Integrated circuit test seat and its test interface

A technology for testing interfaces and integrated circuits, which is applied to electronic circuit testing, components of electrical measuring instruments, and electrical measurement. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

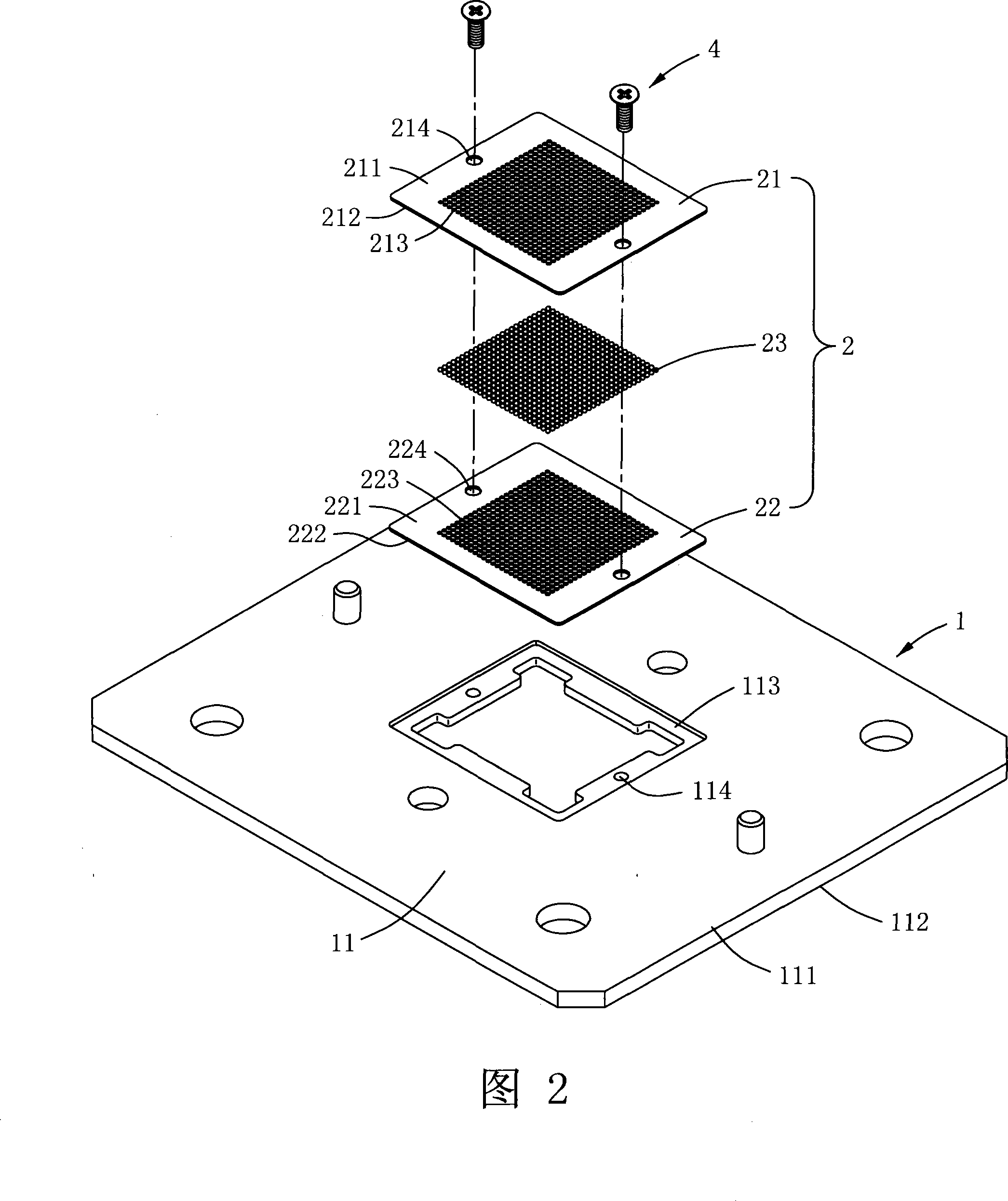

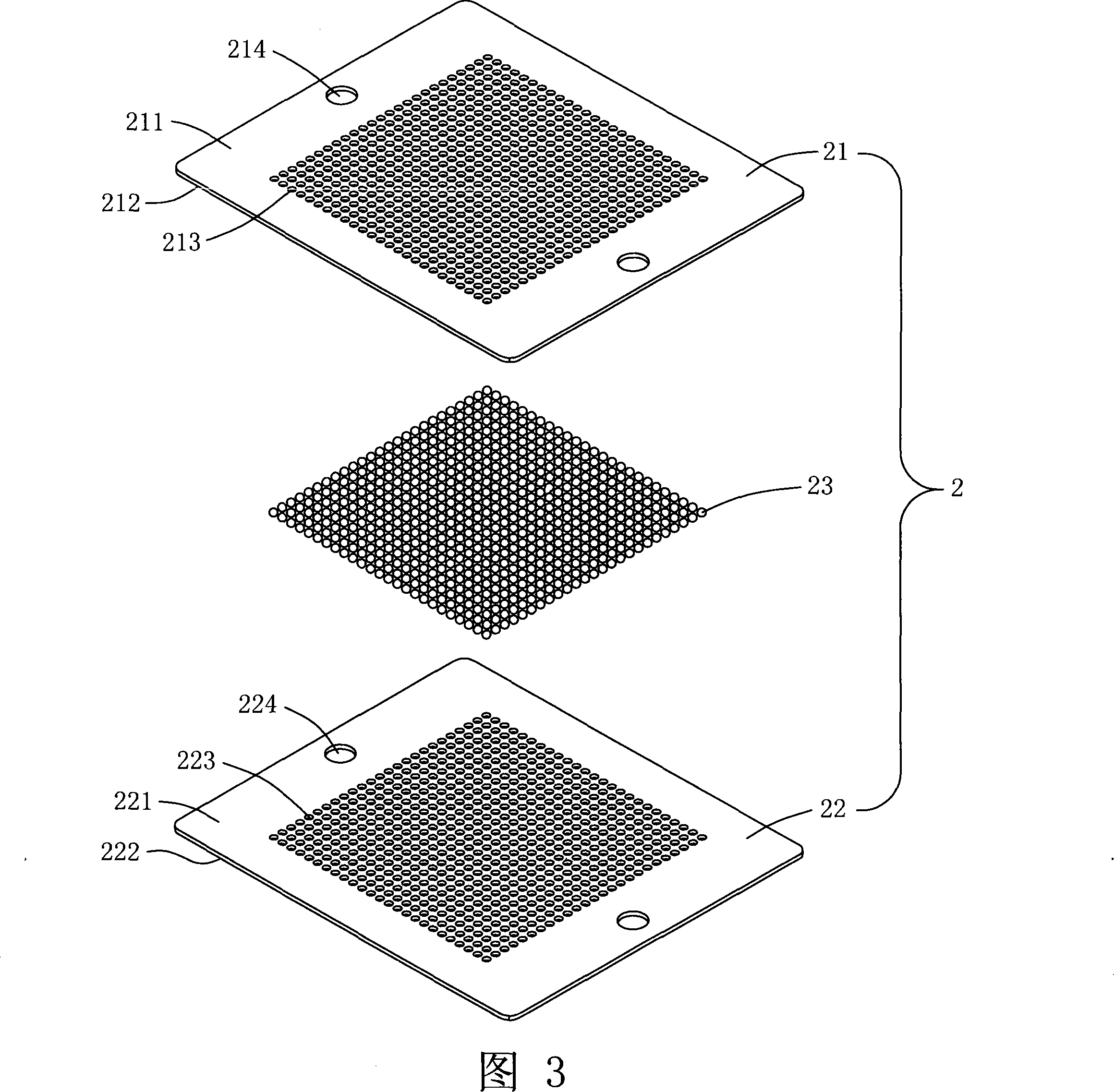

[0022] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

[0023] Please refer to FIG. 2 and FIG. 3 , wherein FIG. 2 is a three-dimensional exploded schematic view of the integrated circuit (IC) test socket 1 of the present invention, and FIG. 3 is a schematic exploded structure schematic diagram of the IC test interface 2 of the IC test socket 1 of the present invention. The test socket 1 is disposed between an IC package to be tested (refer to the IC package 3 shown in FIG. 5 ) and a test board (not shown), and is used for electrical testing of the IC package. The IC test socket 1 includes a test socket body 11 having a top surface 111 , a bottom surface 112 and an opening 113 passing through the top surface 111 and the bottom surface 112 . Two positioning holes 114 are defined at two opposite inner edges of the opening 113 .

[0024] The IC test interface 2 is disposed in the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com