Asymmetric double three phase camber line permanent-magnet synchronous electrical machine

A permanent magnet synchronous motor, dual-three-phase technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuits, electric components, etc., can solve the problems of high cost and low efficiency, and achieve improved utilization, Improve stability and facilitate manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

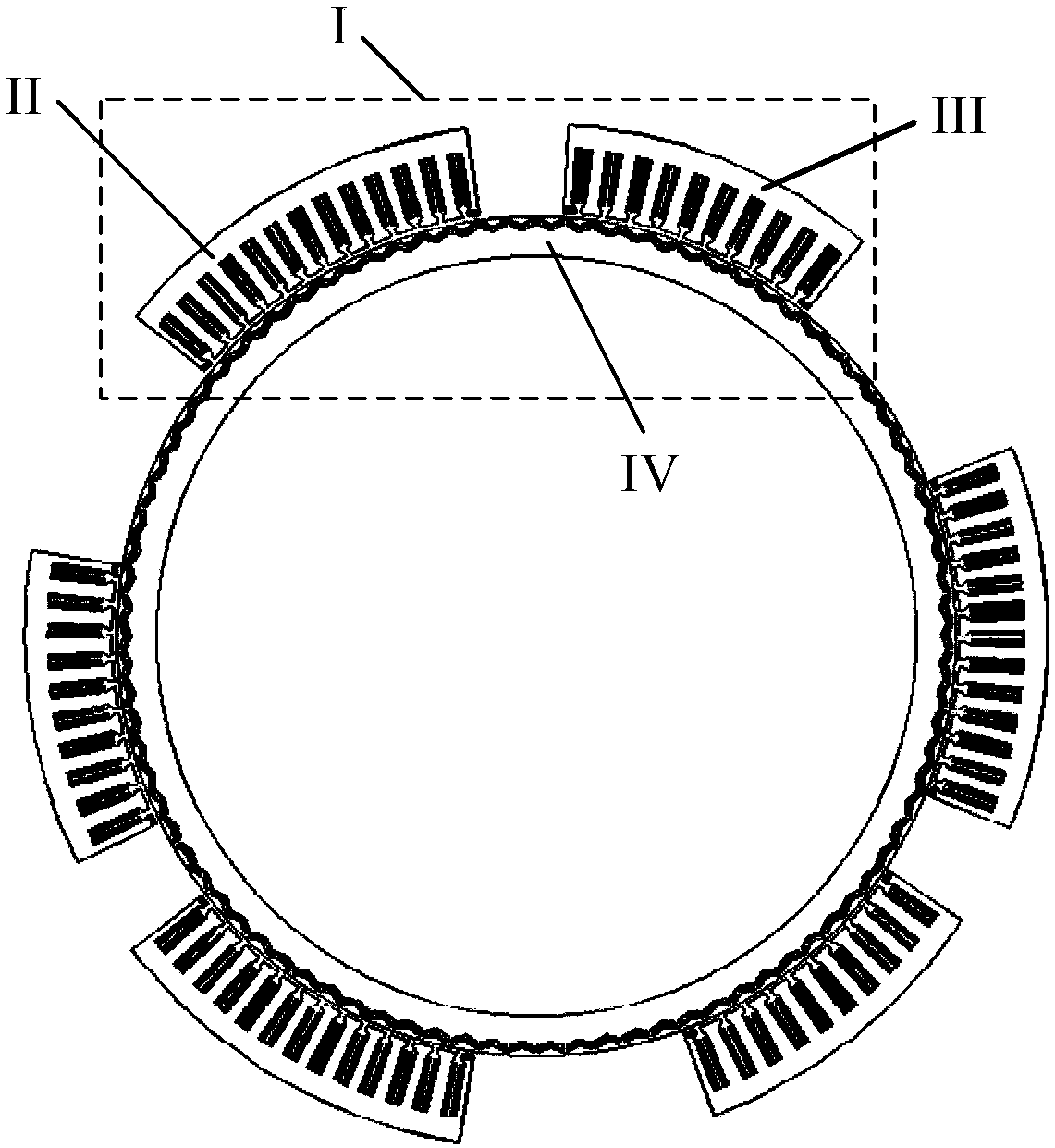

[0025] The asymmetric double three-phase arc permanent magnet synchronous motor, its specific implementation is as follows figure 1 As shown, it mainly includes two parts: stator assembly I and rotor IV.

