Spring brake chamber capable of preventing braking force superposition

A spring brake air chamber, braking force technology, applied in the direction of brake transmission, brake, brake actuator, etc., can solve the problem of increased maintenance cost, complicated pipeline connection, differential relay valve or two-way single There are many problems such as many ports to the valve, so as to reduce the configuration cost, save the installation space, and reduce the failure mode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

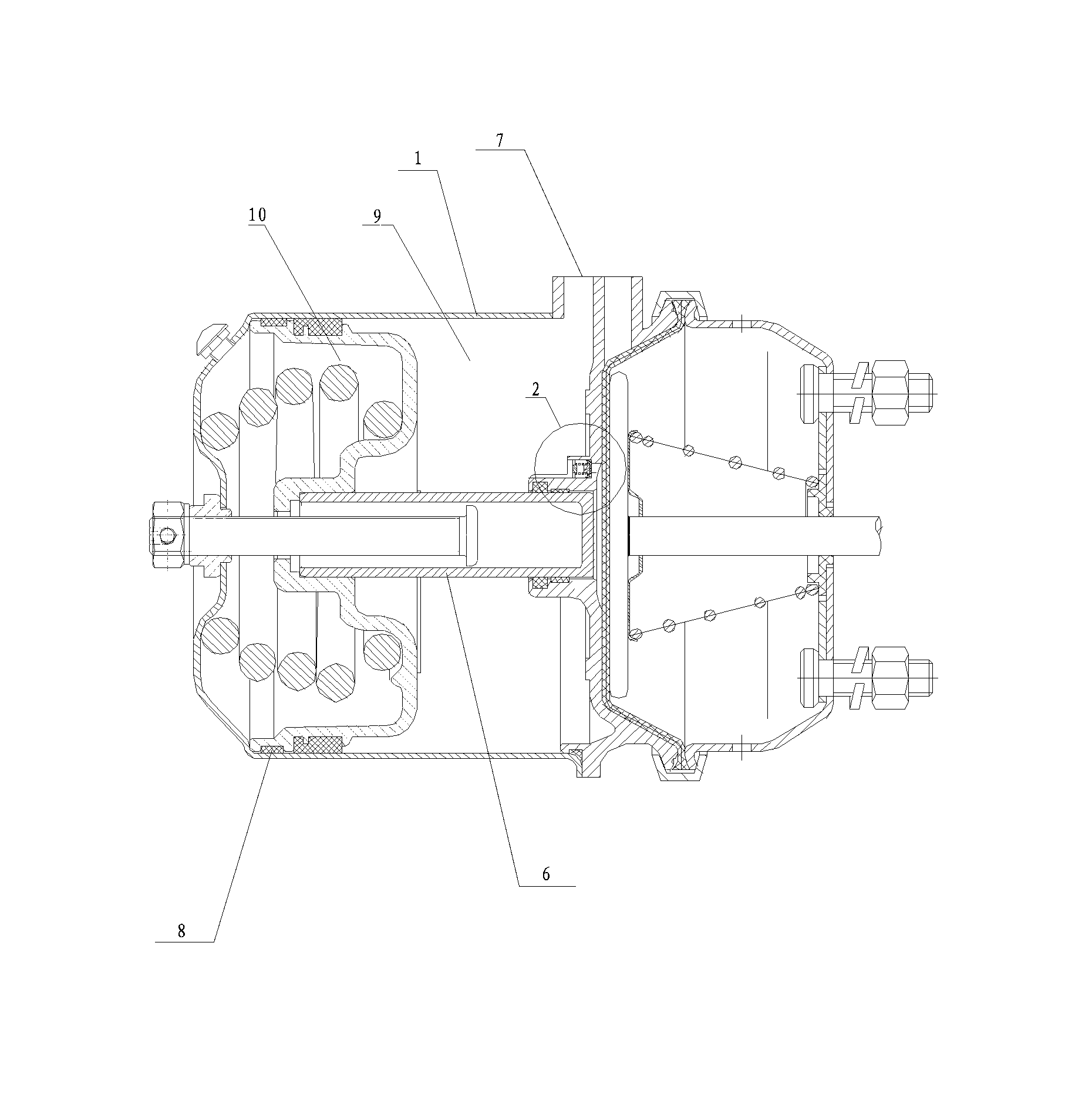

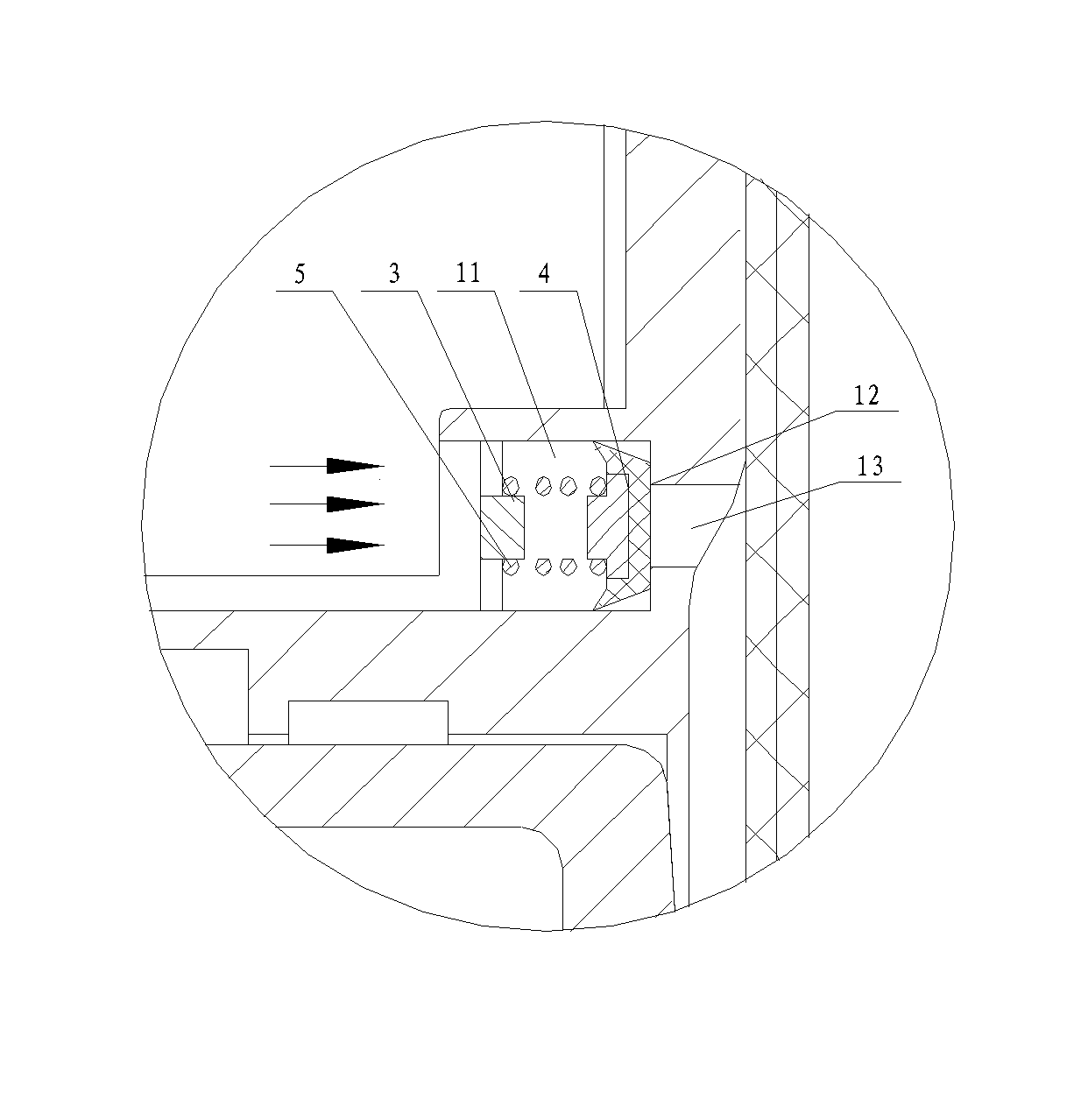

[0027] Such as figure 1 and 2 As shown, an anti-braking force superimposed spring brake air chamber includes a spring brake air chamber 1 and a bypass valve 2 arranged on the middle housing at the piston shaft 6 in the spring brake air chamber 1, The bypass valve 2 includes a valve seat 3 , a one-way valve 4 and a return spring 5 .

[0028] When driving, the anti-braking force superimposed spring brake air chamber parking brake port 7 always has air pressure acting on the parking brake chamber 9, and the energy storage spring 10 is compressed under the action of the air pressure, and is in the parking brake release position; At the same time, the air pressure of the parking brake chamber 9 acts on the bypass valve chamber 11 of the bypass valve 2, and the air pressure acts on the check valve 4. The air pressure of the check valve 4 in the parking brake chamber 9 and the return spring 5 The vent 12 is closed under the action.

[0029] When the service brake is performed, the...

