Sheet material and case housing prepared from the sheet material

A technology for boards and bags, applied in applications, luggage, synthetic resin layered products, etc., can solve the problems of cumbersome production process, inability to use corner waste, waste of raw materials, etc., to save materials and reduce weight , The effect of eliminating environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

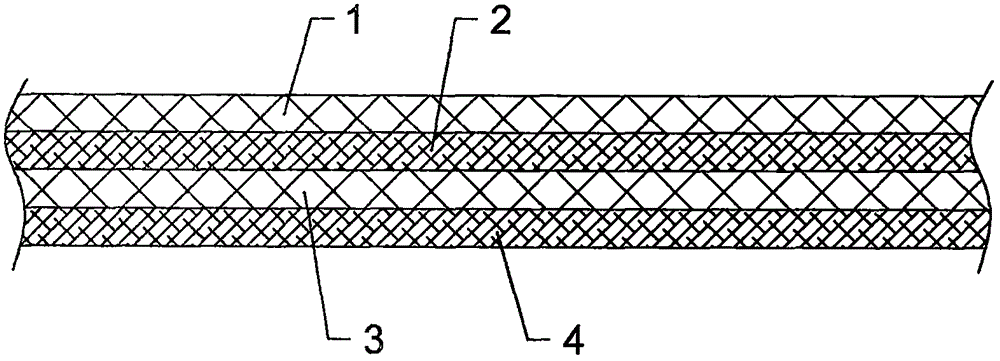

[0029] Embodiment 1, the first cloth layer 2 is woven from chemical fiber yarns that have undergone vacuum coating treatment, and the chemical fiber yarns are coated with metallic colors after vacuum coating treatment, so that the board and the bags made of the board have a strong metallic texture .

Embodiment approach 2

[0030] Embodiment 2, the first cloth layer 2 is woven from filaments and / or threads that have not undergone vacuum coating treatment. Colors and patterns to showcase.

Embodiment approach 3

[0031] Embodiment 3, the first fabric layer 2 is woven from chemical fiber filaments treated by vacuum coating and filaments and / or threads not treated by vacuum coating, and the chemical fiber filaments treated by vacuum coating can partially appear on the cloth surface. Chemical fibers can be coated with different metal colors through vacuum coating treatment, so that soft bags can also have a metallic texture. The chemical fiber filaments treated by vacuum coating and the filaments or threads not treated by vacuum coating are woven into cloth together, so that the chemical fiber filaments treated by vacuum coating are woven into the cloth in a wave-like undulating manner, and the chemical fiber filaments treated by vacuum coating during compression molding can be It has a certain extension and is not easy to be broken, which can greatly improve the yield of compression molding, and the wire or thread that has not been vacuum-coated has good adhesion to the plastic layer, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com