Motor vehicle lighting device for producing band-shaped light-emitting surface

A technology for lighting equipment and motor vehicles, applied in lighting and heating equipment, motor vehicles, mechanical equipment, etc., can solve problems such as stains, high weight, high cost, etc., and achieve the effect of less parts and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

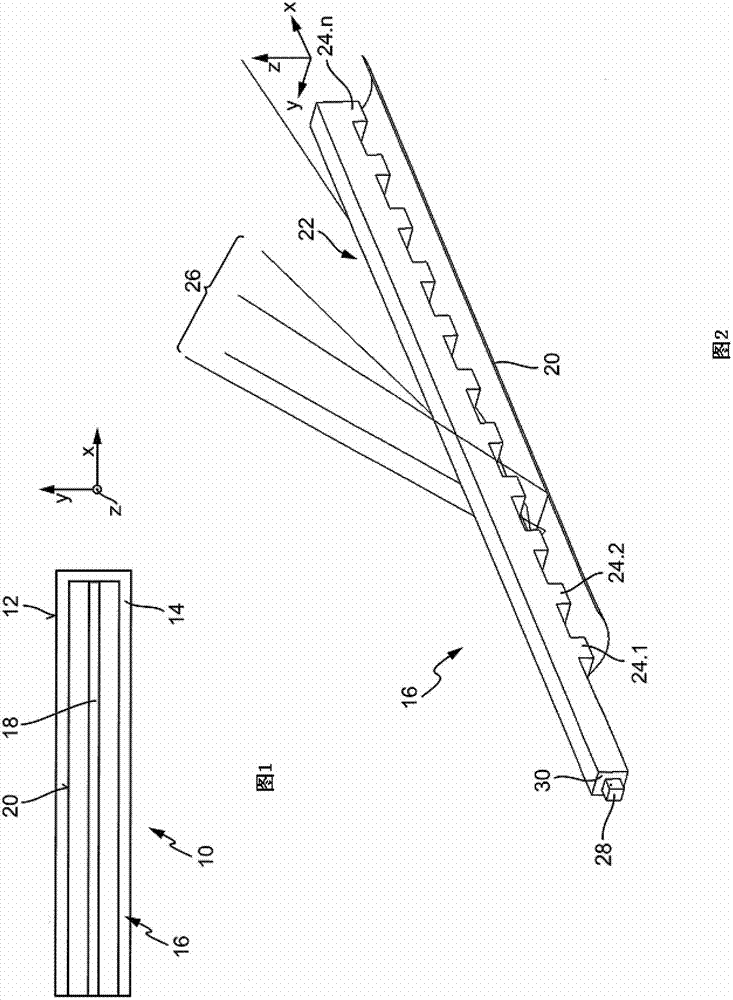

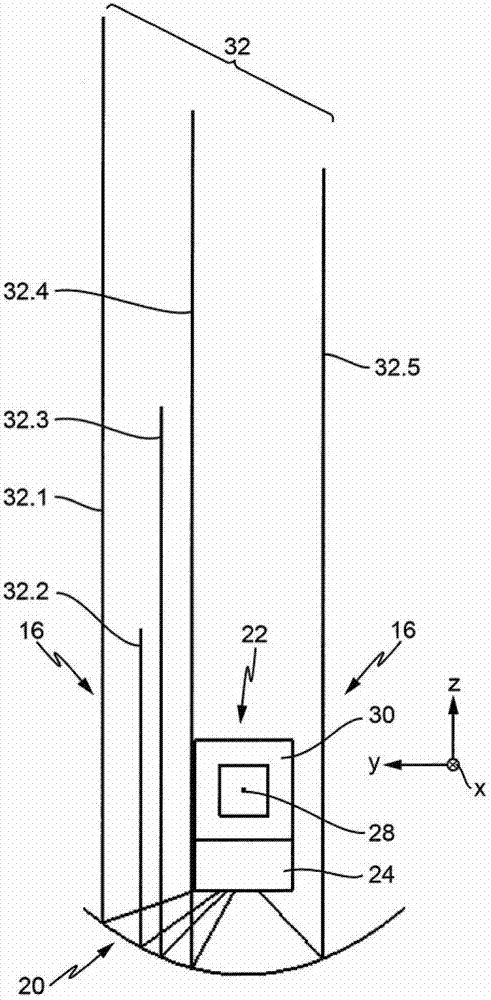

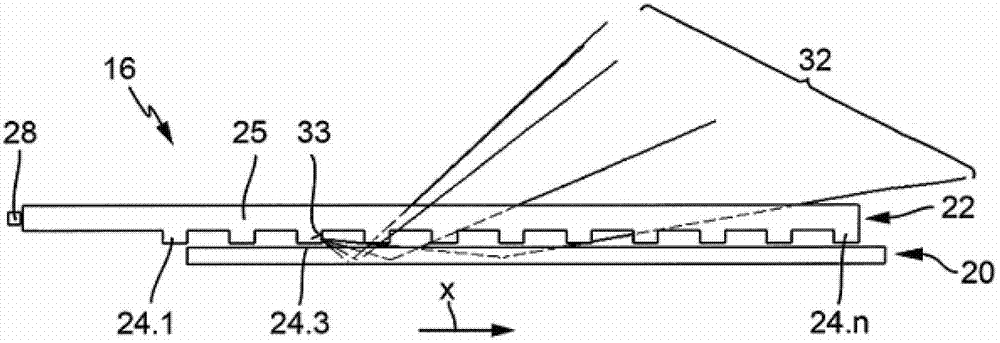

[0046] figure 1 The motor vehicle lighting device 10 is shown in detail in the front view with a housing 12 and a light output opening which is covered by a transparent dust cover 14 . Behind the dust cover 14 is an optical module 16 disposed inside the casing 12 . The optical module 16 has a longitudinally elongated light guide 18 with a figure 1 Slot-shaped reflector 20 located behind light guide 18 in the line of sight direction in the front view of . In the exemplary embodiment shown, the lighting device 10 is a daytime running light, a separate flashing light, a high-mounted brake light or a light that fulfills another signaling function. In an alternative configuration, the light module 16 can also be integrated into the headlight with the headlight function. In this regard, the lighting device according to the invention may be a headlamp or a luminaire. Headlamps are used to illuminate the roadway or unlit objects on the roadway, while lamps have the function of ale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com