Conveying device for sectional bars

A technology for conveying equipment and profiles, applied in the stacking of objects, conveyor objects, transportation and packaging, etc., can solve the problems of easy interference and low degree of automation in measurement, and achieve a large measurement range, improve accuracy, and facilitate control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

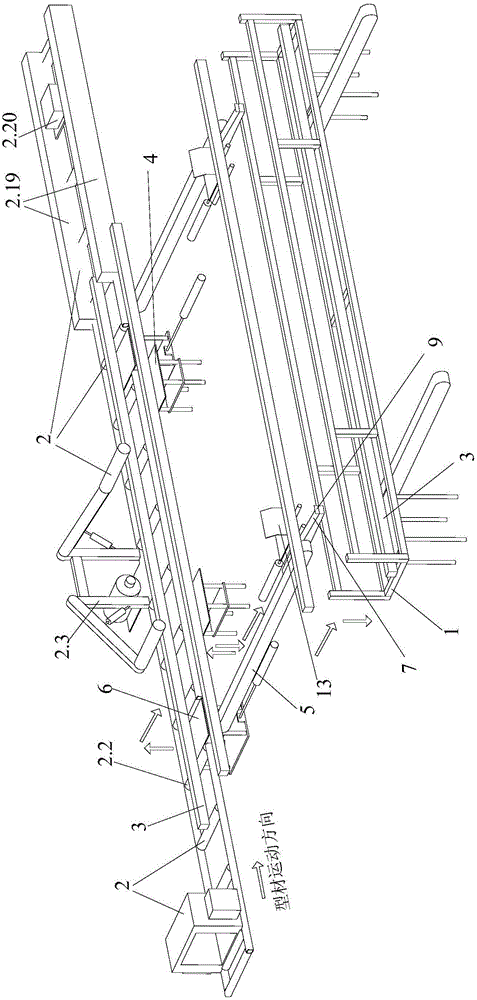

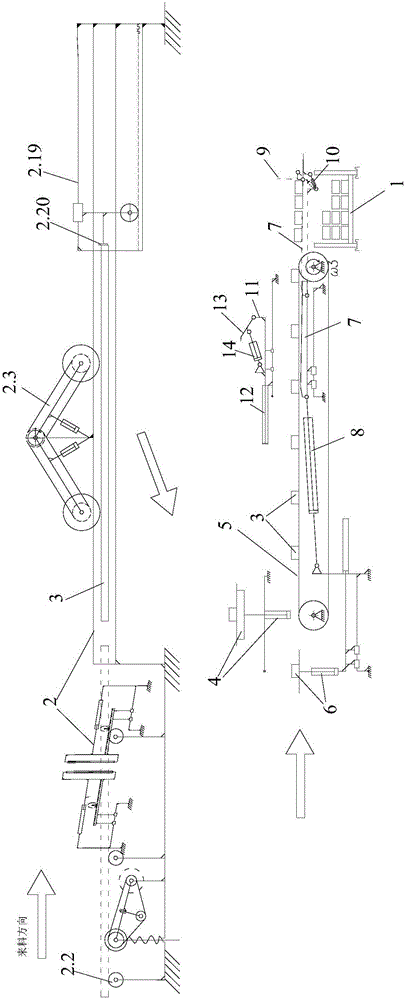

[0047] Such as Figures 1 to 3 As shown, a profile transmission device of the present invention is used to transmit the profile 3 to the profile storage frame 1; it includes:

[0048] Profile longitudinal feeding mechanism 2, used to measure the length and width of profile 3 and transfer profile 3 to the transverse transfer station;

[0049] Profile lateral feeding mechanism, used to measure the weight of the profile 3 at the horizontal transfer station and transfer the profile 3 to the material sorting station;

[0050] The profile sorting mechanism is used to arrange the profiles 3 on the sorting station, so that the sorted profiles 3 can fall into the profile storage frame 1;

[0051] And the control mechanism, the control mechanism is connected with the profile vertical feeding mechanism 2, the profile horizontal feeding mechanism and the profile material sorting mechanism.

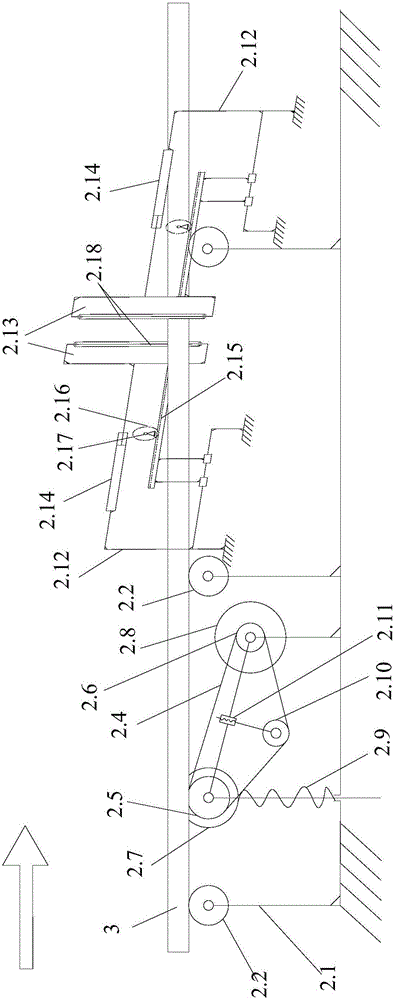

[0052] The profile longitudinal feeding mechanism 2 of the present invention includes a frame bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com