Method for constructing a driver's cab of a commercial vehicle

A technology for cabs and commercial vehicles, applied in the field of cabs, can solve problems such as unergonomic and time-consuming, and achieve the effect of improving pre-grouping, efficient and flexible assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

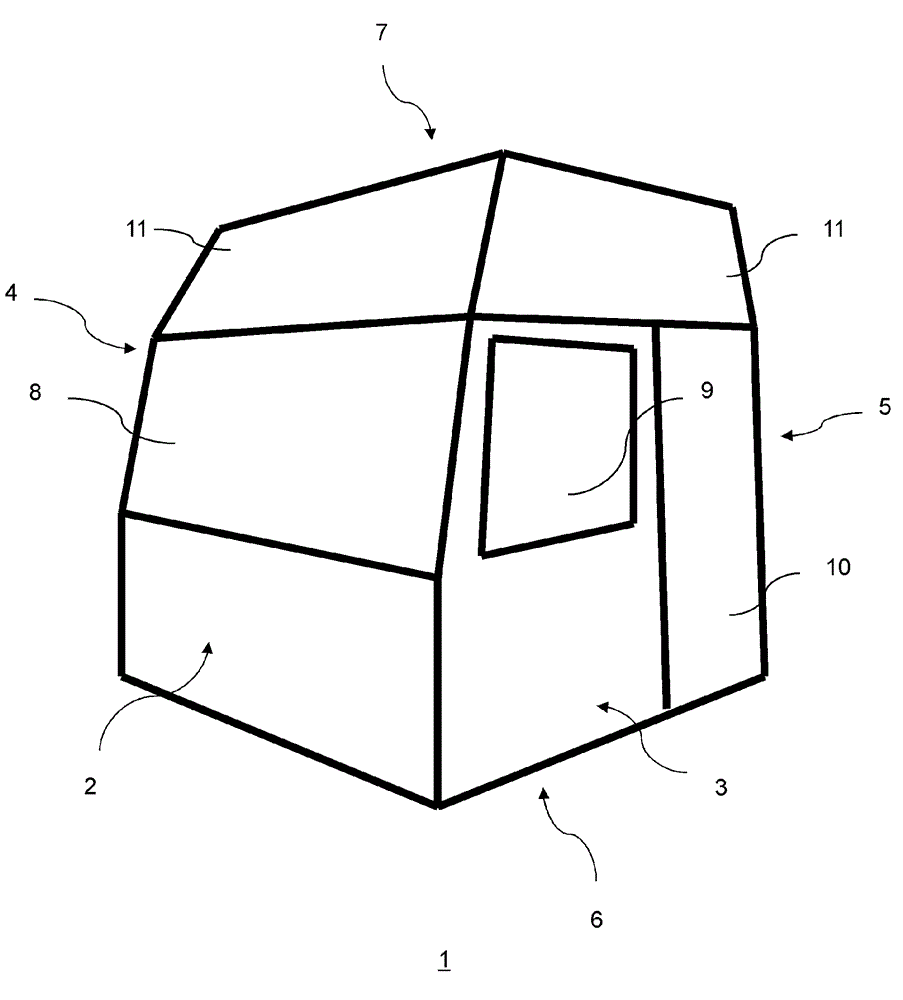

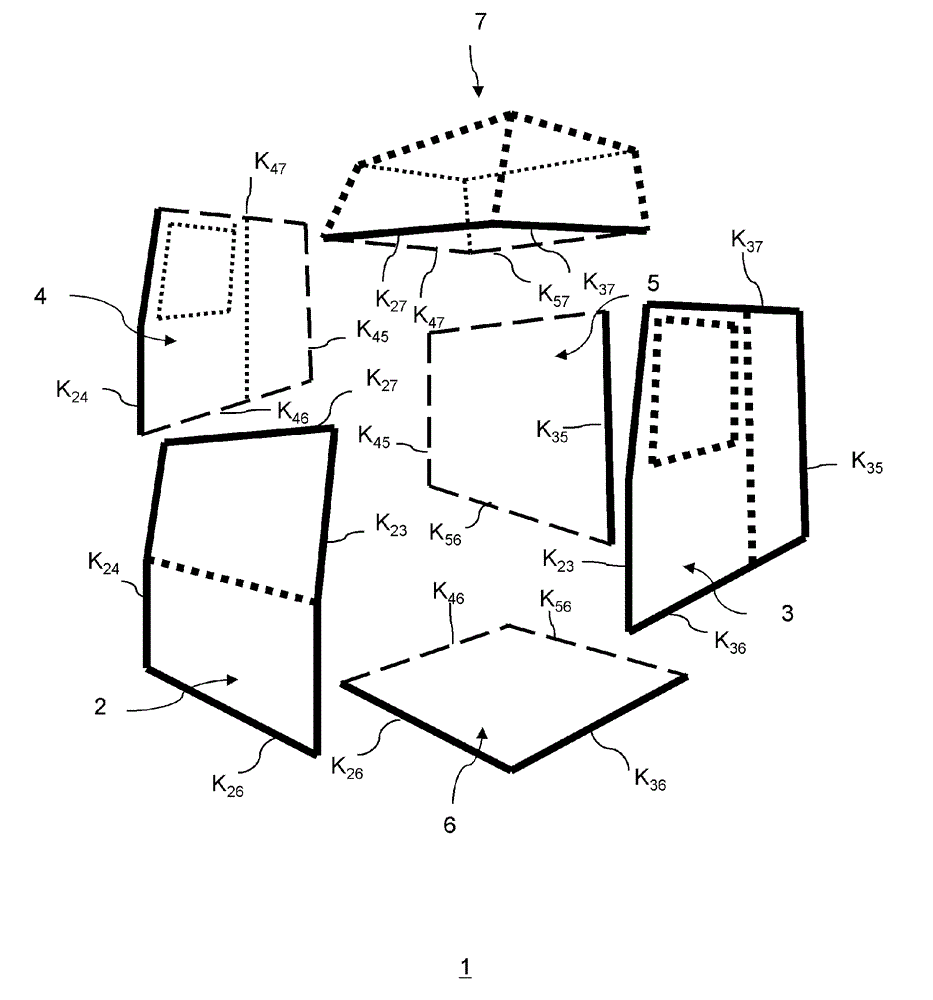

[0032] figure 1 and figure 2 A schematic perspective view of a modularly constructed driver's cab 1 is shown. and figure 1 Instead, in figure 2 Also shows edges that are not visible in the selected perspective as dashed lines.

[0033] The driver's cab 1 shown is composed of a front wall 2 , two opposite side walls 3 , 4 , a rear wall 5 , a roof module 7 and a floor part 6 . The individual wall modules 2 to 7 are connected together and generally consist of steel sheets. The side walls 3 , 4 have cutouts 8 to 10 for the windshield, side windows and driver's door. A profiled roof structure 7 adjoins the side walls 3 , 4 and the front and rear walls 2 , 5 .

[0034] exist image 3 In , the edges adjoining or connecting the respective adjacent side walls 3, 4 are highlighted. exist image 3 In , the visible connection edges are indicated by thick solid lines, while in image 3 Connection edges that are not visible in the perspective view of are indicated by dashed line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com