Embodiment 2

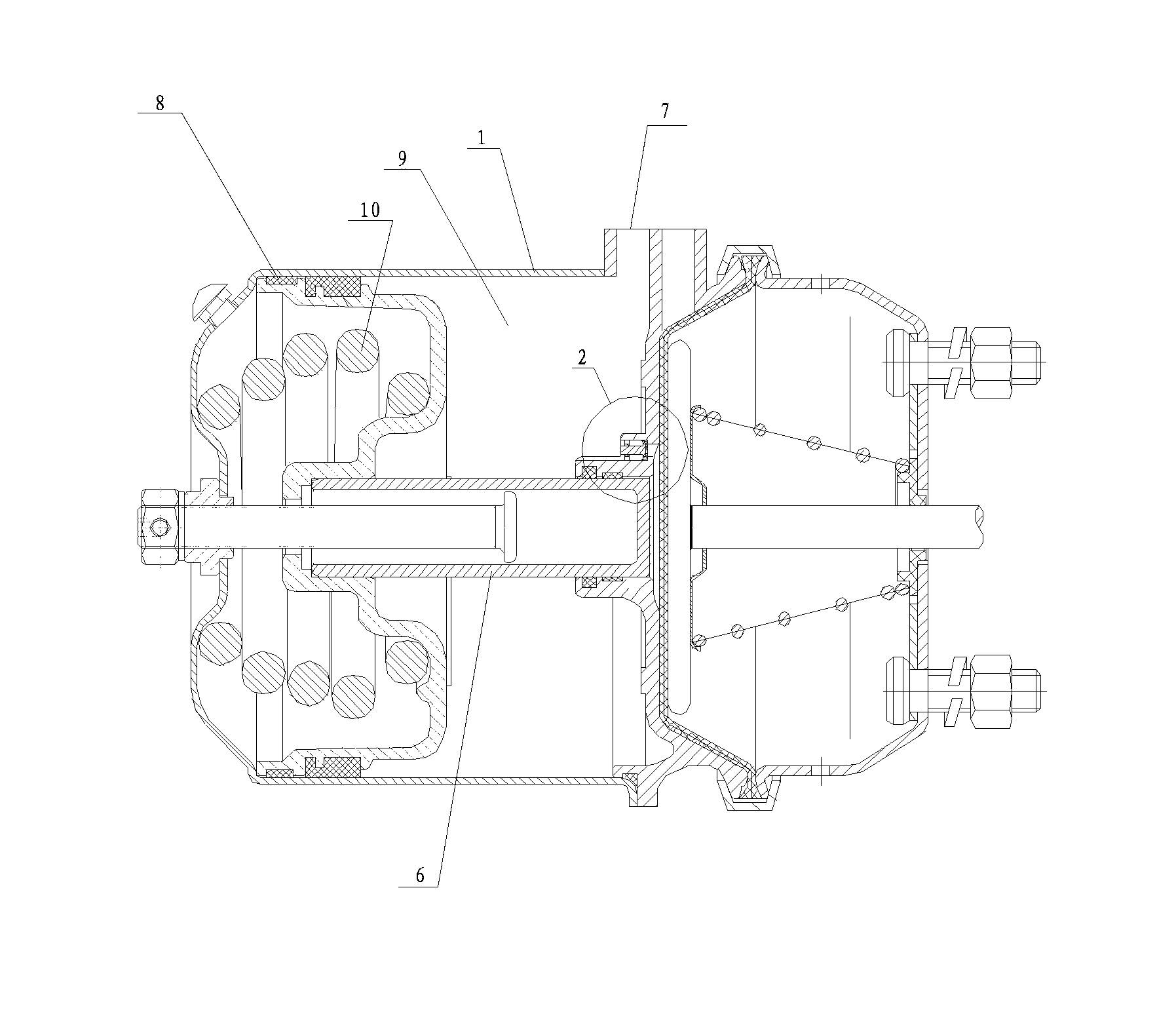

[0034] Such as image 3 and 4 As shown, an anti-braking force superimposed spring brake air chamber includes a spring brake air chamber 1 and a bypass valve 2 arranged on the middle housing at the piston shaft 6 in the spring brake air chamber 1, The bypass valve 2 includes a valve seat 3 and a one-way valve 4 .

[0035] When driving, the anti-braking force superimposed spring brake air chamber parking brake port 7 always has air pressure acting on the parking brake chamber 9, and the energy storage spring 10 is compressed under the action of the air pressure, and is in the parking brake release position; At the same time, the air pressure of the parking brake chamber 9 acts on the bypass valve chamber 11 of the bypass valve 2, and the air pressure acts on the one-way valve 4, and the one-way valve 4 closes the air port 12 under the action of the air pressure of the parking brake chamber 9. .

[0036] When the service brake is performed, the air pressure from the bicycle br...

Embodiment 3

[0041] Such as Figure 5 As shown, an anti-braking force superimposed spring brake air chamber includes a spring brake air chamber 1 and a bypass on the middle housing at the parking brake port 7 in the spring brake air chamber 1 A valve 2 , the bypass valve 2 includes a valve seat 3 , a one-way valve 4 and a return spring 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com