Novel direct current driving turntable structure

A DC drive, mesa technology, applied in the direction of DC commutator, magnetic circuit shape/style/structure, electric components, etc., can solve the problems of difficult to achieve large load, high-frequency response simulation requirements, etc., to achieve small torque fluctuation, reduce cost, the effect of achieving high-frequency response and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

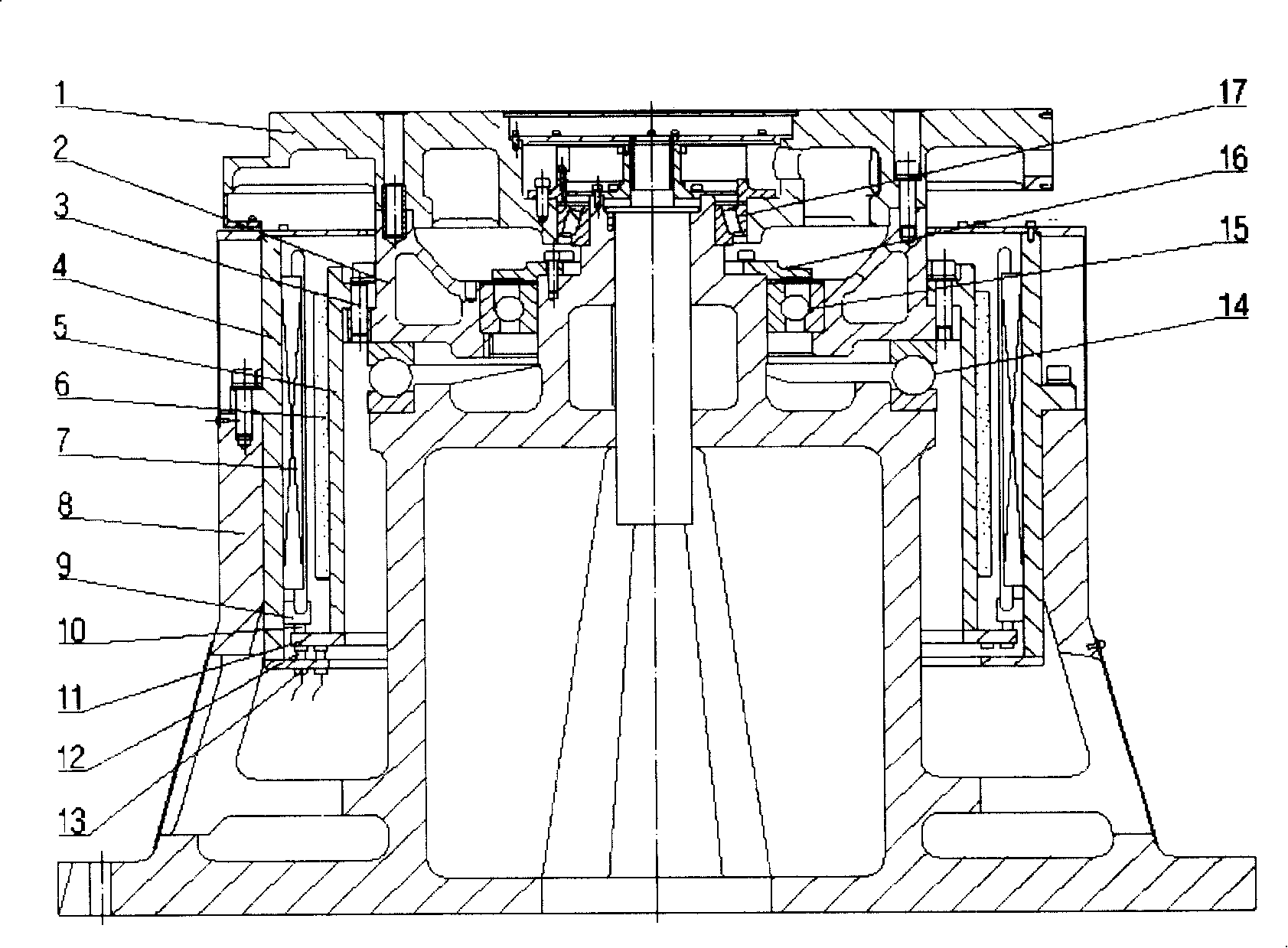

[0006] The turntable shown in the figure consists of a working table 1, a main shaft 2, a stator 4, a rotor 5, a magnetic steel 6, a winding and an iron core 7, a frame 8, a commutator 9, a commutator brush 10, and a brush holder with a conductive ring 11. Conductive ring brush 12, incoming line terminal 13, thrust ball bearing 14, angular contact ball bearing 15, tapered roller bearing 17, bearing end cover 16, etc. The motor stator 4 is installed on the frame 8, and the inner side of the stator 4 is installed There are windings and iron core 7, the commutator 9 is at the lower end of the winding; the incoming line terminal 13 and the conductive ring brush 12 are fixed at the lower end of the stator 4; the motor rotor 5 is fixed on the main shaft 2, and the working surface 1 is connected with the main shaft 2 by bolts 3 Connected, the magnetic steel 6 is fixed on the rotor 5, the brush holder 11 with a conductive ring is installed at the bottom of the rotor 5, the brush 10 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com