitor 303 is connected with the main winding 301 and the running capacitor 301 connected in series. The starting windings 302 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com