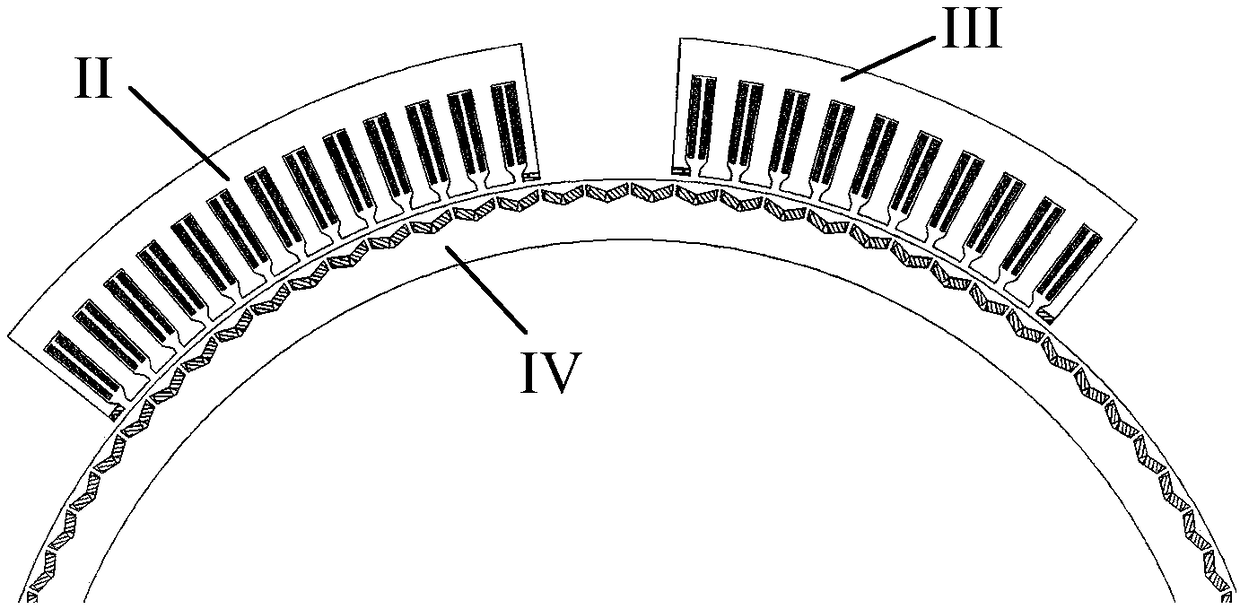

[0026] The stator assembly part such as figure 2 As shown, it consists of a 12-slot stator module II and a 9-slot stator module III.

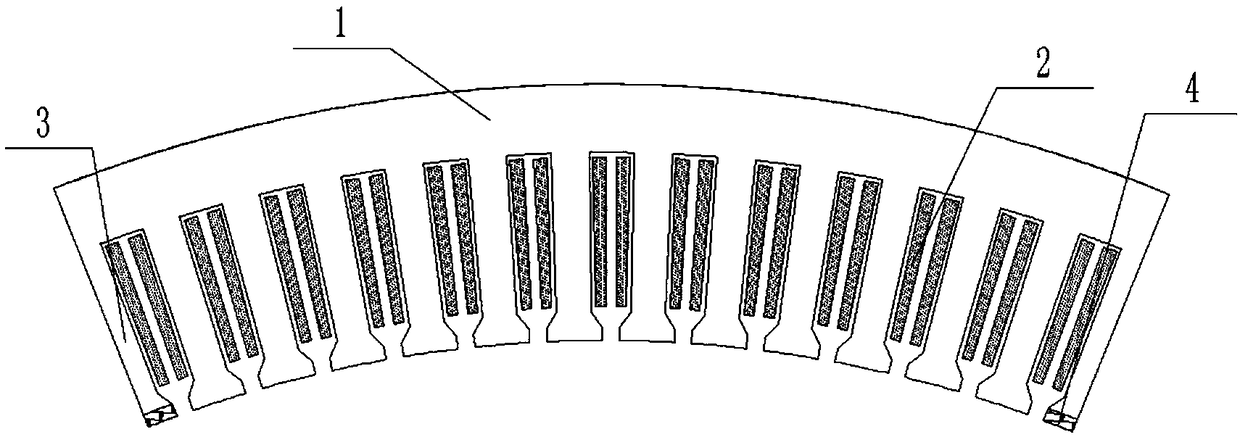

[0027] The 12-slot stator module part is as image 3 As shown, it is composed of a 12-slot stator core 1, a 12-slot armature coil 2, a 12-slot auxiliary tooth 3, and a 12-slot low magnetic energy product permanent magnet 4.

[0028] 9-slot stator module part such as Figure 4 As shown, it is composed of a 9-slot stator core 5, a 9-slot armature coil 6, a 9-slot auxiliary tooth 7 and a 9-slot low magnetic energy product permanent magnet 8.

[0029] The rotor part is like Figure 5 As shown, it is composed of a "V"-shaped arrangement of permanent magnets 9, a magnetic isolation bridge 10, and a rotor core 11.

[0030] The asymmetrical double three-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com