Flat limited angle torque motor

A limited-angle, torque motor technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of large axial volume, unsuitable for miniaturization, lightweight systems, and low space occupancy rate of limited-angle motors, to achieve Small moment of inertia, improved utilization of internal dimensions, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

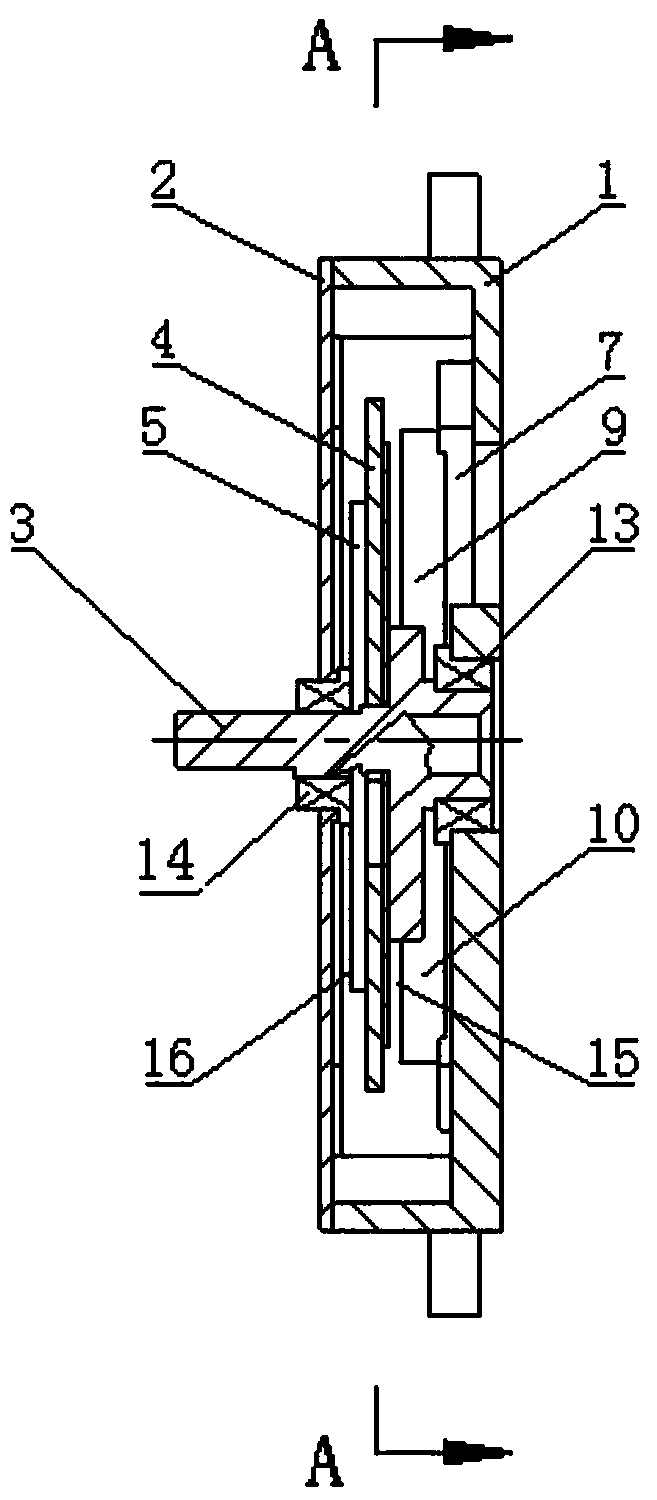

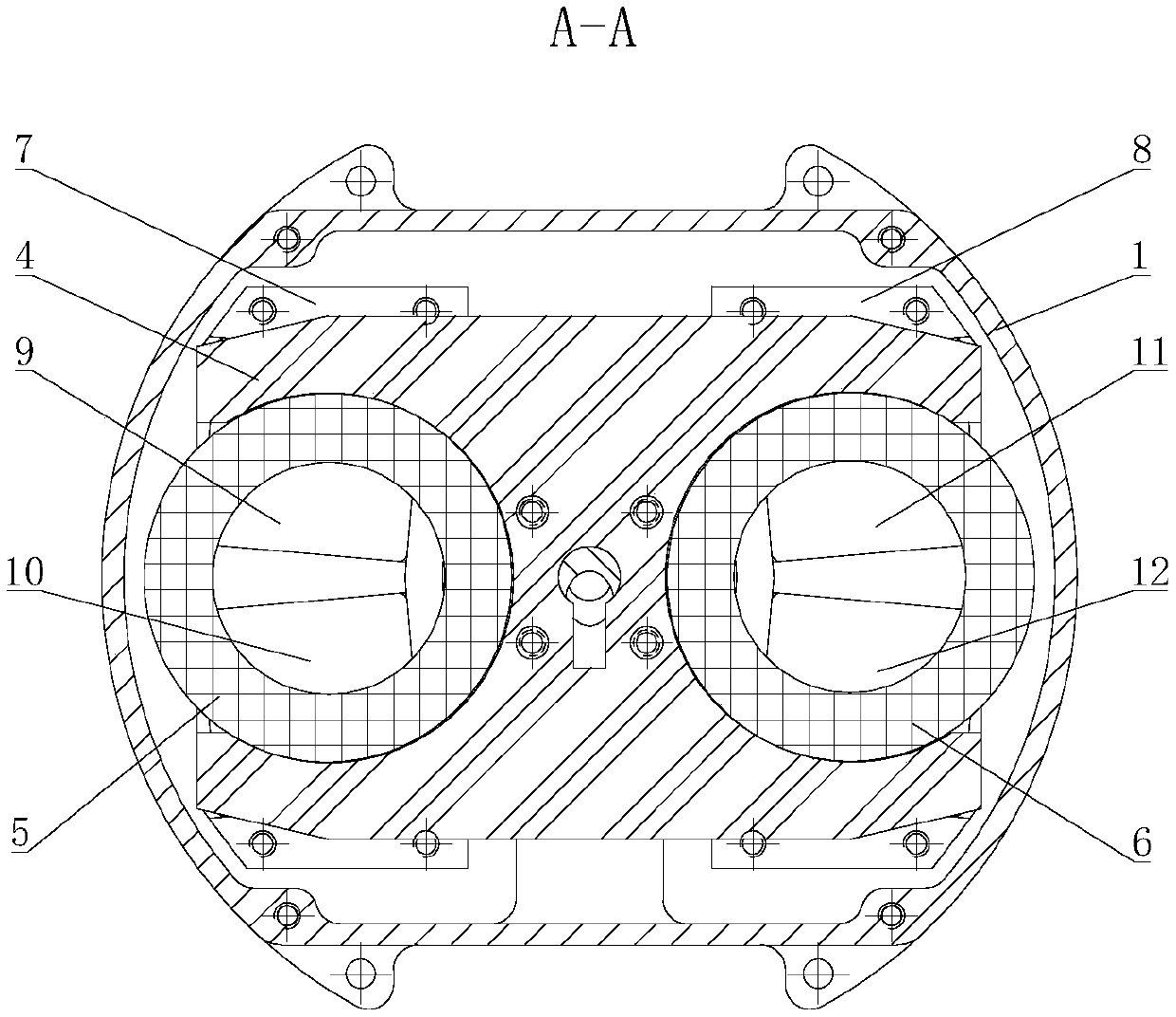

[0029] A flat type limited angle torque motor, mainly composed of a gland 1, a casing 2, a motor shaft 3, a bearing 13, a bearing 2 14, a magnetic steel seat 7, a magnetic steel seat 2 8, a magnetic steel 9, and a magnetic steel Two 10, magnetic steel three 11, magnetic steel four 12, rotor skeleton 4, coil one 5 and coil two 6 are composed.

[0030] The gland is installed on the casing. There are installation holes in the middle of the gland 1 and the casing 2, which are used to install the outer rings and flanges of the bearing 13 and bearing 2 14 respectively. There are mounting seats at both ends of the motor shaft 3, respectively. The bearing inner ring used to install bearing one 13 and bearing two 14 cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com